Modified supported copper-rhenium bimetal catalyst and preparation method and application thereof

A bimetallic catalyst, supported technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem of low selectivity and low product selectivity of reaction substrate conversion rate It can solve the problems such as polymerization and service life reduction, and achieve the effects of excellent hydrogenation activity, low reduction temperature and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

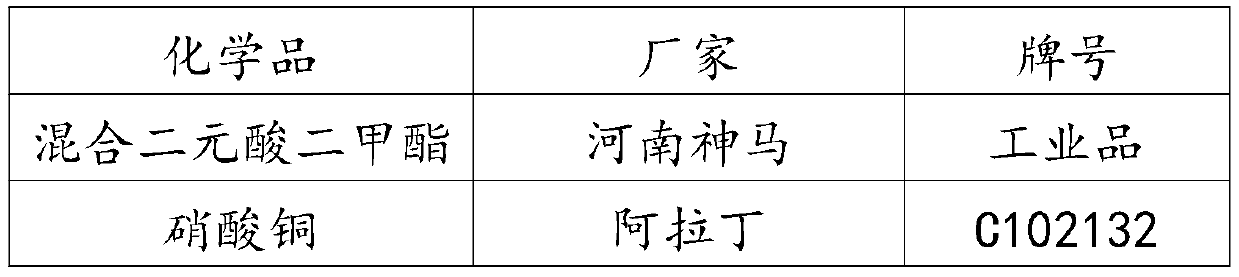

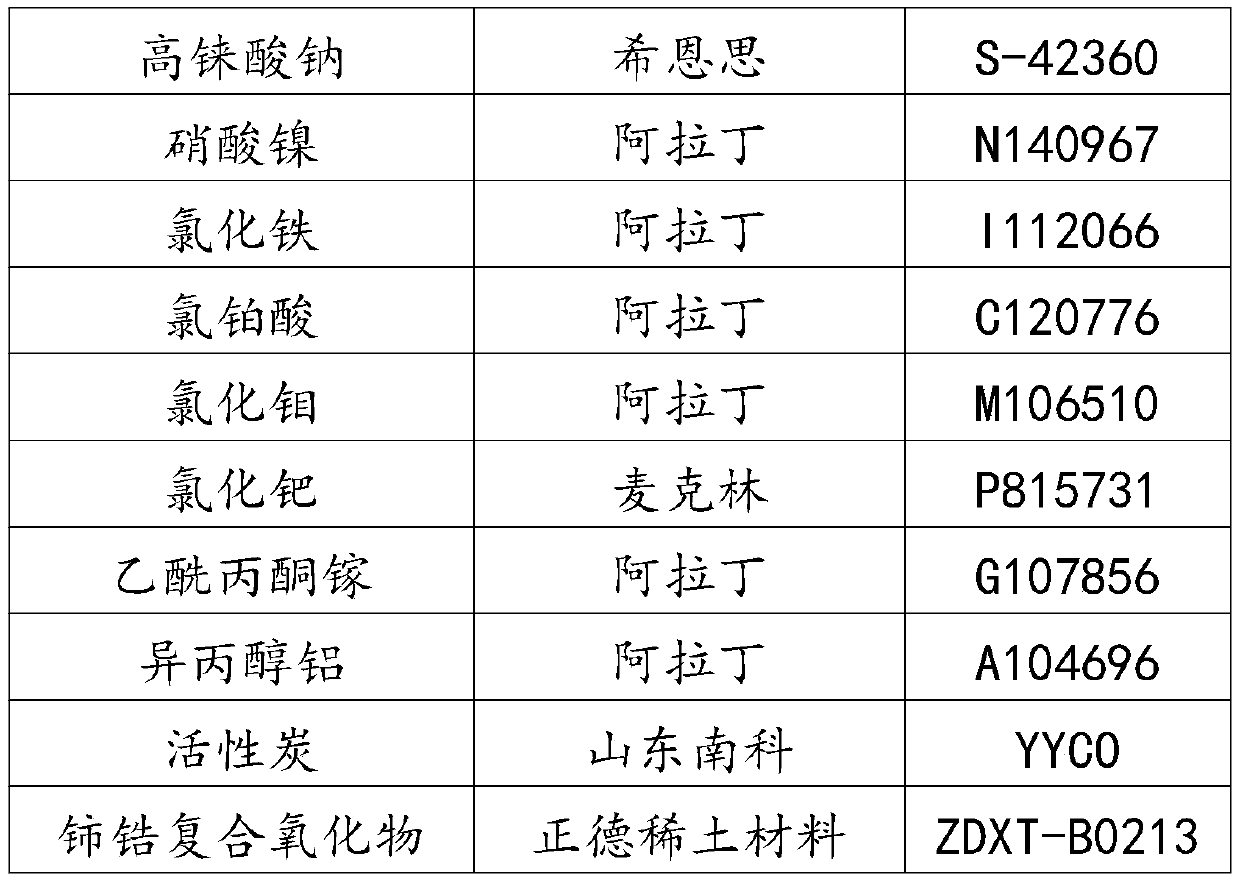

[0053] 1) Preparation of supported copper-rhenium bimetallic catalyst

[0054] Dissolve 135.41g of copper nitrate, 77.73g of perrhenic acid, 5.41g of chloroplatinic acid, and 5.51g of magnesium nitrate in 2kg of deionized water to prepare a mixed saline solution, and disperse 300g of activated carbon powder evenly in the above mixed saline solution to prepare slurry A;

[0055] Dissolve sodium carbonate in water to form a 20wt% sodium carbonate solution, which is the alkaline precipitant B, heat the slurry A and the alkaline precipitant B to 60°C, and slowly add the alkaline precipitant B to the slurry A During the precipitation process, the reaction temperature was controlled at 60°C, and the pH of the system was 7.5; after all the alkaline precipitant B was added dropwise, the slurry was obtained after aging at 70°C for 3 hours;

[0056] The slurry was filtered, washed with deionized water, dried at 110°C for 12h, and roasted at 350°C for 3h, crushed and pressed into a 5*5m...

Embodiment 2

[0062] 1) Preparation of supported copper-rhenium bimetallic catalyst

[0063] Dissolve 173g of copper nitrate, 57.93g of perrhenic acid, 58.26g of cobalt nitrate, and 8.78g of calcium nitrate in 2kg of deionized water to prepare a mixed saline solution, and disperse 300g of carbon nanotube powder evenly in the above mixed saline solution to prepare slurry A;

[0064] Dissolving sodium bicarbonate in water to form a 20wt% sodium bicarbonate solution is the alkaline precipitant B, respectively heating the slurry A and the alkaline precipitant B to 70°C, and slowly adding the alkaline precipitant B to In the slurry A, control the reaction temperature of the precipitation process to 70°C, and the pH of the system to be 7.0; after the alkaline precipitant B is completely added dropwise, the slurry is obtained after aging at 70°C for 3 hours;

[0065] The slurry was filtered, washed with deionized water, dried at 100°C for 12h, and roasted at 290°C for 3h, crushed and pressed into...

Embodiment 3

[0071] 1) Preparation of supported copper-rhenium bimetallic catalyst

[0072] Dissolve 200.53g of copper chloride, 35.06g of ammonium perrhenate, 24.38g of ferric chloride, and 10.23g of barium nitrate in 2kg of deionized water to prepare a mixed saline solution, and disperse 300g of silicon carbide powder evenly in the above mixed saline solution , prepared into slurry A;

[0073] Dissolve ammonium bicarbonate in water to form a 20wt% ammonium bicarbonate solution, which is the alkaline precipitant B. Heat the slurry A and alkaline precipitant B to 60°C respectively, and slowly add the lye B to the slurry A During the precipitation process, the reaction temperature was controlled at 60°C and the pH of the system was 8.0; after all the sodium carbonate solution was added dropwise, the slurry was obtained after aging at 70°C for 3 hours;

[0074] The slurry was then filtered, washed with deionized water, dried at 120°C for 8h, and roasted at 450°C for 5h, crushed and pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com