A kind of low-carbon alkane dehydrogenation catalyst and its preparation method and application

A low-carbon alkane and catalyst technology, which is applied in the field of low-carbon alkane chemical utilization, can solve the problems of high price of Pt-based catalyst, low olefin selectivity, and high single-pass conversion rate, and achieves high alkane single-pass conversion rate, simple method and raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

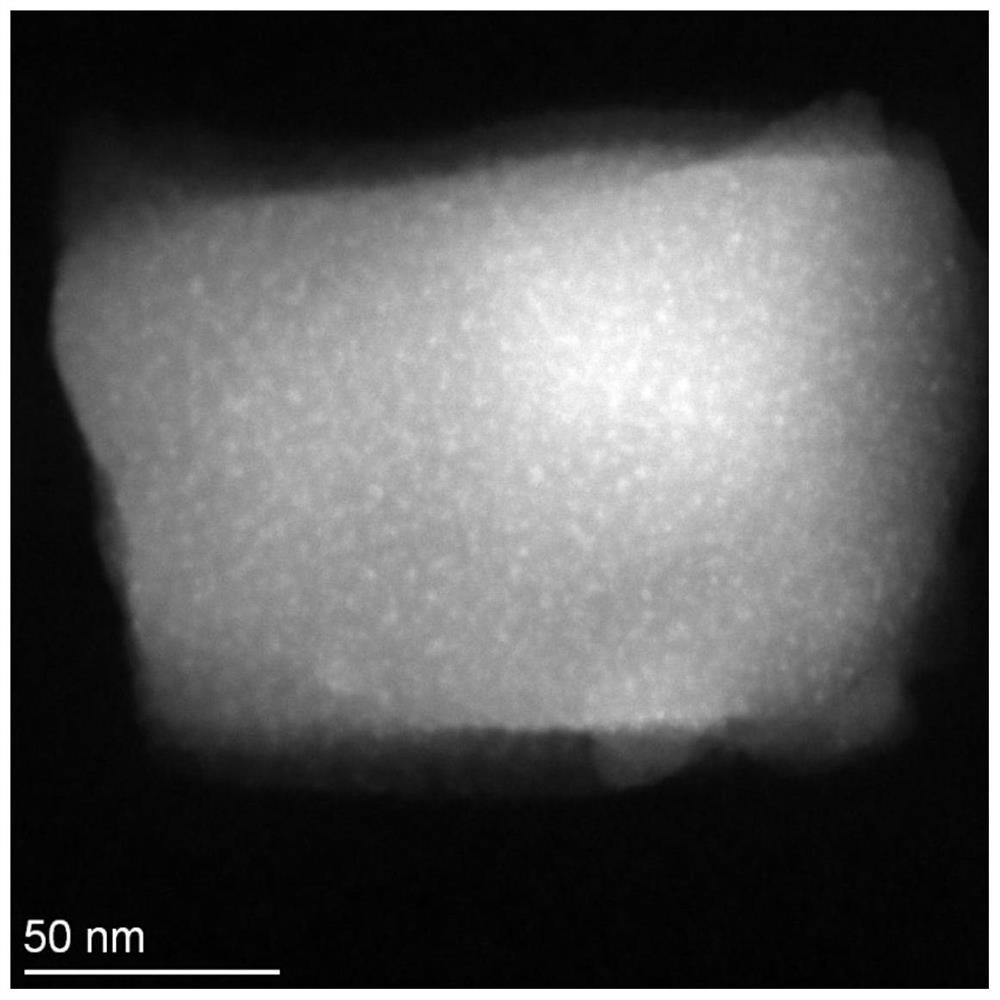

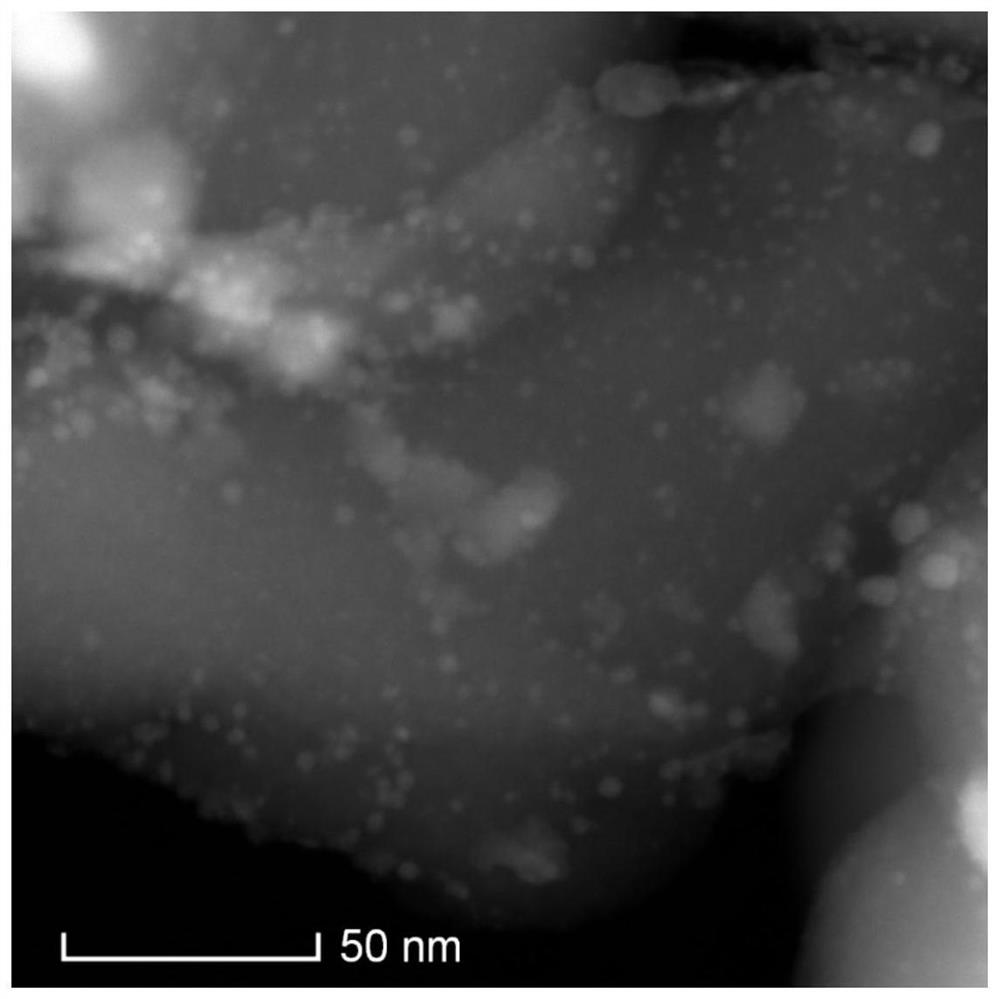

Image

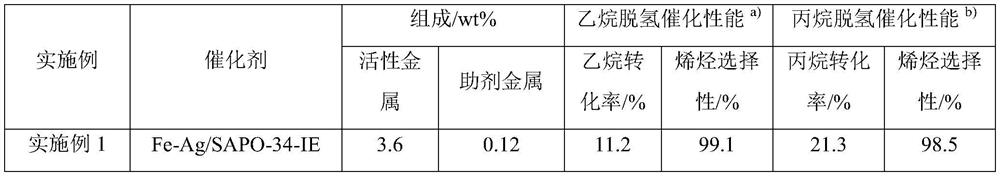

Examples

Embodiment 1

[0039] (1) Weigh 100g SAPO-34 molecular sieve (silicon-aluminum ratio is 0.5), put it into 10mol / L nitric acid solution, stir at 80°C for 12 hours, then filter and fully wash with deionized water until the pH of the filtrate is 7.0; then the washed solid sample was dried in an oven at 100°C for 5 hours, and placed in a muffle furnace for 5 hours at 500°C;

[0040] (2) Take 6 samples of 10.0 g each of the samples treated in step (1), and put them into Co(NO 3 ) 2 , Ni(NO 3 ) 2 , FeCl 2 , Pd(NO 3 ) 2 , Ru(NO 3 ) 3 and RhCl 3 Perform ion exchange in the solution, the concentration of the above solutions is 1.0mol / L, the temperature of ion exchange is 90°C, the time is 15 hours, and the pH value of the solution is 6.9-7.1;

[0041] (3) After ion exchange, use a circulating water vacuum pump (SGB-III) to carry out vacuum filtration (0.01MPa), and fully wash with deionized water until the pH value of the filtrate is 7.0; then wash the solid sample in an oven for 100 ℃ drying...

Embodiment 2

[0046] (1) Weigh 100g of 4A molecular sieve, put it into 10mol / L nitric acid solution, stir and treat it at 80°C for 12 hours, then filter and wash fully with deionized water until the pH value of the filtrate is 7.0; then wash the solid The sample was dried in an oven at 100°C for 5 hours, and placed in a muffle furnace at 500°C for 5 hours;

[0047] (2) Take 6 samples of 10.0 g each of the samples treated in step (1), and put them into Co(NO 3 ) 2 、NiSO 4 , FeCl 2 , Pd(NO 3 ) 2 , Ru(NO 3 ) 3 and RhCl 3 Perform ion exchange in the solution, the concentration of the above solutions is 1.0mol / L, the temperature of ion exchange is 90°C, the time is 15 hours, and the pH value of the solution is 6.9-7.1;

[0048] (3) step (3) is identical with step (3) in embodiment 1, makes the molecular sieve catalyst containing active metal component;

[0049] (4) The catalyzer in the step (3) adopts impregnation method to impregnate auxiliary agent Mn(NO 3 ) 2 solution, Mn(NO 3 ) ...

Embodiment 3

[0052] Take in embodiment 1 by Ni(NO 3 ) 2 The solution realizes ion exchange, and the molecular sieve catalyst Ni / SAPO-34 sample containing active metal components treated in step (3), the solution impregnated in step (4) is replaced by Cu(NO 3 ) 2 solution and Mg(NO 3 ) 2 solution, and the rest of the processes were the same to prepare catalysts Ni-Cu / SAPO-34-IE and Ni-Mg / SAPO-34-IE.

[0053] The contents of active components and promoter metals in the prepared catalysts analyzed by ICP are shown in Table 1. As can be seen from the data in Table 1, the impregnated solutions were replaced by Cu(NO 3 ) 2 solution and Mg(NO 3 ) 2 solution, it can also effectively dope additive metals Cu and Mg, the content of Cu in the catalyst Ni-Cu / SAPO-34-IE is 0.17wt%, and the content of Mg in the catalyst Ni-Mg / SAPO-34-IE is 0.19 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com