Preparation method of ultrafine copper powder for conductive paste

A technology of ultra-fine copper powder and conductive paste, applied in coating and other directions, can solve the problems of copper powder sintering agglomeration, copper powder tap density and low crystallinity, etc., to prevent sintering agglomeration, good oxidation resistance, high dispersive effect

Inactive Publication Date: 2010-12-01

CENT SOUTH UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

First of all, in the process of hydrogen reduction of copper oxide, a large number of oxygen vacancies are generated due to the reaction of oxygen in the oxide with hydrogen and the water generated by their reaction escapes in gaseous form and leaves a large number of pores in the copper powder particles. As a result, the tap density and crystallinity of the copper powder are very low; secondly, during the high-temperature hydrogen reduction process, the prepared copper powder is prone to sintering and agglomeration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

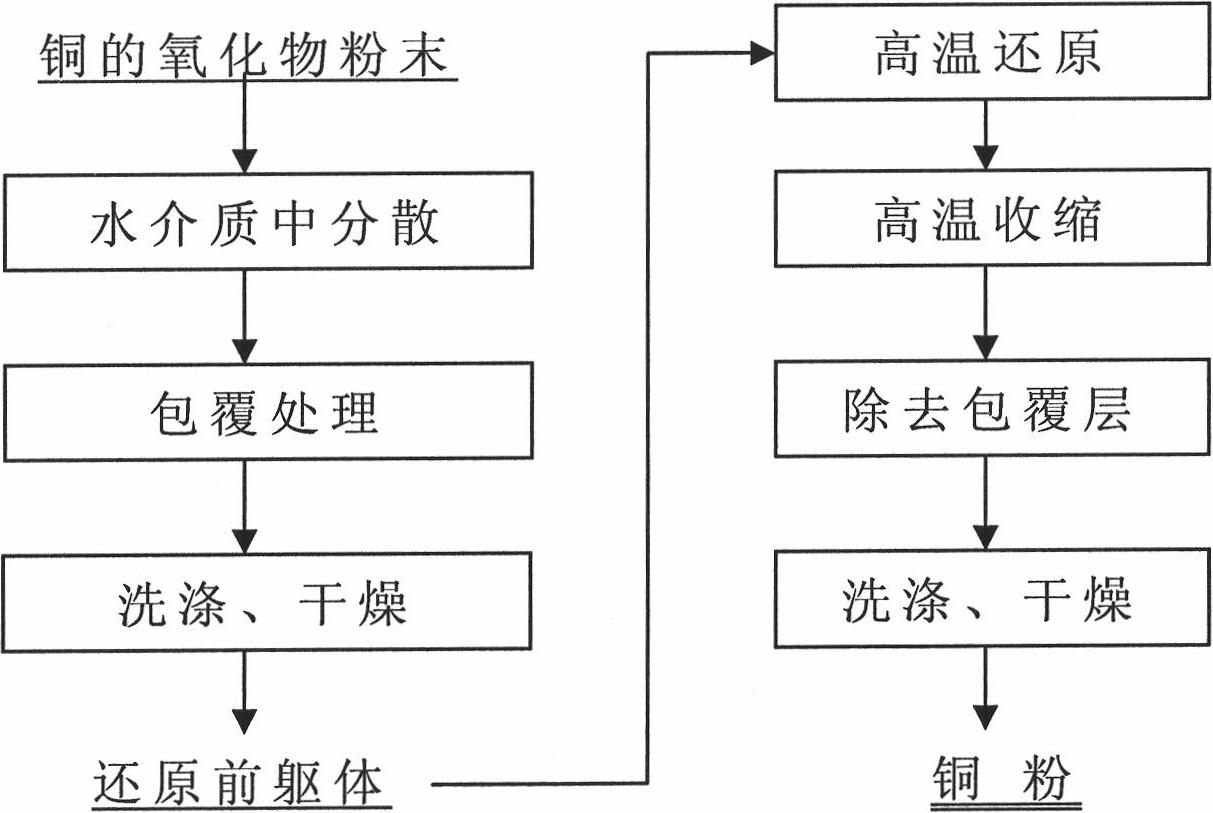

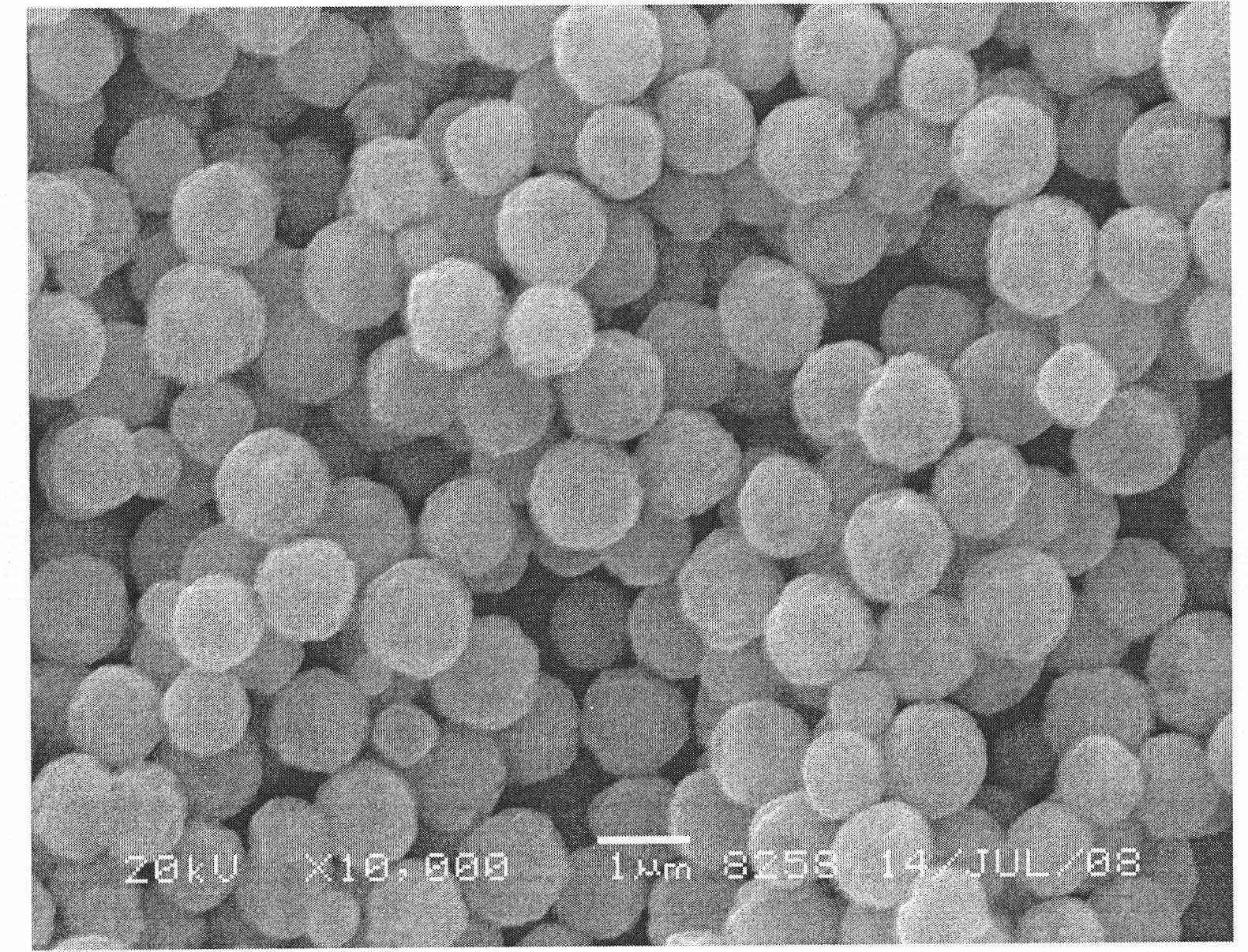

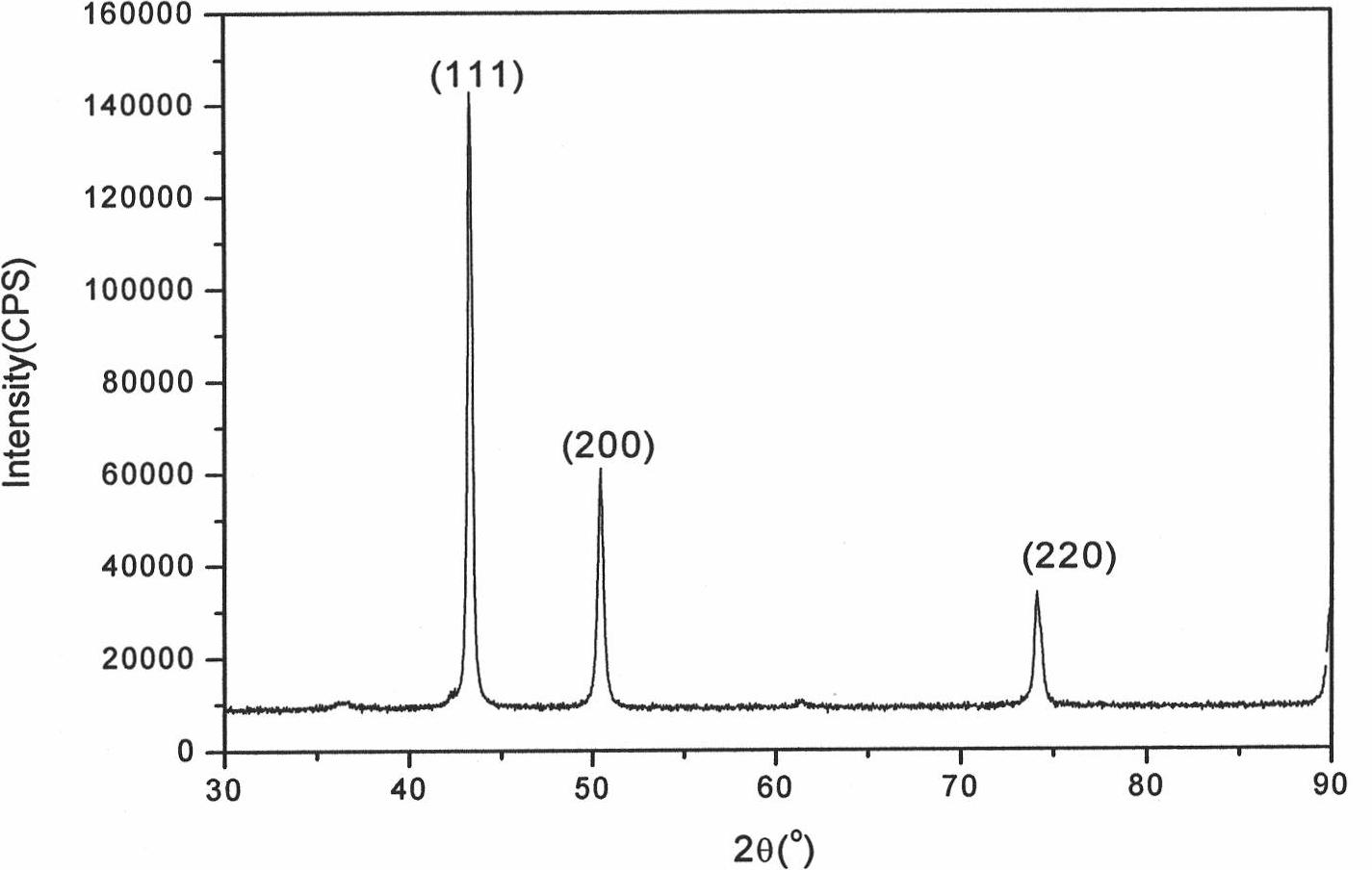

Abstract

The invention discloses a preparation method of ultrafine copper powder for conductive paste. The preparation method comprises the following steps: firstly, coating copper oxide with a compound, reducing the coated copper oxide at high temperature to prepare copper powder, and finally densifying the obtained copper powder at high temperature. The preparation method overcomes preparation cost defect and product performance defect of preparing the copper powder by a gas-phase method and a liquid-phase reduction method, and help produce the ultrafine copper powder which has controllable grain size, good dispersibility, high density and mature crystal form, and meet production requirements for electrodes of multilayer ceramic capacitors. The preparation method has simple equipment and short process flow, and is applicable to industrialized production of the copper powder.

Description

A kind of preparation method of ultrafine copper powder for conductive paste technical field The invention relates to a method for preparing copper powder, in particular to a method for preparing ultrafine copper powder for conductive paste. Background technique Metal powder is an important basic raw material, which can be directly dispersed and used, or it can be pressed and sintered into a bulk material, and can also be made into a film material, etc. For example, ultra-fine copper powder can be used as high-efficiency catalysts, conductive coatings, raw materials for conductive composite materials, electrode materials, additives, etc. Taking the modern electronics industry as an example, multilayer ceramic capacitors (MLCC for short) in the modern electronics industry have become mainstream products in the capacitor industry, and are widely used in communications, computers and consumer electronics products. One of the main development directions of MLCC is the base m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F9/22B22F1/02B22F9/20

Inventor 周康根王岳俊曹艳蒋志刚

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com