Monatomic catalyst for preparing synthesis gas by methane dry reforming as well as preparation method and application of monatomic catalyst

A methane dry reforming and catalyst technology, applied in the field of catalysis, can solve the problems of easy deactivation of catalysts, side reactions of carbon deposition, unsustainable production, etc., and achieve the effects of improving catalytic stability, preventing sintering and agglomeration, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

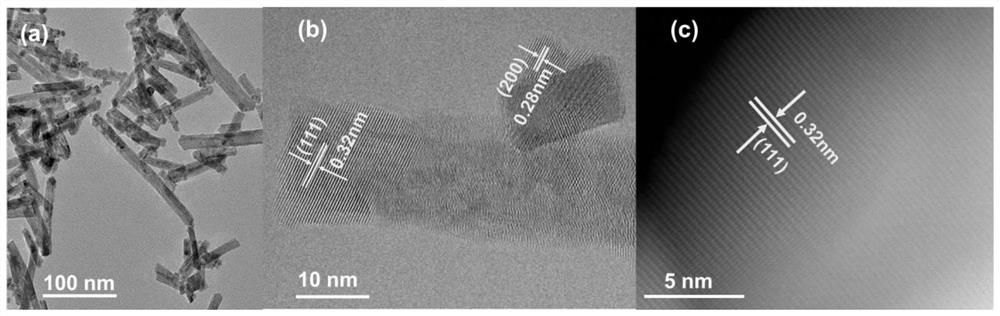

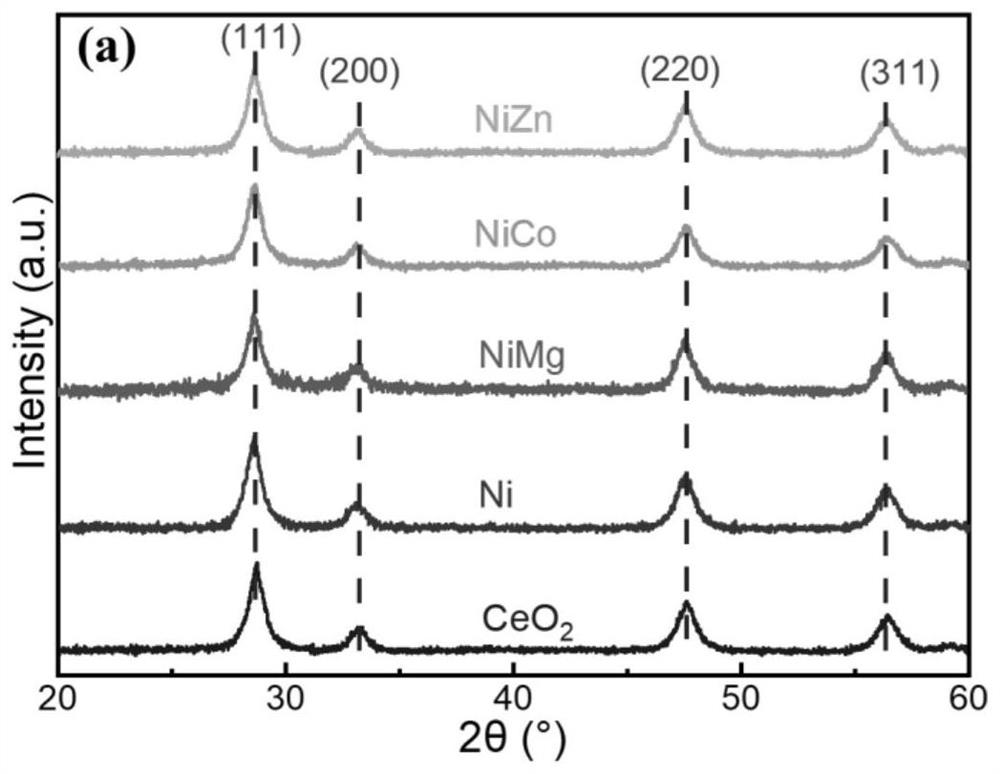

[0030] A single-atom catalyst for preparing synthesis gas by dry reforming of methane, including active component metal Ni, metal promoter Mg, carrier CeO 2 , metal Ni and metal Mg supported on CeO 2 superior.

[0031] A preparation method for a single-atom catalyst for methane dry reforming, comprising the following steps:

[0032] (1), take by weighing 16.8g sodium hydroxide and add 70mL pure water, stir evenly with glass rod, obtain the sodium hydroxide solution of 6mol / L; Weigh 1.51337g cerium nitrate hexahydrate, 0.074g nickel nitrate hexahydrate, 0.079 g magnesium nitrate hexahydrate was dissolved in 10mL water to obtain a precursor nitrate solution; add the precursor nitrate solution dropwise to the vigorously stirred sodium hydroxide solution, and continue stirring for 30 minutes after all the addition was completed, and a suspension was obtained after precipitation liquid;

[0033] (2) Transfer all the suspension obtained in step (1) to a hydrothermal kettle, and c...

Embodiment 2

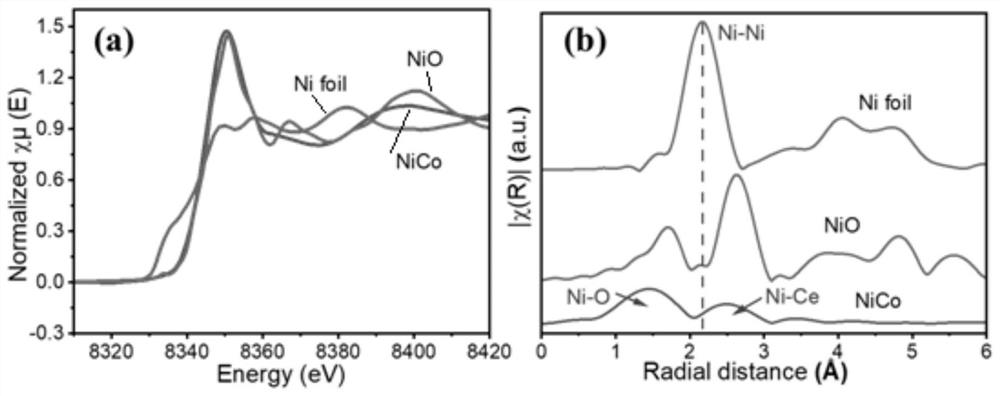

[0035] A single-atom catalyst for dry reforming of methane to prepare synthesis gas, including active component metal Ni, metal promoter Co, and carrier CeO 2 , metal Ni and metal Co supported on CeO 2 superior.

[0036] A preparation method for a single-atom catalyst for methane dry reforming, comprising the following steps:

[0037] (1), take by weighing 16.8g sodium hydroxide and add 70mL pure water, stir evenly with glass rod, obtain the sodium hydroxide solution of 6mol / L; Weigh 1.51337g cerium nitrate hexahydrate, 0.074g nickel nitrate hexahydrate, 0.037 g cobalt nitrate hexahydrate was dissolved in 10mL water to obtain a precursor nitrate solution; add the precursor nitrate solution dropwise to the vigorously stirred sodium hydroxide solution, and continue stirring for 30 minutes after all the addition was completed, and a suspension was obtained after precipitation liquid;

[0038] (2), transfer all the suspension obtained in step (1) to a hydrothermal kettle, and c...

Embodiment 3

[0040] A single-atom catalyst for preparing synthesis gas by dry reforming of methane, including active component metal Ni, metal promoter Zn, and carrier CeO 2 , metal Ni, metal Zn supported on CeO 2 superior.

[0041] A preparation method for a single-atom catalyst for methane dry reforming, comprising the following steps:

[0042](1), take by weighing 16.8g sodium hydroxide and add 70mL pure water, stir evenly with glass rod, obtain the sodium hydroxide solution of 6mol / L; Weigh 1.51337g cerium nitrate hexahydrate, 0.074g nickel nitrate hexahydrate, 0.034 g zinc nitrate hexahydrate was dissolved in 10mL water to obtain a precursor nitrate solution; add the precursor nitrate solution dropwise to the vigorously stirred sodium hydroxide solution, and continue stirring for 30 minutes after all the addition was completed, and a suspension was obtained after precipitation liquid;

[0043] (2) Transfer all the suspension obtained in step (1) to a hydrothermal kettle, and conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com