Catalyst for aromatization of waste edible oil and production method and application of catalyst for aromatization of waste edible oil

A technology for waste edible oil and catalyst, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low activity, selectivity and stability of aromatization catalysts, and achieve the goal of inhibiting carbon deposition, Prevent agglomeration, sintering and loss, and ensure the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

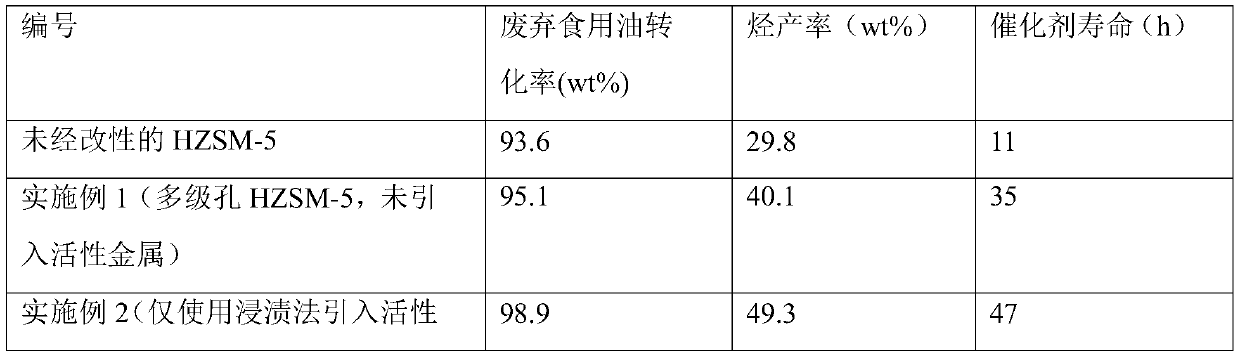

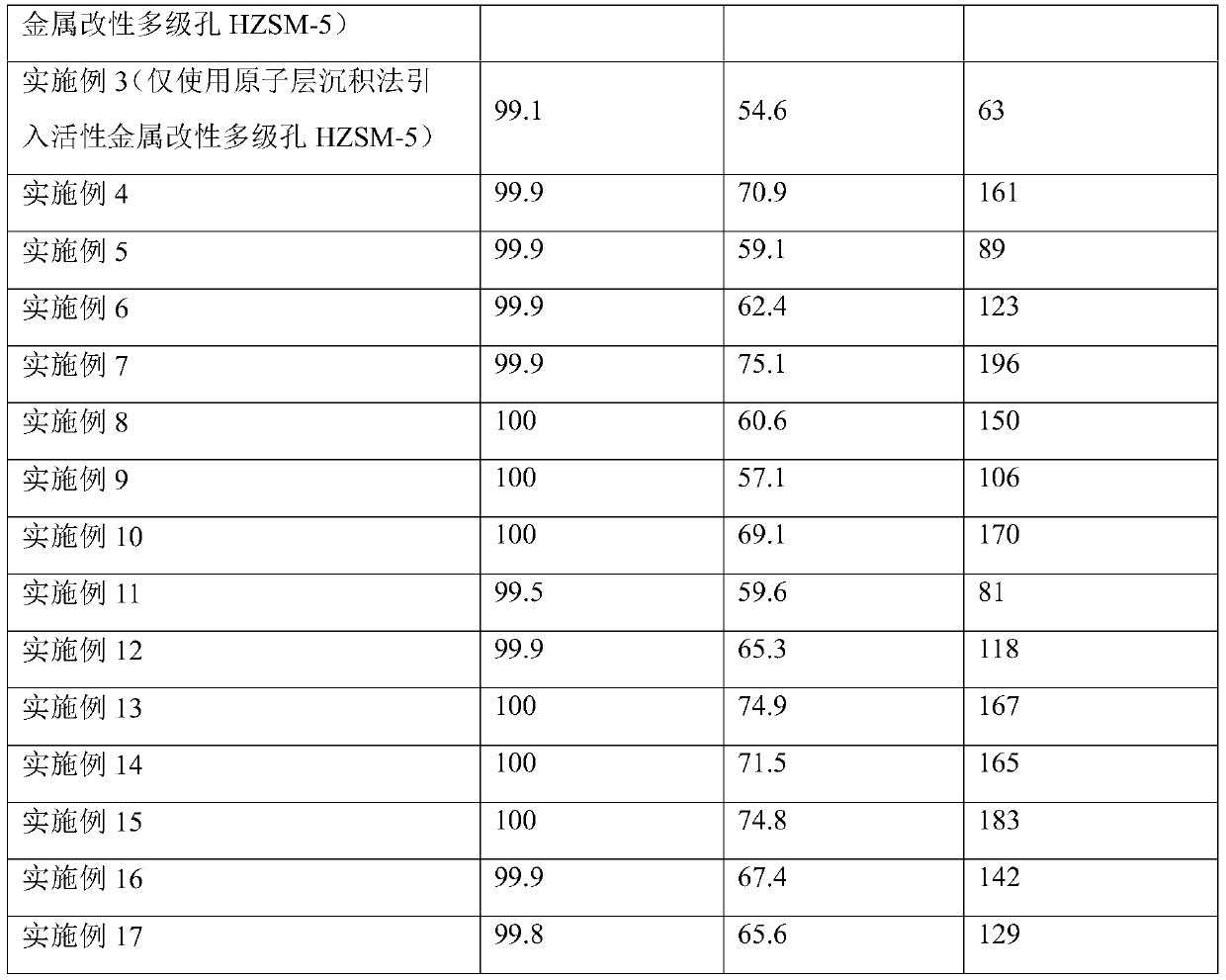

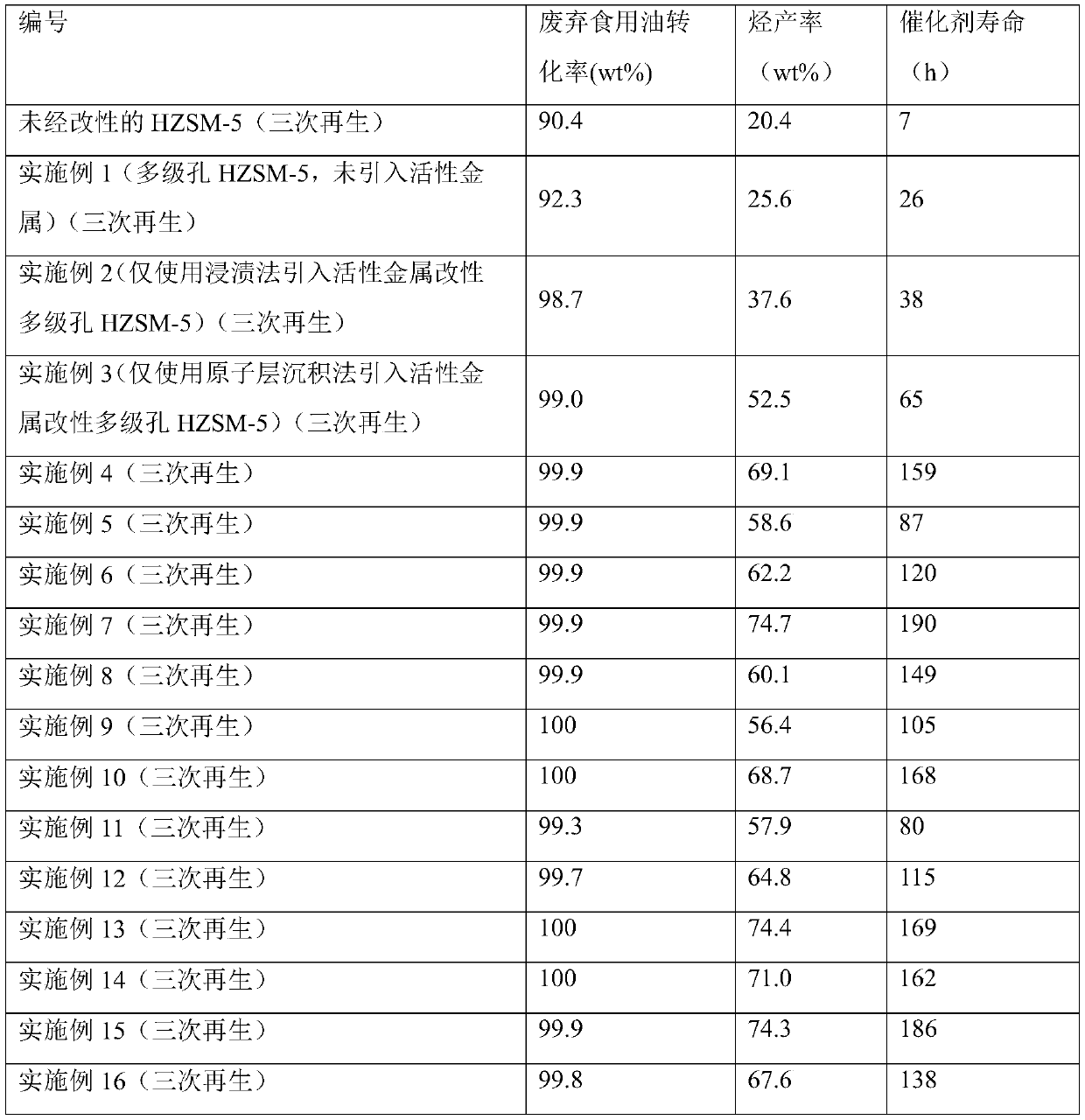

Examples

Embodiment 1

[0027] Embodiment 1: prepare hierarchical porous HZSM-5 catalyst (do not introduce active metal):

[0028] Dissolve 10g of ZSM-5 in 300mL of NaOH solution with a concentration of 0.30mol / L, stir and mix thoroughly, then place it in a water bath at 80°C for 2h, then cool the suspension to room temperature, filter and wash until neutral . Then, the washed molecular sieves were exchanged three times with 0.8 mol / L ammonium nitrate solution at 75°C for 12 hours each time. After the exchange, the obtained suspension was filtered and washed, and then the obtained solid sample was dried at 120°C for 10 hours, and then calcined at 550°C for 5 hours, and finally the solid powder was obtained as hierarchically porous HZSM-5.

Embodiment 2

[0029] Example 2: Preparation of Hierarchical Porous SnO 2 / HZSM-5 catalyst (only the impregnation method was used to introduce the active metal into the hierarchically porous HZSM-5, no ALD modification):

[0030] 1) Dissolve 10g of ZSM-5 in 300mL of NaOH solution with a concentration of 0.30mol / L, stir and mix thoroughly, then place in a water bath at 80°C for 2h, then cool the suspension to room temperature, filter and wash until neutral. Then, the washed molecular sieves were exchanged three times with 0.8 mol / L ammonium nitrate solution at 75°C for 12 hours each time. After the exchange, the obtained suspension was filtered and washed, and then the obtained solid sample was dried at 120° C. for 10 h, and then calcined at 550° C. for 5 h to finally obtain a solid powder.

[0031] 2) Add the solid powder obtained in step 1) to SnCl 4 In the aqueous solution, a suspended material is formed, which is impregnated for 16 hours under stirring conditions. After the impregnatio...

Embodiment 3

[0032] Example 3: Preparation of Hierarchical Porous HZSM-5@ZnO@SiO 2 Catalyst (active metal introduced into hierarchically porous HZSM-5 using atomic layer deposition only, not modified by impregnation):

[0033] 1) Same as embodiment 2 step 1).

[0034] 2) The hierarchically porous HZSM-5 obtained in step 1) is placed in the flow chamber of the ALD reaction, and the metal source is deposited on the hierarchically porous HZSM-5 by atomic layer deposition. The metal source used is diethyl zinc, The deposition temperature was 180°C, and the number of deposition cycles was 30 to obtain the HZSM-5@ZnO catalyst.

[0035] 3) The HZSM-5@ZnO catalyst obtained in step 2) is placed in the flow chamber of the ALD reaction, and the SiO 2 The film is deposited on the pores and acidic sites on the outer surface of HZSM-5, the deposition temperature is 180°C, and the number of deposition cycles is 30. The deposited sample is fired at 550°C for 5 hours to obtain HZSM-5@ZnO@SiO 2 catalyst....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com