Carbon-based Fe/S/N co-doped oxygen reduction catalyst as well as preparation method and application thereof

A catalyst and co-doping technology, applied in the preparation/purification of carbon, fuel cell type half-cell and primary cell type half-cell, electrical components, etc., can solve problems such as limited catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

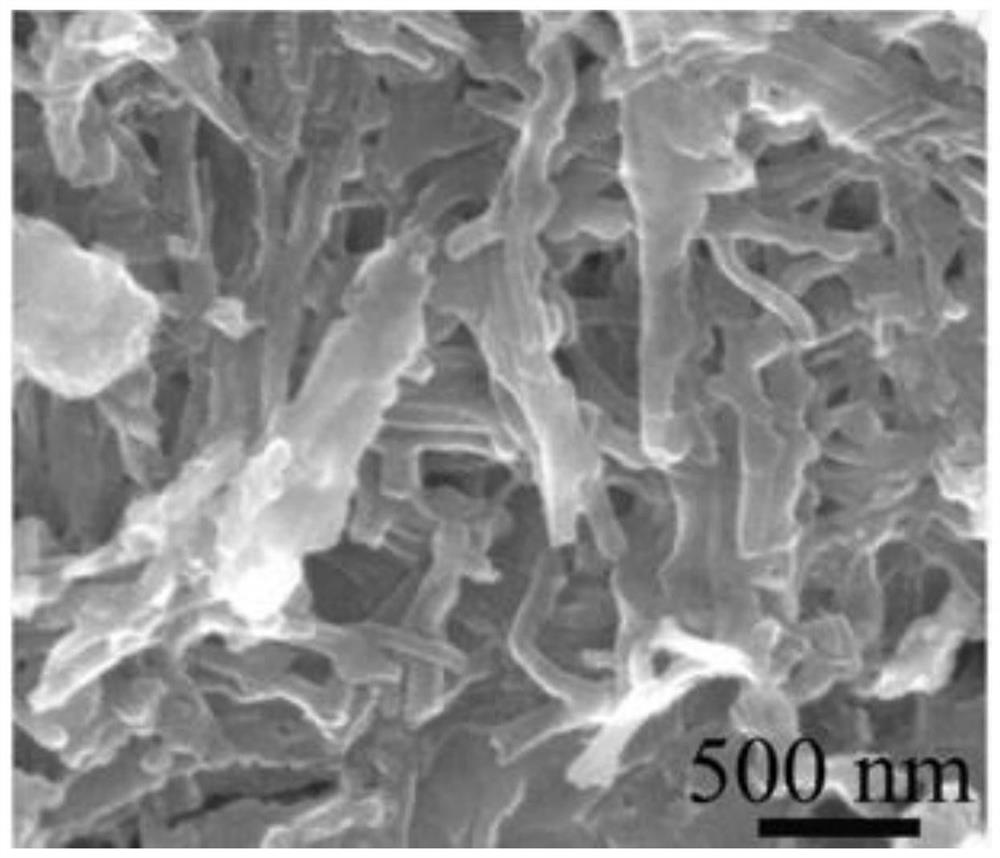

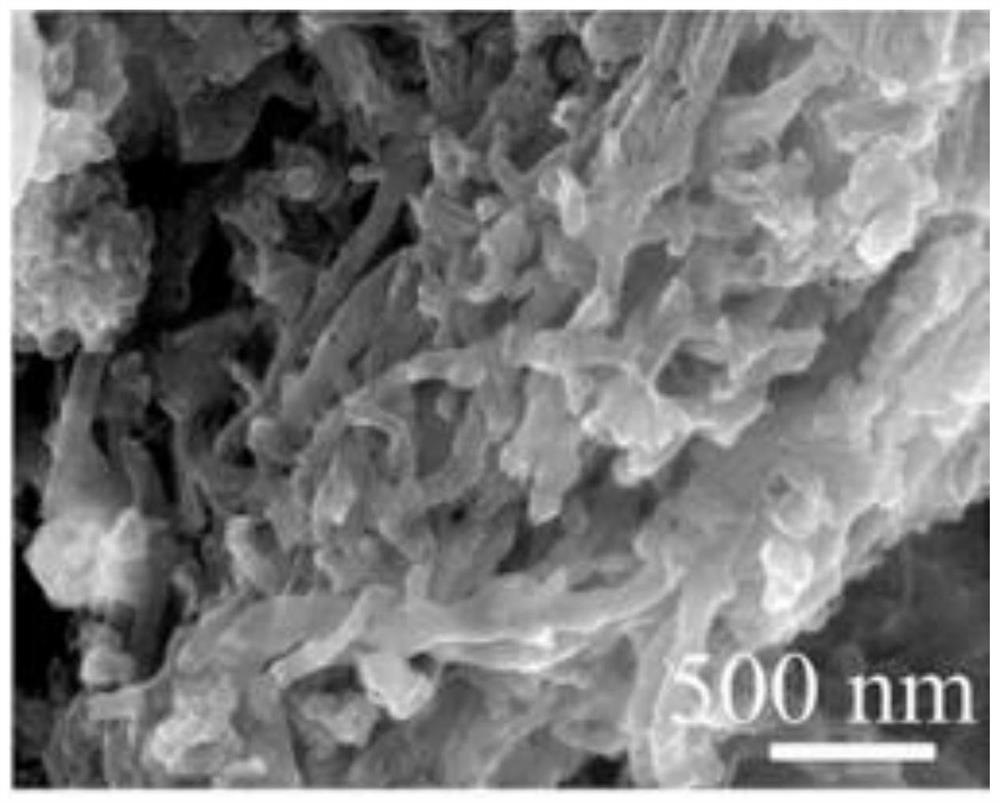

Image

Examples

Embodiment 1

[0052] Preparation of iron porphyrin-based cross-linked microporous polymer: Take 211.2 mg (0.3 mmol) of 5,10,15,20-tetraphenyliron porphyrin and 292.5 mg (1.8 mmol) of anhydrous ferric chloride in a dry in the flask. After the flask was sealed and vacuumed, nitrogen was introduced three times. Then, 160 μL (1.8 mmol) of dimethanol formal and 8 mL of dehydrated dichloroethane were added, and the reaction was stirred and refluxed at 80°C for 27 hours under a nitrogen atmosphere. After the reaction, the solid-liquid mixture was suction-filtered, washed with dichloroethane, methanol, water, and methanol in sequence, and then extracted with methanol in a Soxhlet extractor for 24 hours. After drying, an iron porphyrin-based cross-linked microporous polymer is obtained.

[0053] Preparation of iron porphyrin-based cross-linked microporous polymer doped with polythiophene: take 100 mg of iron porphyrin-based cross-linked micro-porous polymer and 200 mg (2.38 mmol) thiophene in 80 mL...

Embodiment 2

[0058] Preparation of oxygen reduction working electrode: Disperse 5 mg of the above-mentioned synthesized sample in 800 microliters of Nafion isopropanol solution with a volume fraction of 3%, and disperse the material evenly by ultrasonic waves. Take 10 microliters drop by drop in a dry rotating Disc electrode (diameter 5mm), after natural drying, test the electrochemical catalytic performance of the sample.

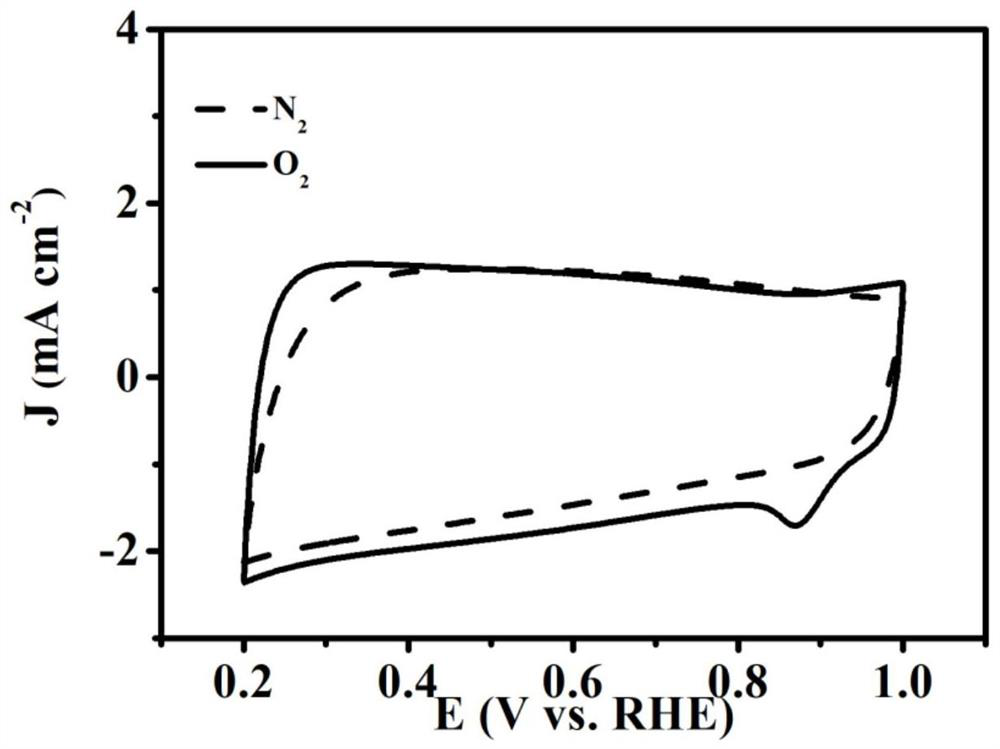

[0059] image 3 It is the cyclic voltammetry curve of the oxygen reduction catalyst obtained in this embodiment, in saturated N 2 Under the 0.1M KOH electrolyte solution, the cyclic voltammogram in the voltage range of 0.2-1.0V is similar to a rectangle, and there is no obvious reduction peak. Relatively speaking, at saturation O 2 Under the 0.1M KOH electrolyte solution, there is an obvious characteristic peak of oxygen reduction reaction (ORR), indicating that this material has significant electrocatalytic activity for oxygen reduction reaction, and its reduction p...

Embodiment 3

[0061] Preparation of air electrode: 5% Nafion solution, ultrapure water and ethanol are mixed according to the volume ratio of 3:30:70 to obtain a mixed solution, and the oxygen reduction catalyst prepared above is ultrasonically dispersed into the mixed solution, and then sprayed on carbon paper or carbon cloth On the electrode, dry to obtain an air electrode, and the loading of the catalyst is 1mg / cm 2 . For comparison, an air electrode was fabricated using the same procedure with 20wt% commercial platinum carbon as a catalyst. A zinc-air fuel cell is formed by using the fabricated air electrode as the cathode, zinc sheet as the anode, and 6M KOH solution as the electrolyte. The open circuit voltage and polarization curve of the battery are obtained by testing at normal temperature and pressure.

[0062] Figure 6 The open circuit voltage of the zinc-air fuel cell produced for this example shows that the open circuit voltage of the single cell is 1.48V, which is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com