High-thermal-stability aluminum oxide/nickel/aluminum oxide sandwich structure catalyst as well as preparation method and application thereof

A sandwich structure, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor activity and thermal stability, achieve carbon deposition inhibition, broad application prospects, high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Will contain 0.169g NiCl 2 ·6H 2 O aqueous solution impregnated in 1.0 g γ-Al 2 o 3 Stand on the carrier overnight, dry in an oven at 100°C, then raise the temperature to 800°C at a rate of 2°C / min, and keep it for 4 hours to prepare Ni / Al 2 o 3 The supported catalyst is named 4NiAl.

Embodiment 2

[0040] With trimethylaluminum (TMA) and water as the reaction source, the deposition temperature was set at 200 °C, and the working pressure of the reaction chamber was maintained at 0.3 The substrate adopts K9 glass and JGSl quartz glass with a diameter of 30mm and a thickness of 2mm. Under this condition, in embodiment 1 gained Ni / Al 2 o 3 Deposition of 40 layers of Al on the surface of the supported catalyst 2 o 3 Thin film, prepared 40-Al 2 o 3 / Ni / Al 2 o 3 Sandwich structure catalyst named as 4NiAl-40ALD catalyst.

Embodiment 3

[0042] With trimethylaluminum (TMA) and water as the reaction source, the deposition temperature was set at 200 °C, and the working pressure of the reaction chamber was maintained at 0.3 The substrate adopts K9 glass and JGSl quartz glass with a diameter of 30mm and a thickness of 2mm. Under this condition, in the Ni / Al obtained in embodiment 1 2 o 3 Deposit 80 layers of Al on the surface of supported catalyst 2 o 3 thin film, prepared 80-Al 2 o 3 / Ni / Al 2 o 3 Sandwich structure catalyst named as 4NiAl-80ALD catalyst.

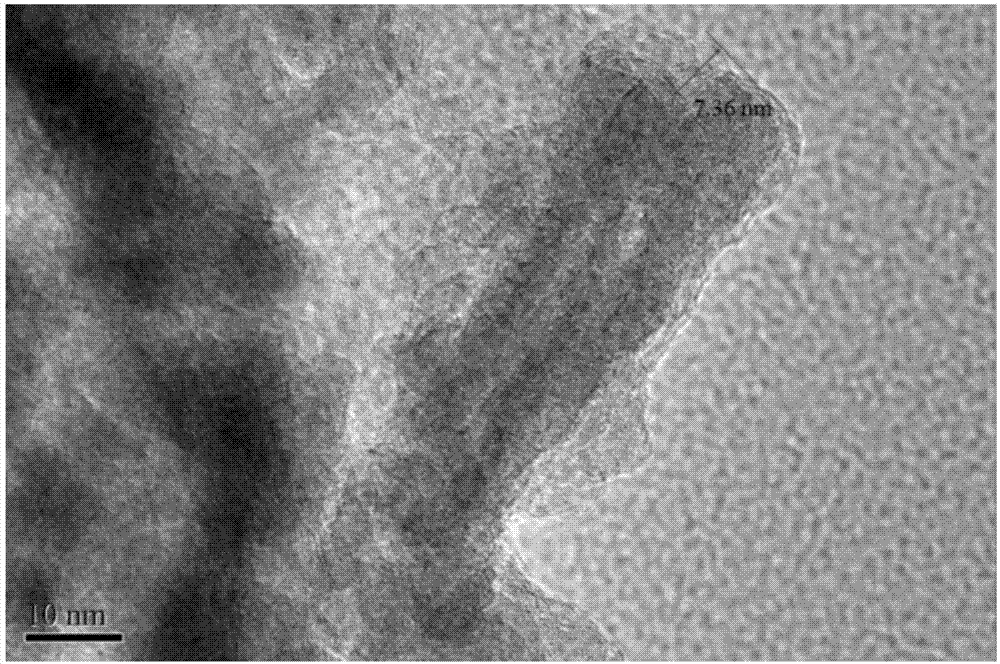

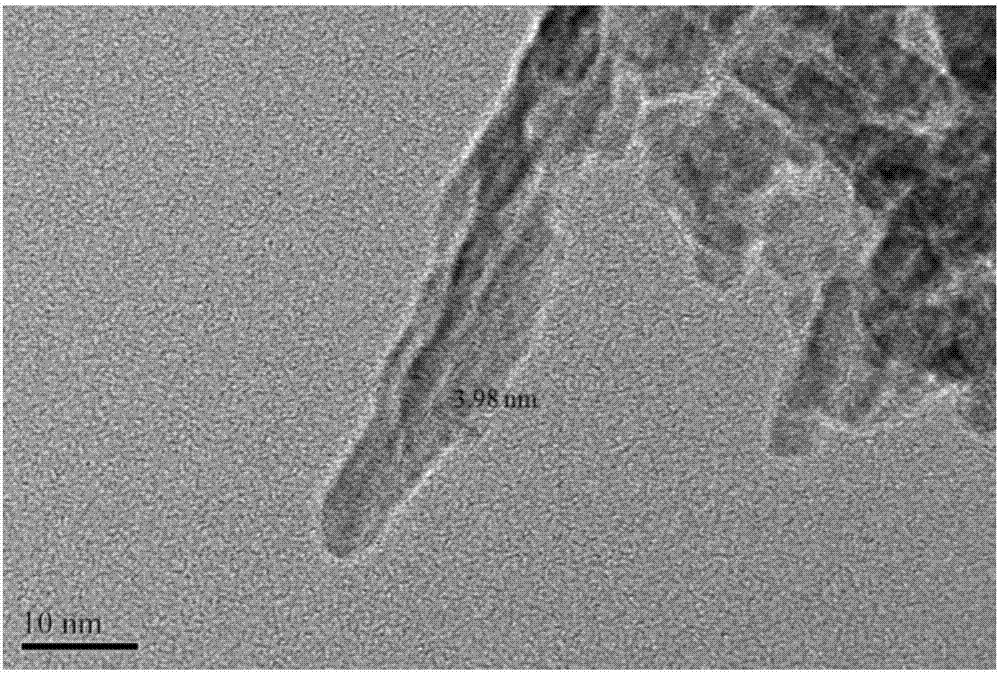

[0043] Depend on figure 1 , 2 Visible, rod-shaped γ-Al 2 o 3 The surface of the carrier is covered with a layer of Al 2 o 3 Thin film, surface covered Al in 4NiAl-40ALD catalyst 2 o 3 The thickness of the film is about 4nm, and the Al covered on the surface of the 4NiAl-80ALD catalyst 2 o 3 The film thickness is about 8nm.

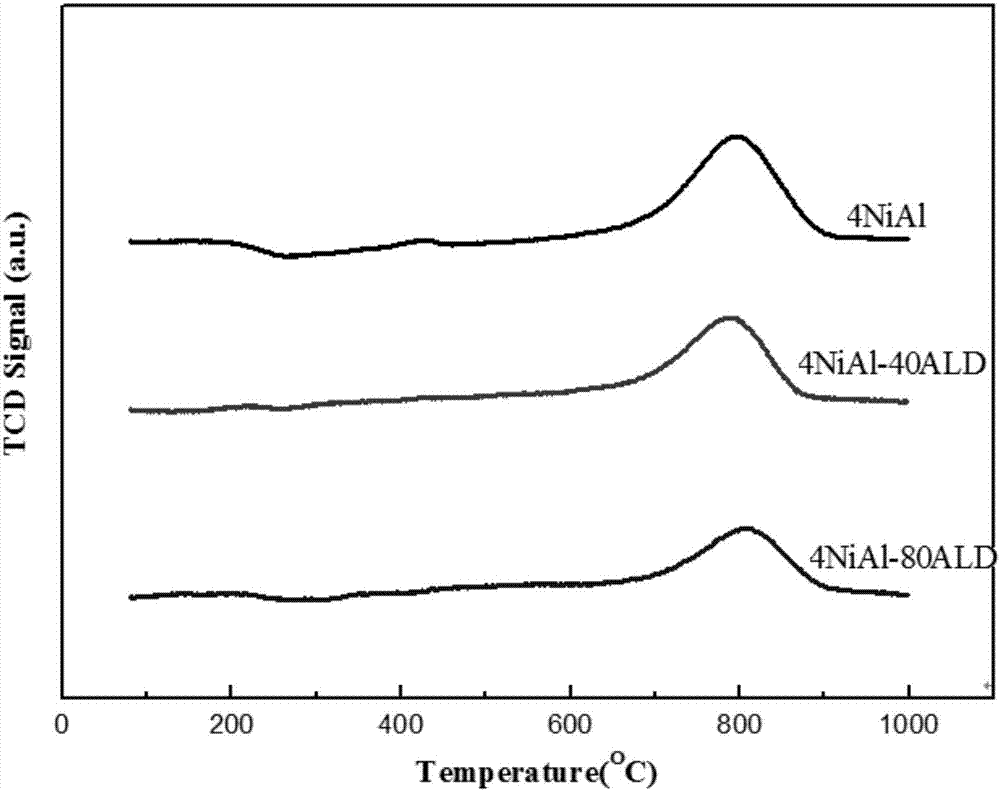

[0044] Depend on image 3 It can be seen from the TPR spectrum that the reduction peak of NiO in 4NiAl-80ALD moves to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com