Method for producing superfine lead-free solder powder

A technology of fine lead-free solder powder and production method, which is applied in the production field of ultra-fine lead-free solder powder, can solve the problems of high oxygen content, insufficient cooling, low powder yield, etc., achieve uniform alloy composition, prevent composition segregation, The effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

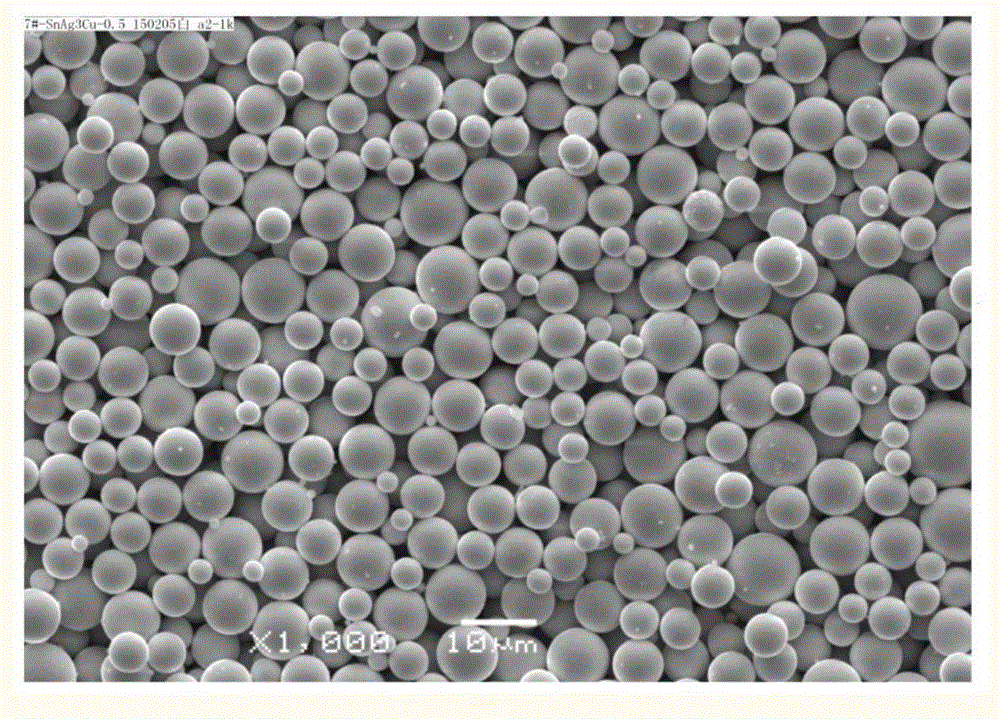

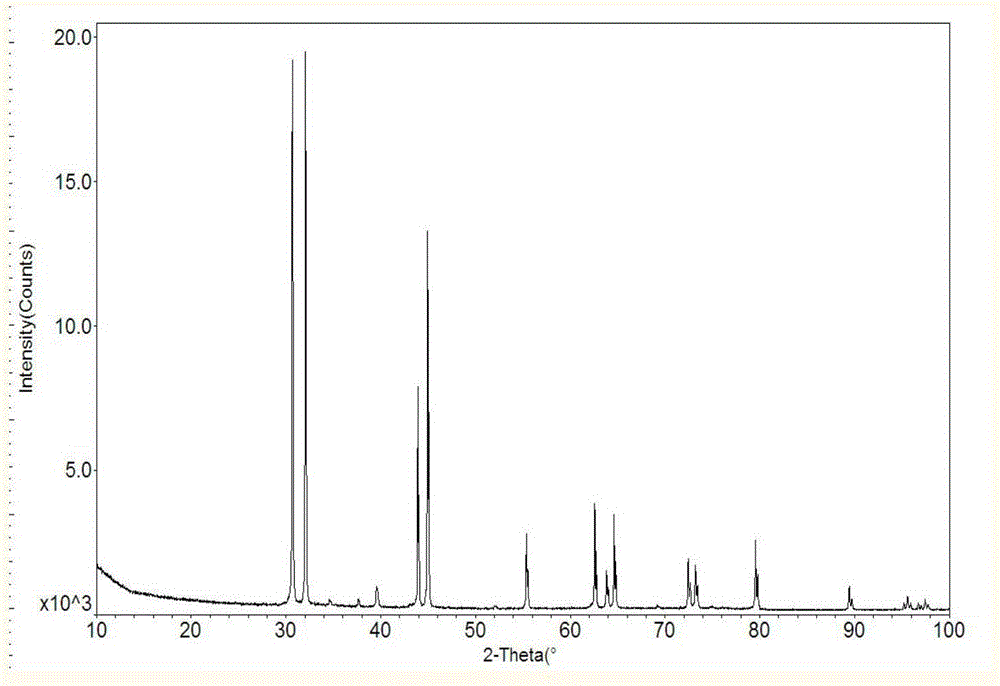

[0024] Embodiment 1, ultrafine Sn 96.5 Ag 3 Cu 0.5 Alloy powder production

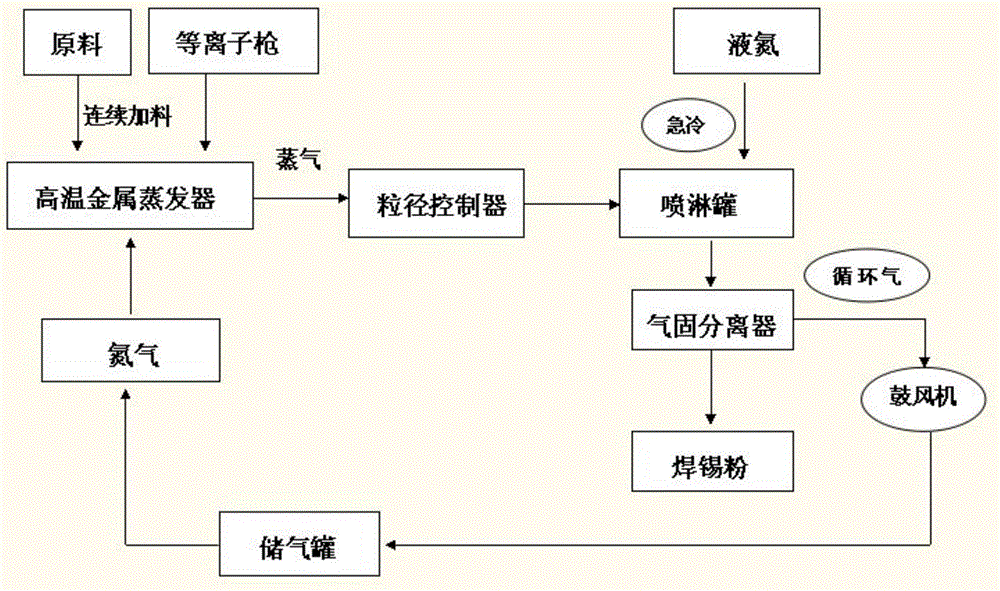

[0025] A certain amount of Sn 96.5 Ag 3 Cu 0.5 Put the alloy raw material into the crucible of the high-temperature metal evaporator, install the plasma generating device, check the air tightness, pump the vacuum, and flush the whole system with nitrogen to make the whole system under an inert gas atmosphere. Control the pressure in the crucible to about 110kPa, and start the plasma generation device, the power of the plasma transfer arc is increased to 25kW, the raw material is melted into alloy liquid, and after 2.5-3 hours of heat preservation, the power of the plasma gun is rapidly increased to 100kW, and the bottom is adjusted so that the air intake is at 25m 3 / h, observe the liquid level in the crucible, start to feed continuously, and the feed rate is 10kg / h. The alloy liquid forms vapor under the action of the plasma transfer arc, and the vapor is transported to the particle controller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com