Prediction of cavity size in the packed bed systems using new correlations and mathematical model

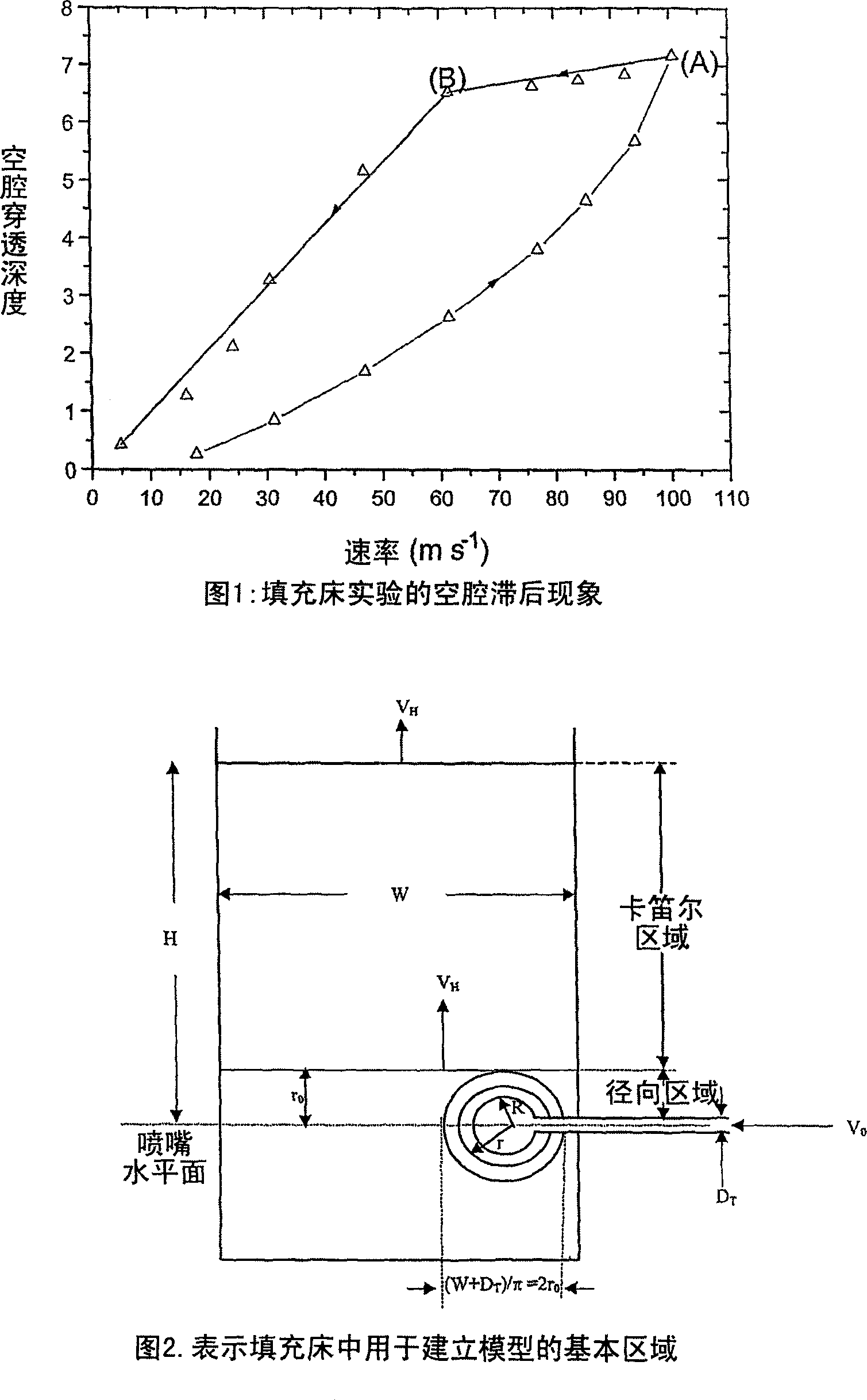

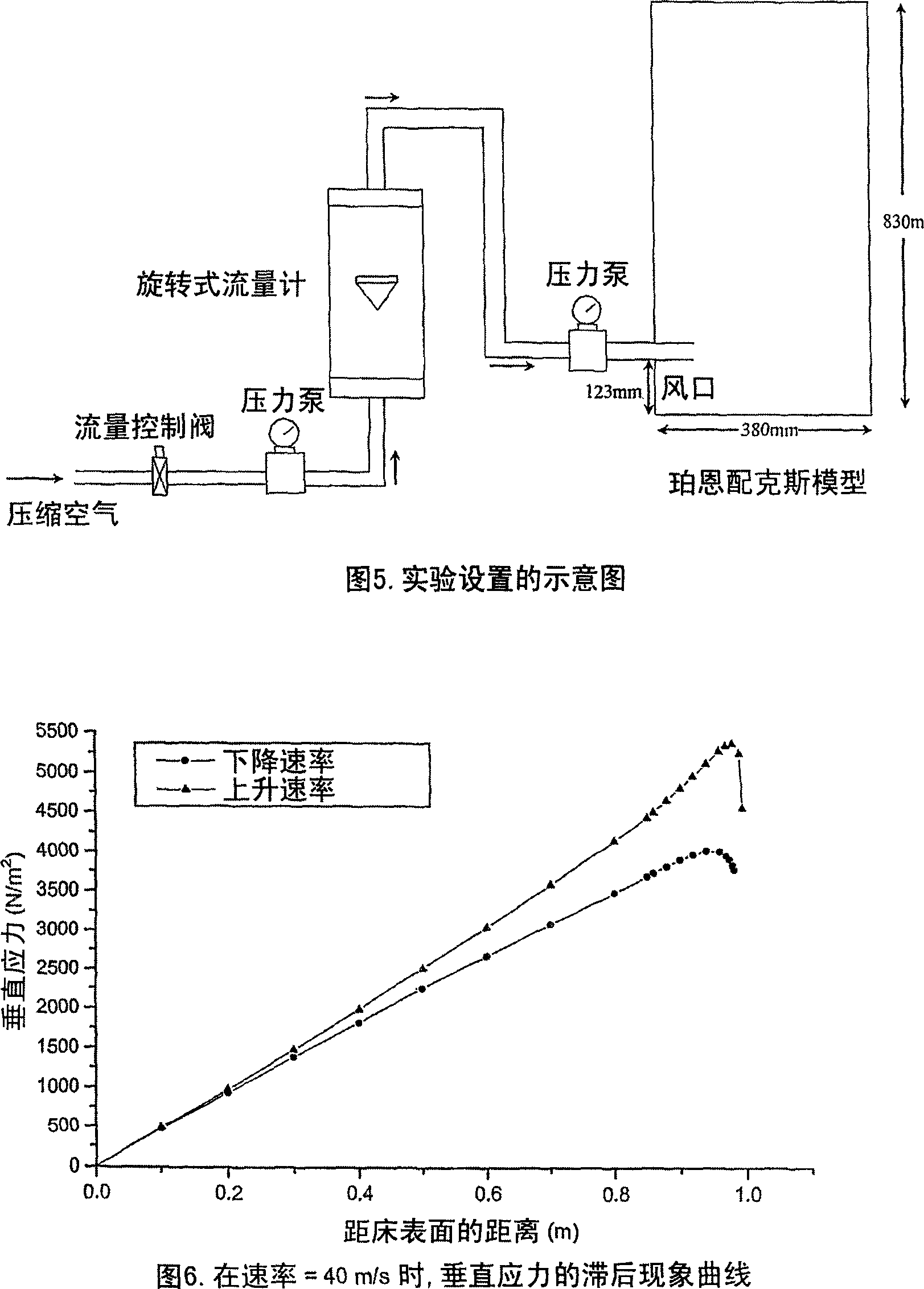

一种相互关系、数学模型的技术,应用在空腔的尺寸领域,能够解决没有预测空腔尺寸、鼓风速率燃烧空窝深度下降、不能显示滞后现象的结果等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

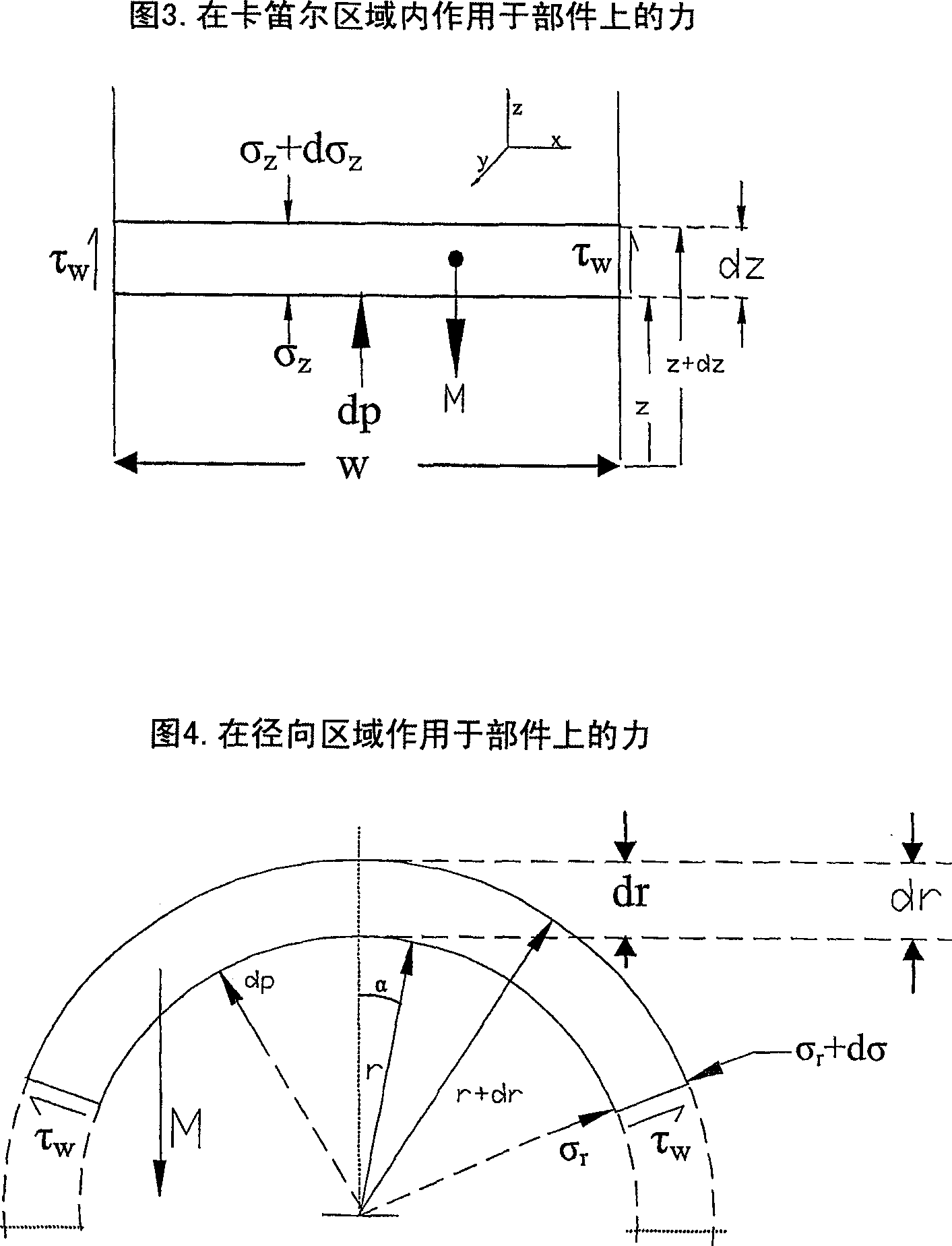

[0019] The present invention provides a computer-based method for determining the size of a cavity in a packed bed system using a correlation or mathematical model, said method comprising the steps of:

[0020] a) obtaining data on the material properties of the packed bed system;

[0021] b) Using the mathematical model that introduces stress / friction force, calculate the cavity radius when the gas velocity rises and the gas velocity decreases, expressed as:

[0022] 2 n R 2 - 2 nHR + prβ v b 2 D T 2 2 π 2 M { ln W 2 π - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com