Smoke purifier

A purifier and fume technology, applied in chemical instruments and methods, waste heat treatment, use of liquid separation agents, etc., can solve the problems of large size, high price, and difficulty in promoting and applying in small and medium-sized enterprises, and achieve good purification effect. Low production cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

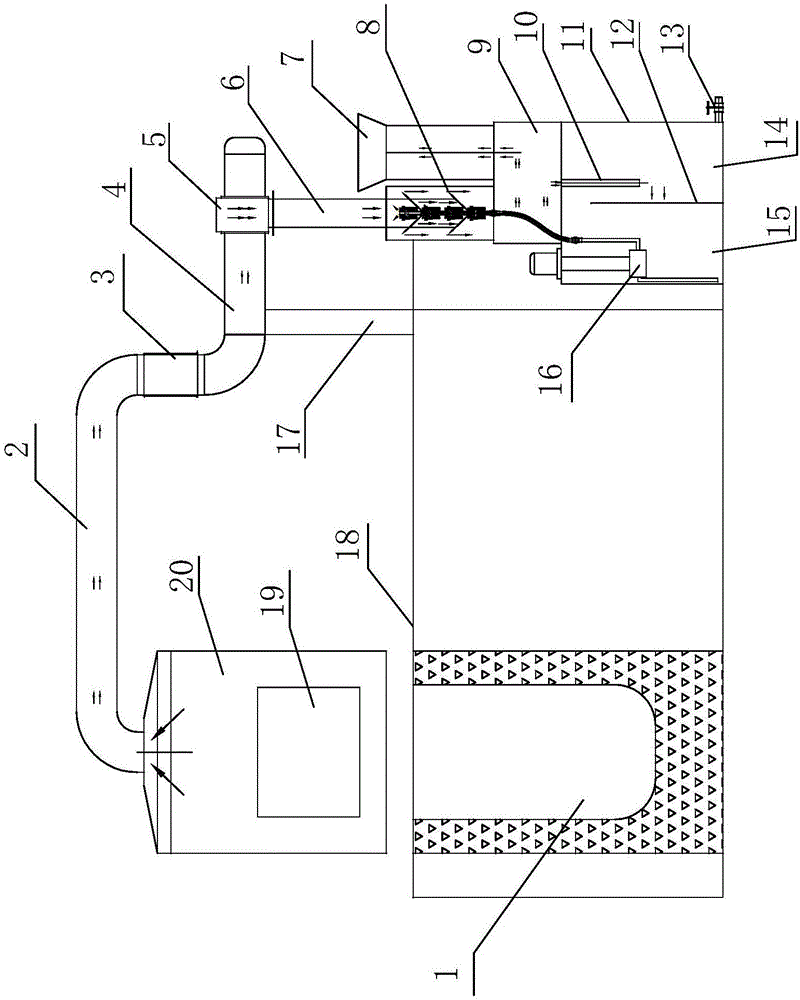

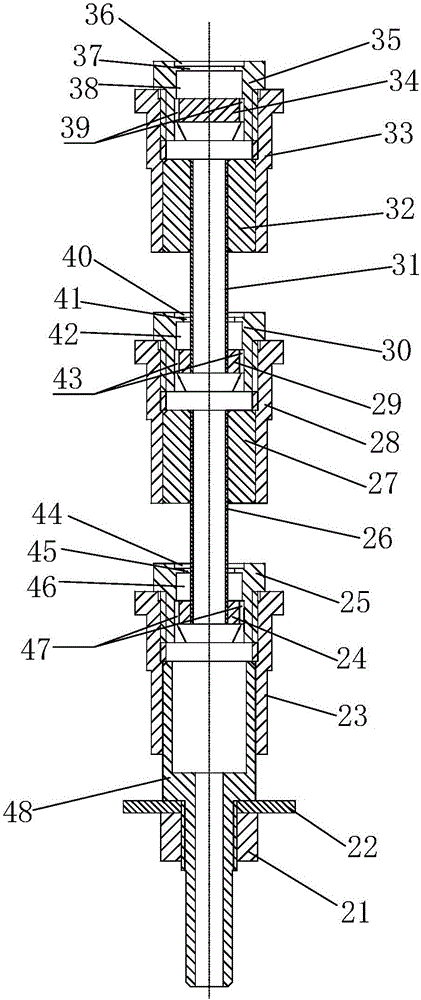

[0016] like figure 1 , figure 2 As shown, the soot purifier of the present invention comprises a fume cover 20 covered on the iron furnace 1, a smoking pipe connected to the fume cover 20, an exhaust fan 5 arranged in the smoking pipe, and an exhaust gas connected to the exhaust fan 5 rear end. Pipe 6, multi-layer atomizer 8, water pump 16, water storage tank 11. The side wall of the fume hood 20 is provided with an openable manual feeding window 19 . The multi-layer atomizer 8 is connected to the end of the exhaust pipe 6 away from the exhaust fan 5, the water pump 16 is arranged on the side of the water storage tank 11, and a filter screen 12 is arranged in the storage water tank 11, and the filter screen 12 connects the water storage tank 11 is divided into a water purification area 15 and a sewage area 14. The water pump 16 extends to the water purification area 15 of the water storage tank 11. The water outlet of the water pump 16 is connected to the water inlet joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com