Oscillating conveyer for cupola deslagging and deslagging method thereof

A vibrating conveyor and cupola technology, applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of low slag removal, dirty, no practical application value, etc., to ensure continuous operation and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

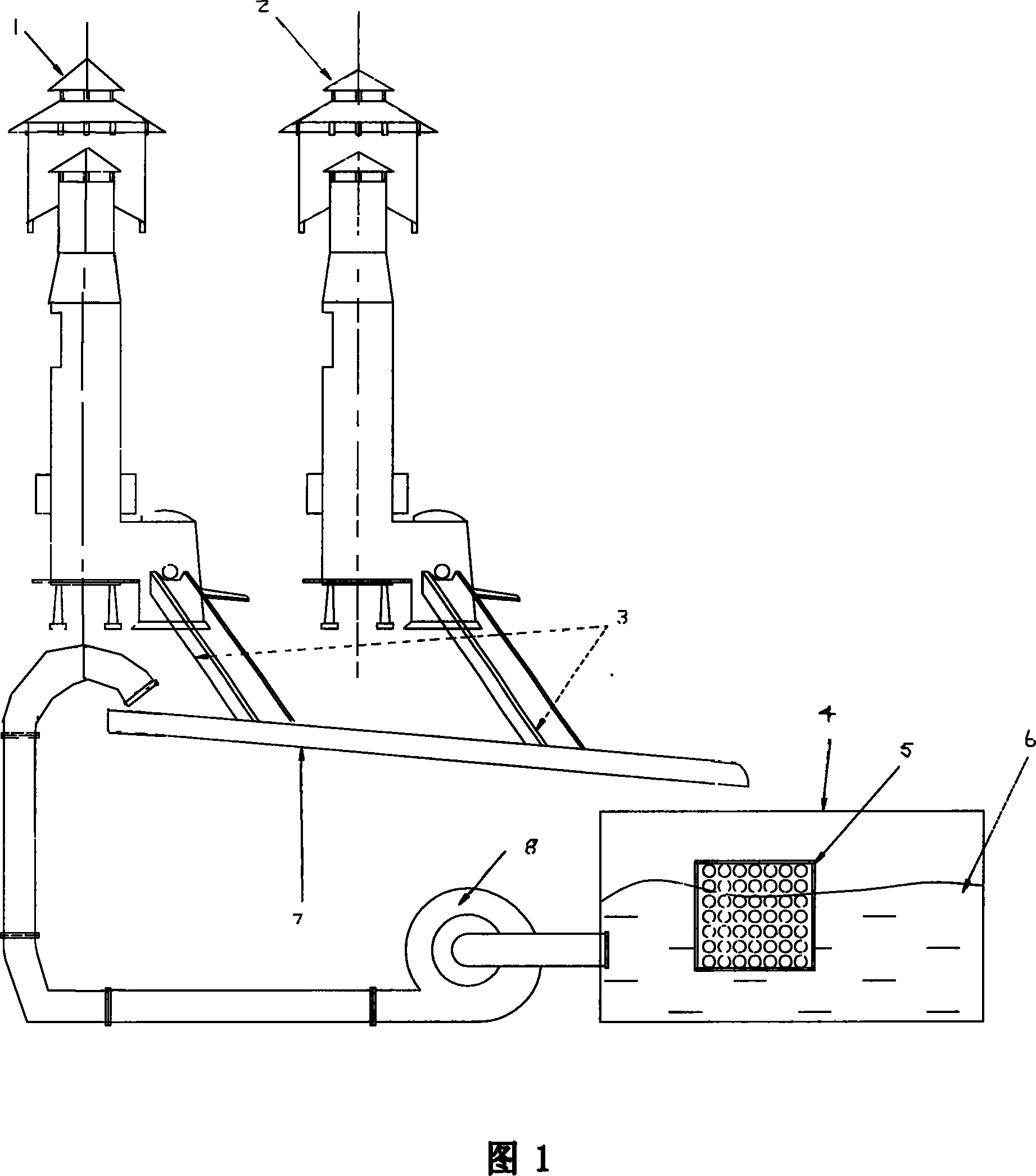

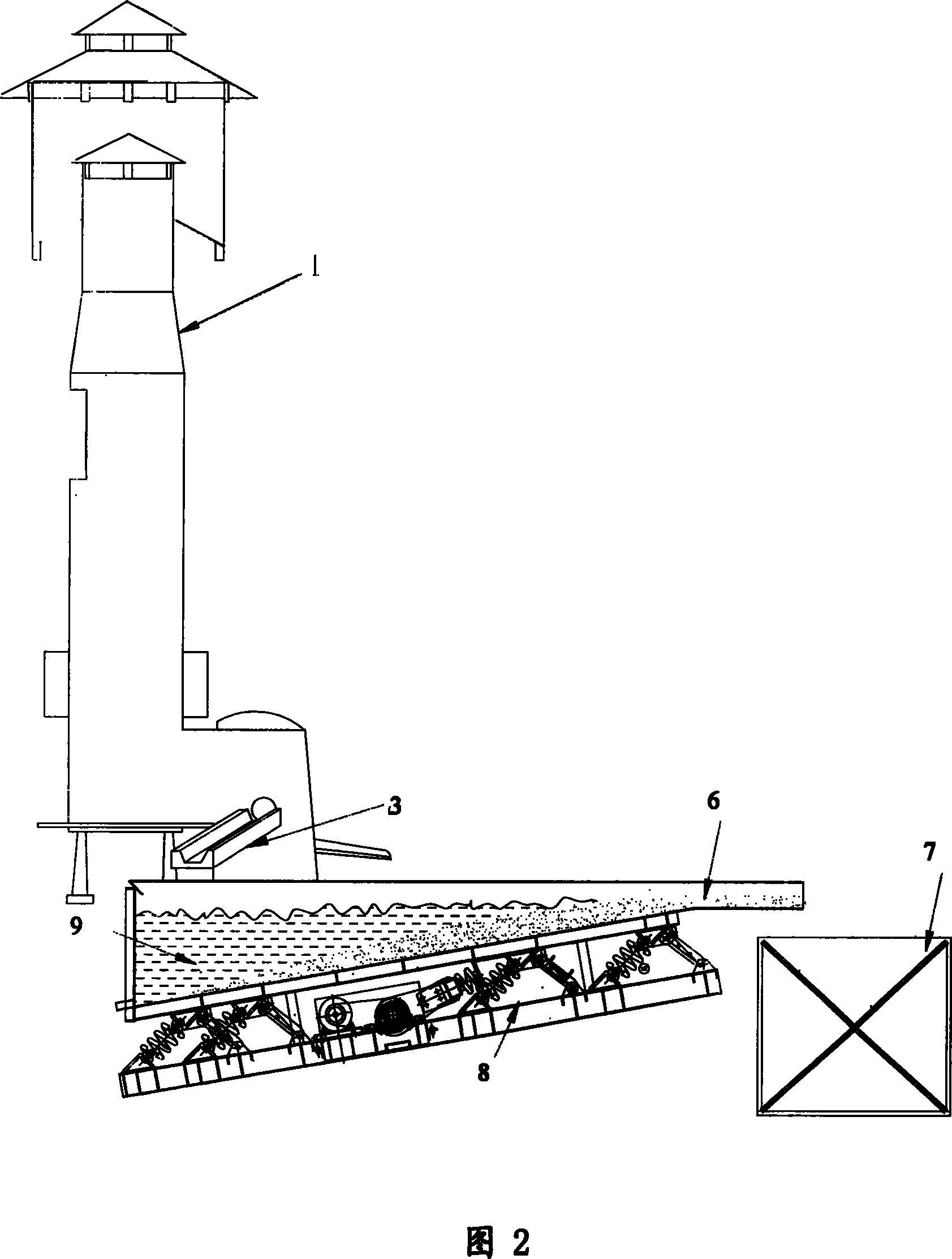

[0026] Below in conjunction with accompanying drawing and specific embodiment, vibrating conveyor for cupola slag removal of the present invention and its slag removal method are described in further detail:

[0027] As shown in Fig. 2, the cupola 1 according to the present invention discharges the slag 6 into the deep part of the water 9 in the vibrating conveyor 8 through the slagging tank 3 for cooling.

[0028] The cooled slag 6 is discharged by the vibrating conveyor 8 and falls into the slag bucket 7, while the water 9 flows back to the vibrating conveyor 8 for recycling.

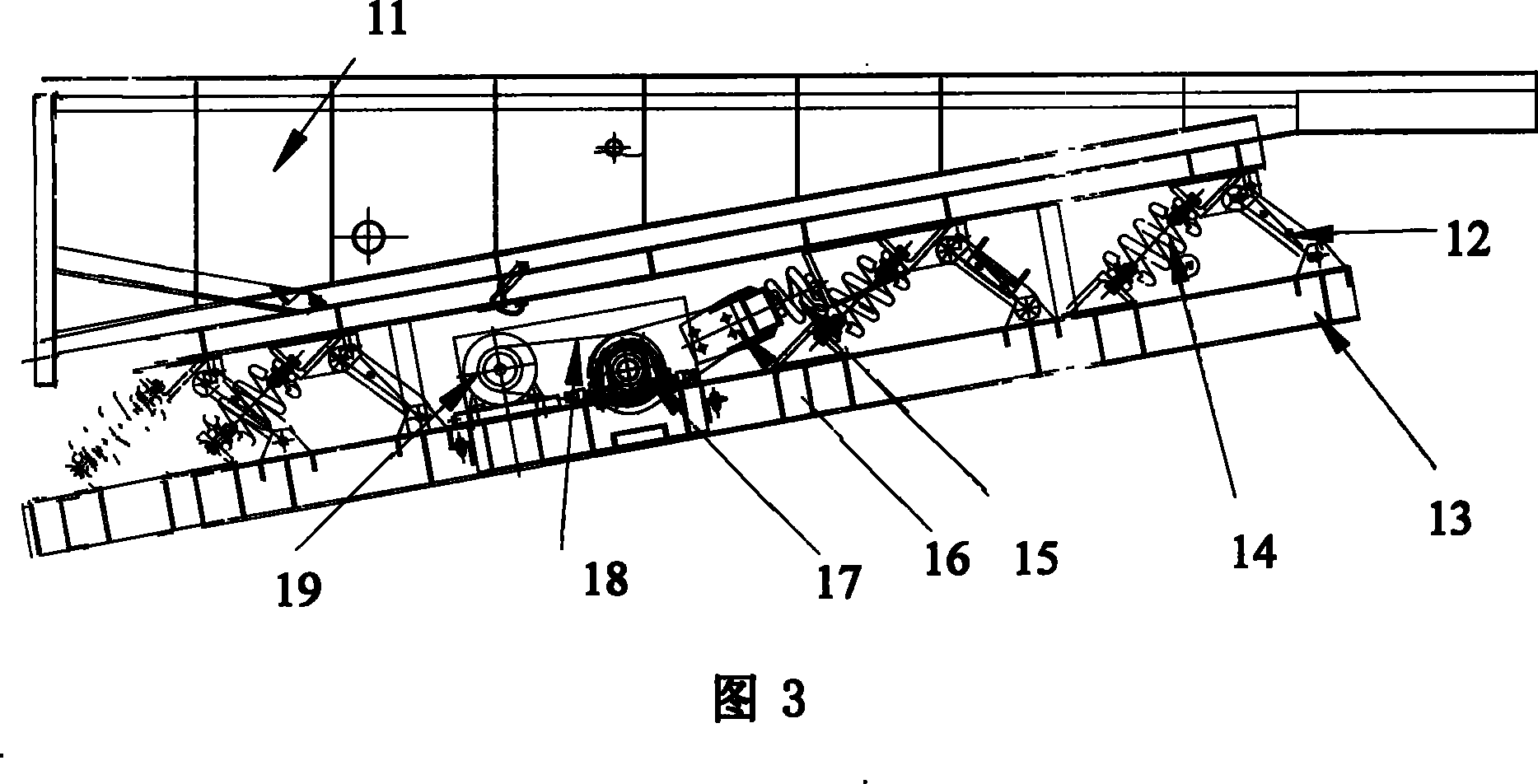

[0029] As shown in Figure 3, the vibrating conveyor 8 for cupola slag removal includes a slag water tank 11, a base 13, a movable connection device and a power unit, and the slag discharge tank 3 in the cupola 1 discharges the slag 6 to the slag water tank 11 Among them, the bottom surface of the slag water tank 11 is an inclined plane, and the longitudinal section of the slag water tank 11 is a right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com