Dedusting system used for cupola

A technology of dust removal system and cupola, which is applied in the field of dust removal, can solve the problems of small processing capacity and inconspicuous effect, and achieve the effects of increased processing capacity, obvious processing effect and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

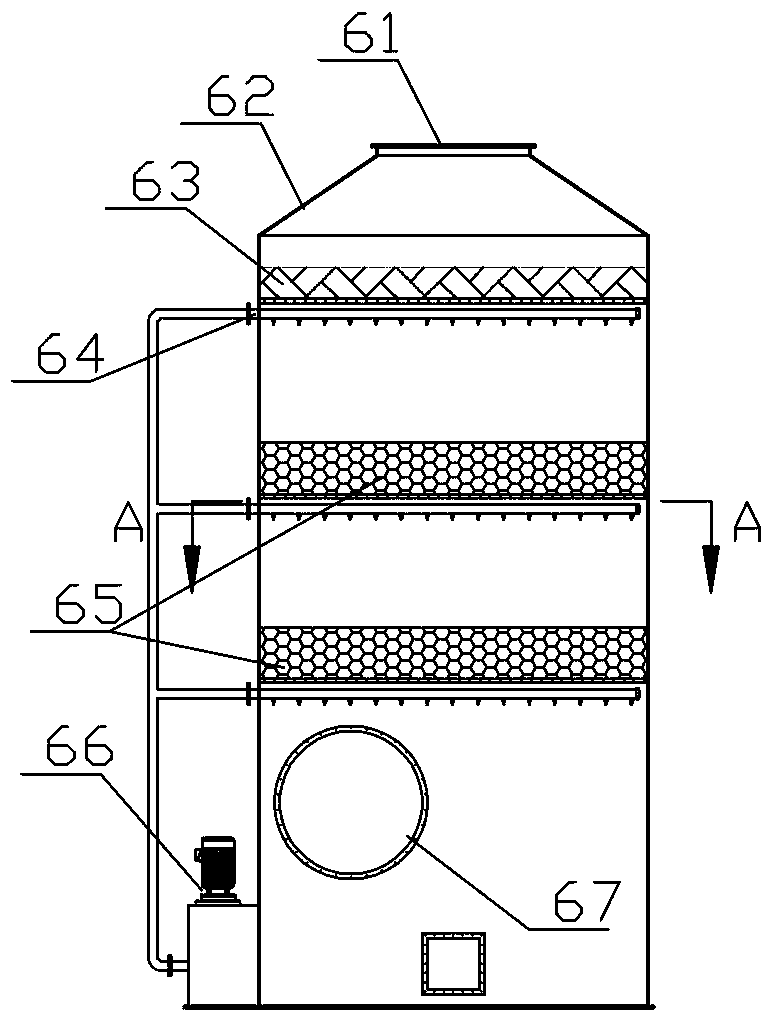

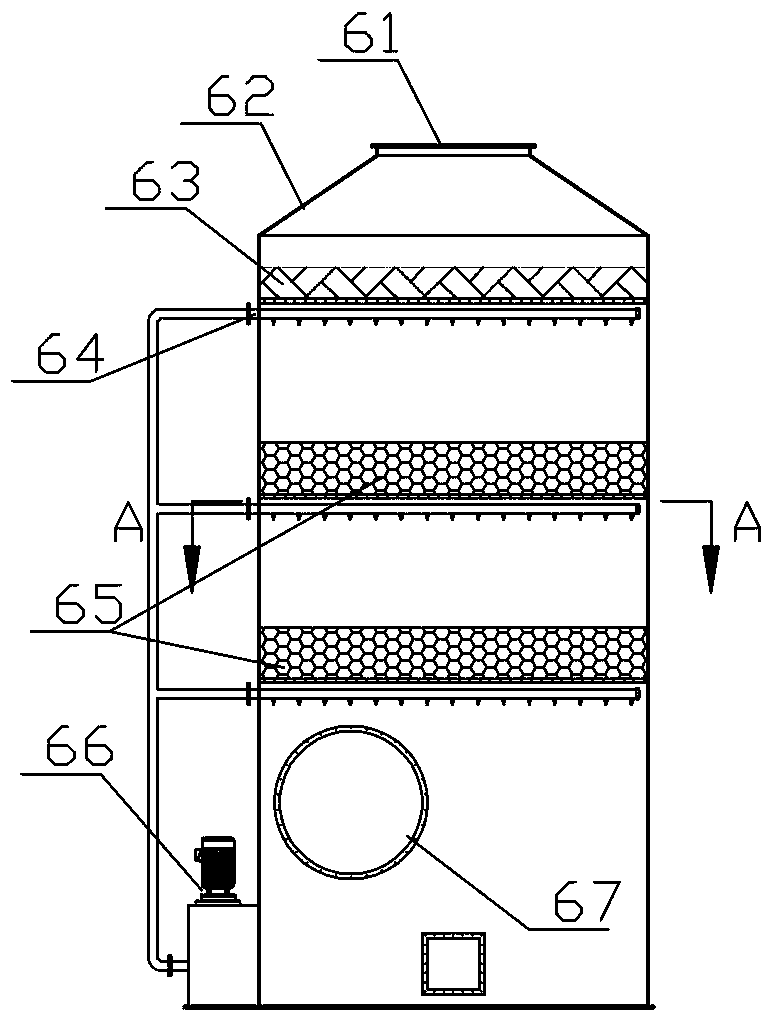

[0012] see Figure 1-3 , the present embodiment comprises the dust collecting hood 2 that is installed on the smoke outlet of the cupola 1 furnace top, the dust collecting hood 2 is connected with an induced draft fan A3 through a pipeline, and the induced draft fan A3 is connected with the air inlet of a cyclone dust collector 4, The air outlet of the cyclone dust collector 4 is connected to the air inlet of a spray tower 6 through a pipeline equipped with an induced draft fan B5, and the air outlet of the spray tower 6 is connected to the air inlet of a dehydrator 7 through a pipeline, and the dehydrator The air outlet of 7 is connected with the inlet of a chimney 9 by the pipeline that induced draft fan C8 is housed.

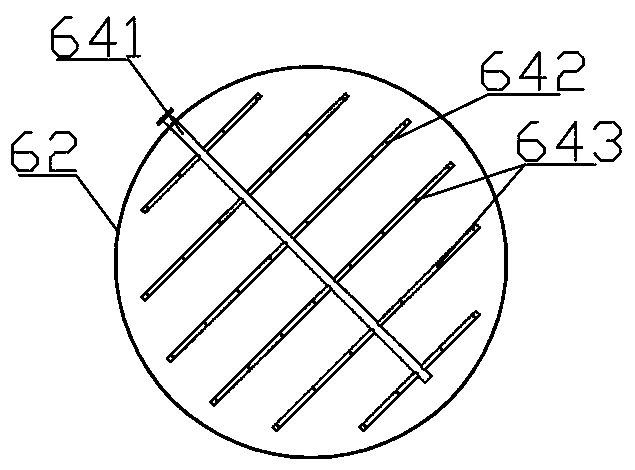

[0013] The spray tower 6 described in this embodiment includes a tank body 62, the top of the tank body 62 is provided with a spray tower gas outlet 61, the side wall of the lower end of the tank body 62 is provided with a spray tower air inlet 67, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com