Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

An anti-corrosion coating and corrosion-resistant technology, used in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as easy corrosion and rust, achieve rapid drying, improve coating efficiency, and excellent weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0021] Embodiment 1-3 The preparation method of the anti-corrosion coating for the outer wall of weather-resistant and corrosion-resistant steel pipes, comprising the following steps:

[0022] Add the hydrocarbon solvent in the formula (that is, the mixture of xylene and toluene) into the tank first, then slowly add alkyd resin, epoxy resin and terpene resin in sequence and stir evenly in time. Stop stirring after the resin is completely mixed, add anti-corrosion agent and drier, and stir well, then stop stirring. Adjust the viscosity (15-28s, apply 4 viscosity cups) and solids (≥35%) to the acceptable range, filter and pack.

Embodiment 4

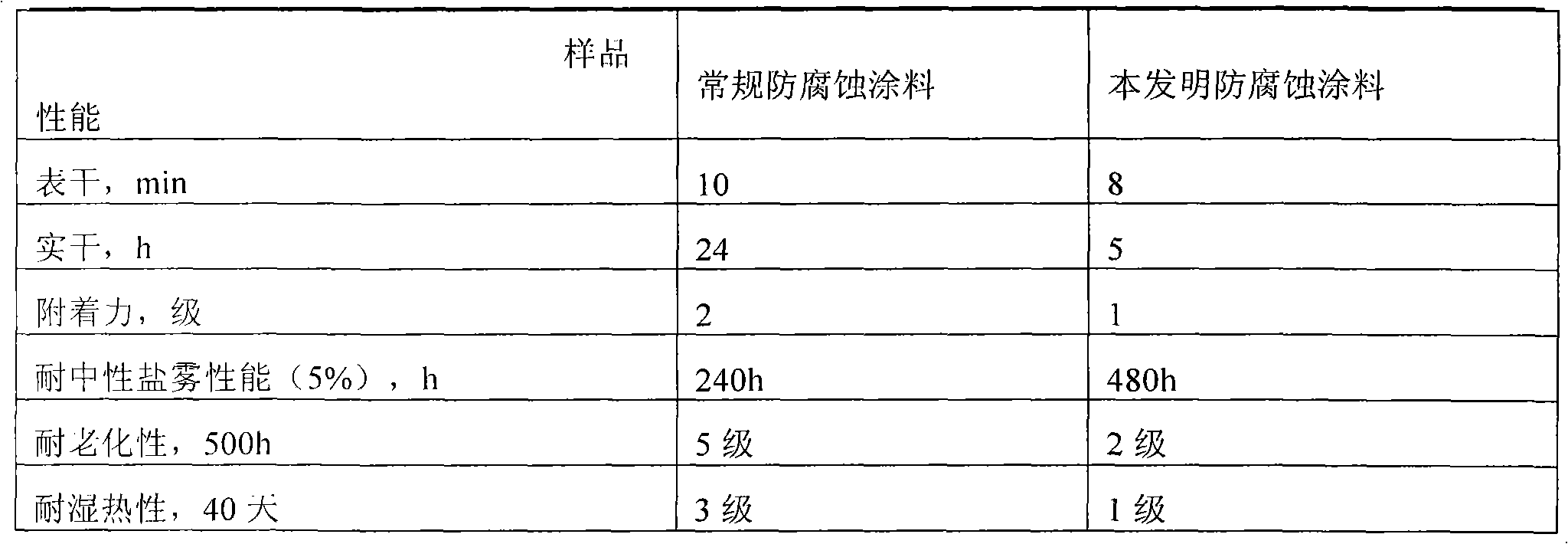

[0024] The conventional anti-corrosion coating and the anti-corrosion coating of the present invention are made into plates under the same conditions, and the surface drying time, hard drying time, adhesion, neutral salt spray resistance, aging resistance and heat and humidity resistance of the two coating films are compared. , and the results are shown in Table 1.

[0025] From the results of comparative experiments, the anti-corrosion coating prepared by the present invention has rapid drying, good adhesion, excellent salt spray resistance, weather resistance and heat and humidity resistance, and can provide steel pipes under various harsh natural conditions. Excellent corrosion protection.

[0026] Table 1 Conventional anti-corrosion paint and performance contrast of anti-corrosion paint of the present invention

[0027]

Embodiment 5

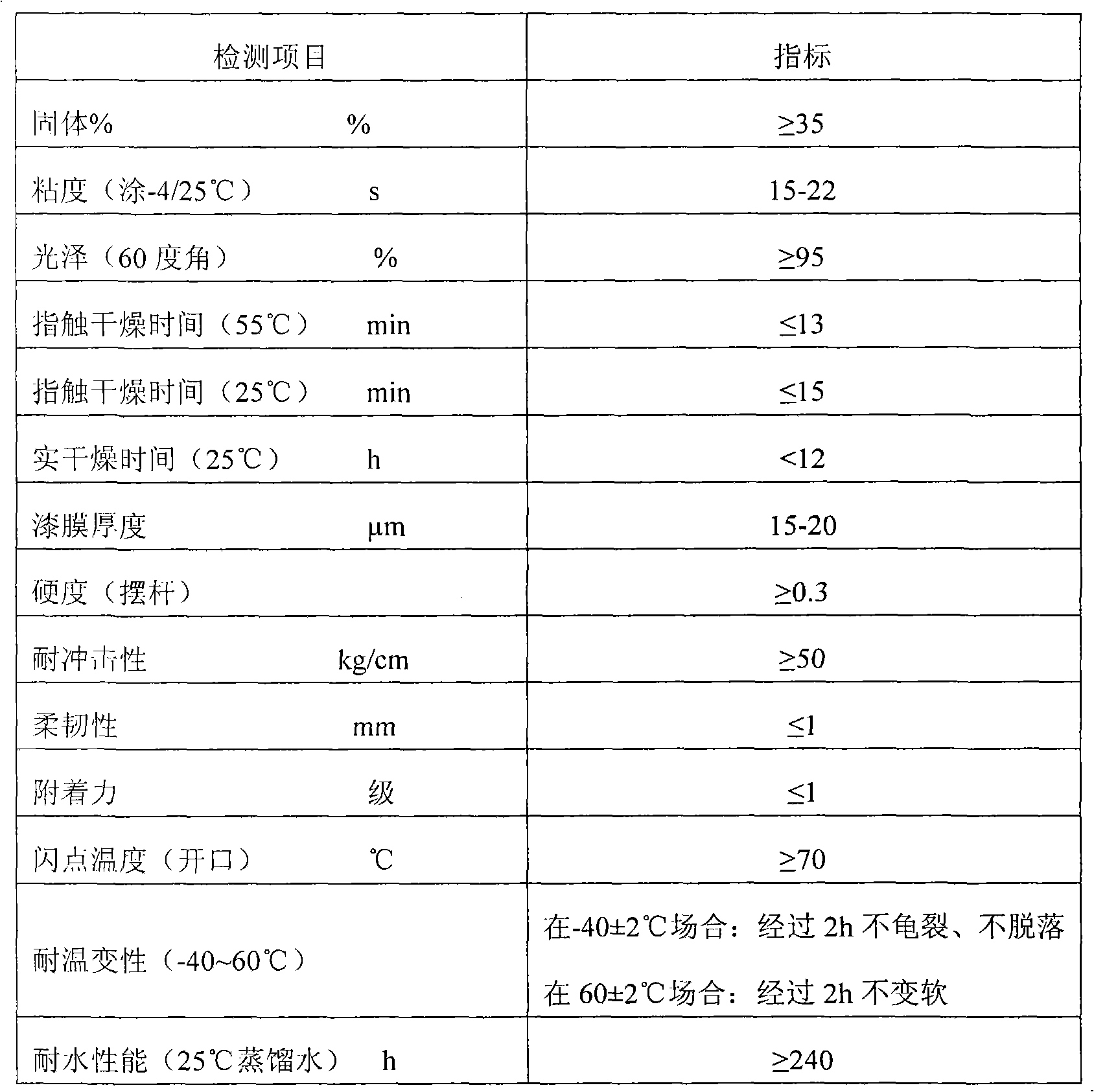

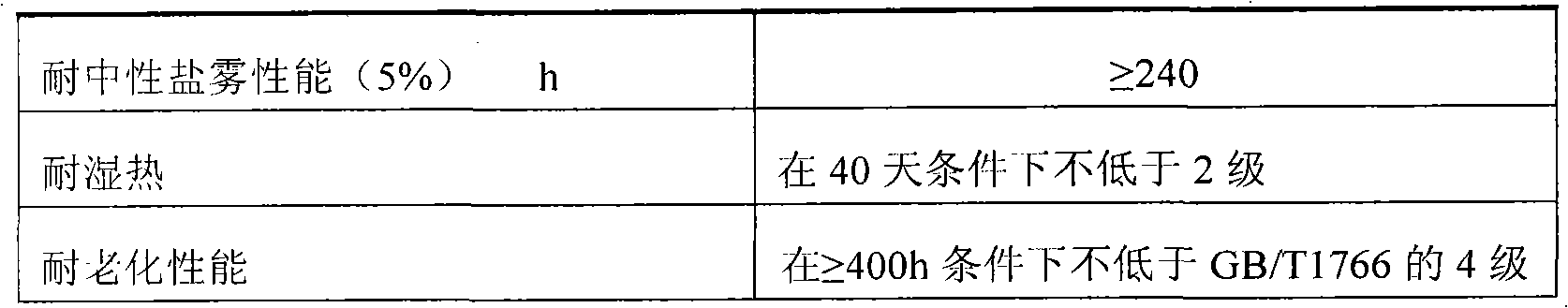

[0029] After passing the anti-corrosion coating on the outer wall of the weather-resistant and corrosion-resistant steel pipes of the above-mentioned embodiments through a 200-mesh net, and then applying one of the methods of brushing, spraying, showering or dipping, the coating film can reach 24 hours later. Properties listed in Table 2.

[0030] Table 2 Inspection indicators of anti-corrosion coatings for outer walls of weather-resistant and corrosion-resistant steel pipes

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com