Method for preventing NdFeB permanent magnet from being corroded

A permanent magnet and anti-corrosion technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of the decline of the magnetic properties of NdFeB permanent magnets, the insufficient corrosion resistance of NdFeB permanent magnets, and the foaming of NdFeB permanent magnets. and other problems, to achieve the effects of low cost, reliable bonding, and improved magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

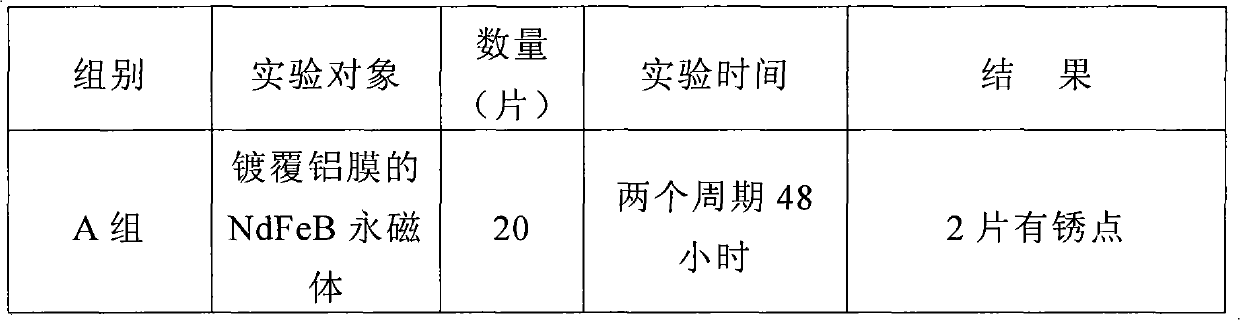

Examples

Embodiment Construction

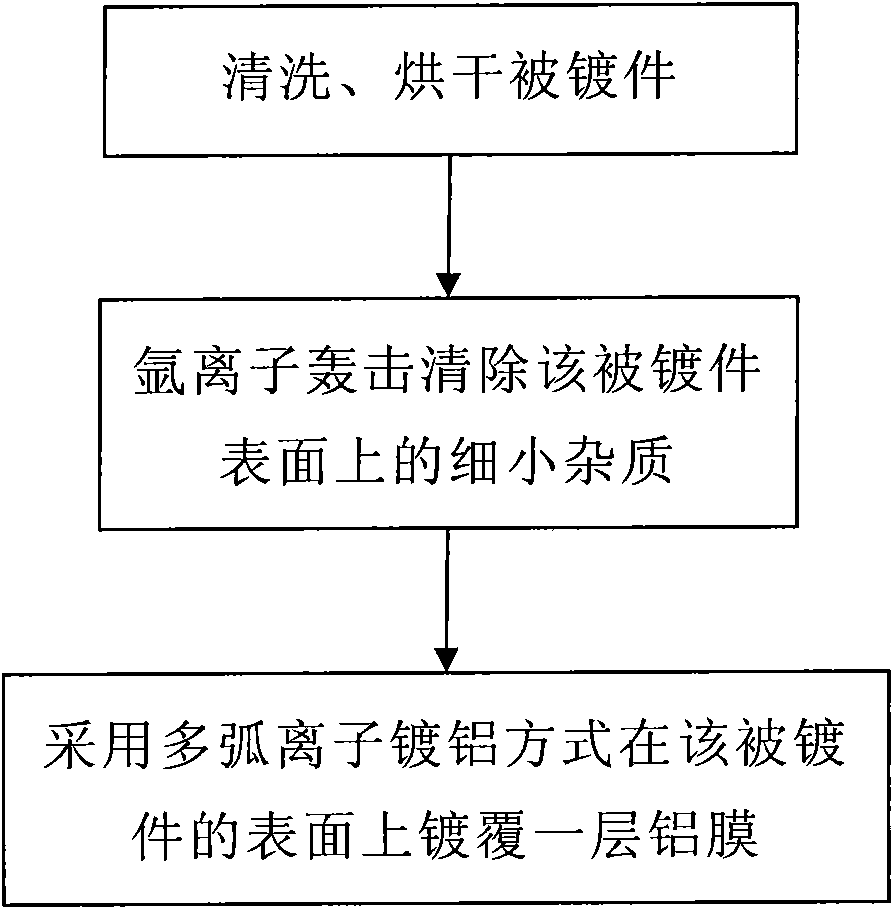

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] The NdFeB permanent magnet anti-corrosion method of the present invention is realized based on an existing coating machine (belonging to the prior art, not described in detail here). Generally, an existing coating machine includes a vacuum chamber, a vacuum pump, an argon ion bombardment component, a multi-arc ion coating component, a hanger and a rotation control component. The vacuum pump is used to evacuate the vacuum chamber, and the hanger is used to hang the The plated piece, the rotation control component is used to control the rotation of the hanger, the argon ion bombardment component includes an argon ion bombardment power supply and an argon ion bombardment emission device, and the argon ion bombardment emission device is used to emit argon ions, multi-arc ion The coating component includes an arc power source and a target, the arc power source cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com