Preparation method of modified titanium oxide coating applied to metal matrix corrosive protection

A metal substrate and corrosion protection technology, applied in coatings, anti-corrosion coatings, and devices for coating liquid on the surface, can solve problems such as metal substrate failure, coating damage, local corrosion, etc., and achieve improved application life and thickness. control, surface smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

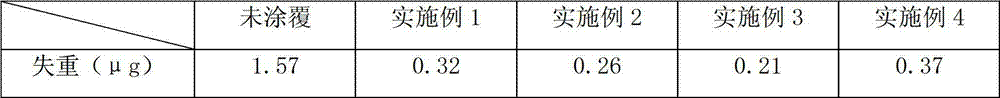

Examples

Embodiment 1

[0028] (1) Use an anhydrous pipette to pipette 10ml of butyl titanate, measure 50ml of absolute ethanol in a graduated cylinder, and mix to make solution A; measure and mix 10ml of deionized water, 10ml of glacial acetic acid and 20ml of absolute ethanol, and weigh Add 0.15g of tin tetrachloride crystals (the molar ratio to butyl titanate is 1:50) and stir to dissolve to form solution B; mix solution A and solution B under stirring to obtain light yellow transparent sol, sol Placed at room temperature for aging for 24 hours, it turned into a solid gel.

[0029] (2) Put the obtained solid gel into a drying oven to fully dry to obtain a loose powder, grind the powder with a mortar and put it in a crucible, put it into a muffle furnace and raise the temperature to 400 at a speed of less than 3K / min ℃ for 30 minutes to obtain tin oxide composite modified nano-titanium oxide powder.

[0030] (3) Measure 5ml of γ-methacryloxypropyltrimethoxysilane, 5ml of water and 90ml of ethanol,...

Embodiment 2

[0034] (1) Use an anhydrous pipette to pipette 10ml of butyl titanate, measure 50ml of absolute ethanol in a graduated cylinder, and mix to make solution A; measure and mix 10ml of deionized water, 10ml of glacial acetic acid and 20ml of absolute ethanol, and weigh Add 0.20g of tin tetrachloride crystals (the molar ratio to butyl titanate is about 1:40) and stir to dissolve to make solution B; mix solution A and solution B under stirring to obtain a light yellow transparent sol, The sol was aged at room temperature for 24 hours and transformed into a solid gel.

[0035] (2) Put the obtained solid gel into a drying oven to fully dry to obtain a loose powder, grind the powder with a mortar, put it in a crucible, put it into a muffle furnace and raise the temperature to 450 at a speed of less than 3K / min ℃ for 30 minutes to obtain tin oxide composite modified nano-titanium oxide powder.

[0036] (3) Measure 7ml of γ-methacryloxypropyltrimethoxysilane, 7ml of water and 86ml of et...

Embodiment 3

[0041] (1) Use an anhydrous pipette to pipette 10ml of butyl titanate, measure 50ml of absolute ethanol in a graduated cylinder, and mix to make solution A; measure and mix 10ml of deionized water, 10ml of glacial acetic acid and 20ml of absolute ethanol, and weigh Add 0.25g of tin tetrachloride crystals (the molar ratio to butyl titanate is 1:30) and stir to dissolve to form solution B; mix solution A and solution B under stirring to obtain a light yellow transparent sol, and The sol was aged at room temperature for 24 hours and transformed into a solid gel.

[0042] (2) Put the obtained solid gel into a drying oven to fully dry to obtain a loose powder, grind the powder with a mortar, put it in a crucible, put it into a muffle furnace and raise the temperature to 500 at a speed of less than 3K / min ℃ for 30 minutes to obtain tin oxide composite modified nano-titanium oxide powder.

[0043](3) Measure 9ml of γ-methacryloxypropyltrimethoxysilane, 9ml of water and 82ml of ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com