Pitch bearing of wind turbine generator and anti-corrosion processing method of pitch bearing

A pitch bearing and anti-corrosion treatment technology, which is applied in the pitch field of wind turbines, can solve the problems that offshore wind turbines are difficult to reach the service life, the bearing capacity of pitch bearings is reduced, and the sealing performance of pitch bearings is reduced, so as to improve anti-corrosion The effect of protecting, improving bearing capacity and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

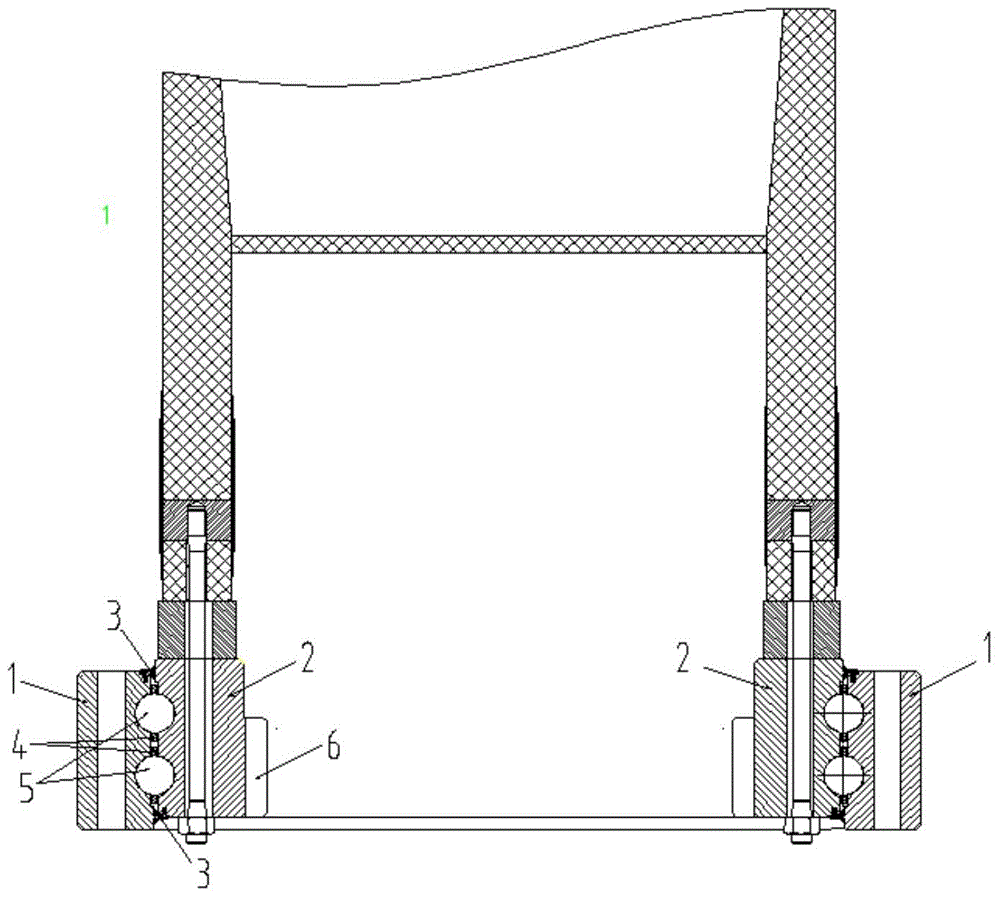

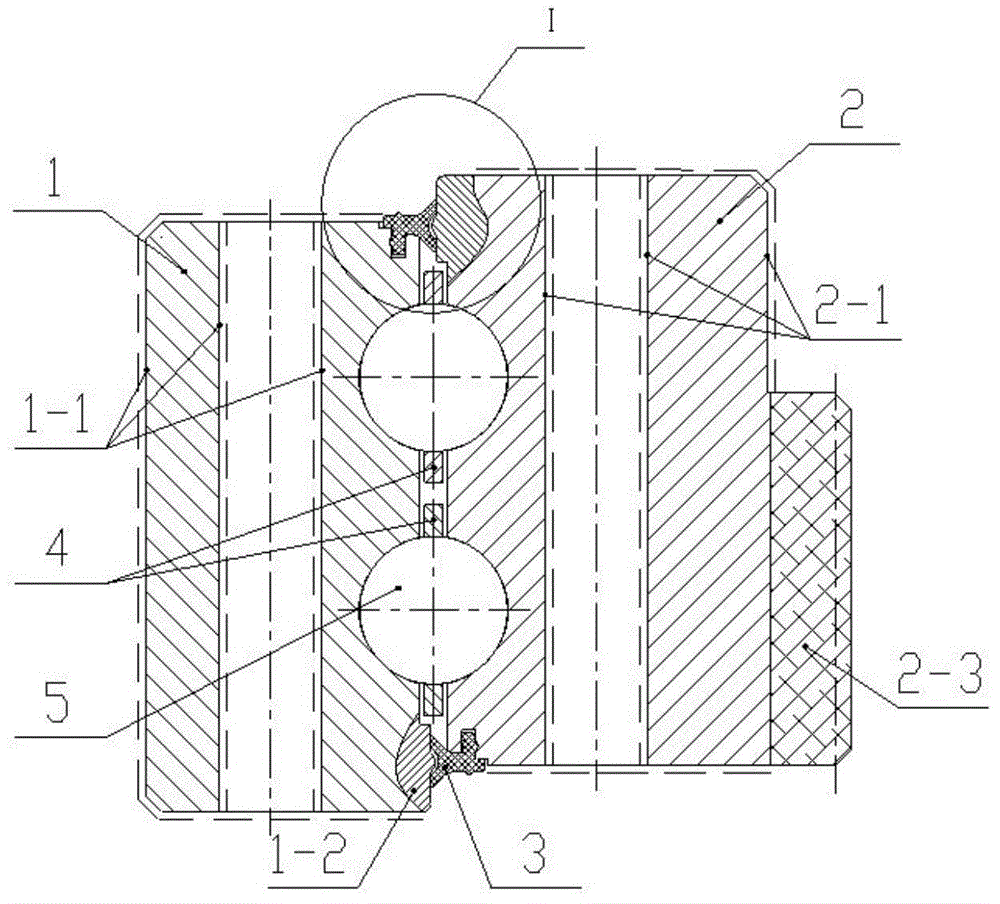

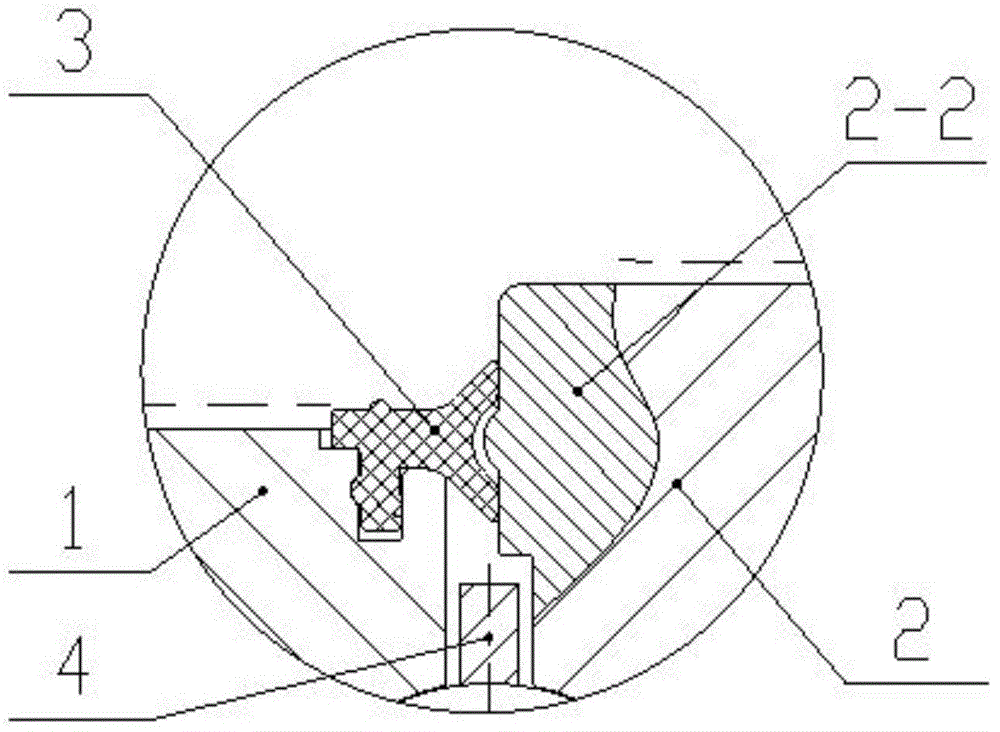

[0028] Refer to attached figure 1 and 2 It can be seen that this embodiment relates to a pitch bearing of an offshore wind power generator set, the pitch bearing includes a bearing outer ring 1, a bearing inner ring 2 and a rolling element 5, and the rolling element 5 is fixed on the bearing inner ring 2 through a cage 4 Between the bearing outer ring 1 and the inner wall of the bearing inner ring 2, there are driving teeth 6, which are beneficial to mesh with the pitch driving teeth to complete the rotation of the bearing inner ring 2. The upper and lower joint lips of the bearing inner ring 2 and the bearing outer ring 1 are provided with a sealing ring 3 to form the upper and lower sealing lips between the bearing inner ring 2 and the bearing outer ring 1 to maintain the contact between the rolling elements 5 and the cage 4 Sealing performance.

[0029] In this embodiment, the main parts of the bearing outer ring 1 and the bearing inner ring 2 are all made of 42CrMo mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com