Method for preparing composite coating at surface of neodymium iron boron permanent magnet

A technology of surface compounding and permanent magnets, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve problems such as gaps, ion plating surface roughness, etc., to improve corrosion resistance and low production cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

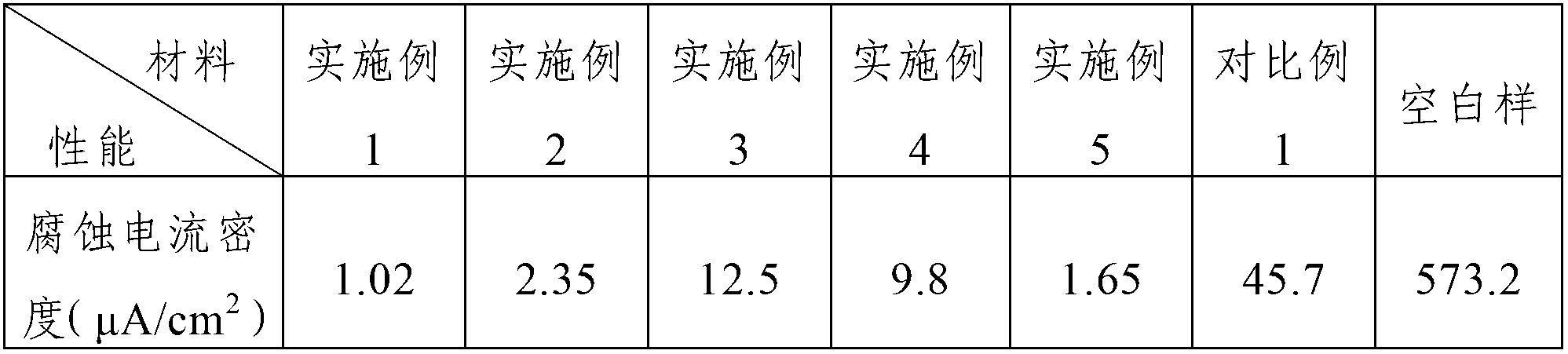

Embodiment 1

[0042] The preparation method of the composite coating on the surface of the NdFeB permanent magnet of this embodiment comprises the following steps:

[0043] Step 1. Surface pretreatment of NdFeB permanent magnets with a size of Φ15mm×3mm:

[0044] Step 101, using 400#, 600#, 800#, 1000# and 1200# sandpaper in sequence to polish the NdFeB permanent magnet;

[0045] Step 102, placing the polished NdFeB permanent magnet in step 101 in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; the temperature of the ultrasonic-assisted degreasing treatment is 75°C, and the The time for the ultrasonic-assisted degreasing treatment is 3min; the degreasing liquid is prepared by mixing sodium hydroxide, sodium carbonate, sodium pyrophosphate, OP-10 and deionized water, wherein the concentration of sodium hydroxide is 12g / L , the concentration of sodium carbonate is 45g / L, the concentration of sodium pyrophosphate is 55g / L, and the concentratio...

Embodiment 2

[0055] The preparation method of the composite coating on the surface of the NdFeB permanent magnet of this embodiment comprises the following steps:

[0056] Step 1. Surface pretreatment of NdFeB permanent magnets with a size of Φ20mm×3mm:

[0057] Step 101, using 400#, 600#, 800#, 1000# and 1200# sandpaper in sequence to polish the NdFeB permanent magnet;

[0058] Step 102, placing the polished NdFeB permanent magnet in step 101 in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; the temperature of the ultrasonic-assisted degreasing treatment is 70°C, and the The time for the ultrasonic-assisted degreasing treatment is 5min; the degreasing liquid is prepared by mixing sodium hydroxide, sodium carbonate, sodium pyrophosphate, OP-10 and deionized water, wherein the concentration of sodium hydroxide is 15g / L , the concentration of sodium carbonate is 50g / L, the concentration of sodium pyrophosphate is 60g / L, and the concentratio...

Embodiment 3

[0066] The preparation method of the composite coating on the surface of the NdFeB permanent magnet of this embodiment comprises the following steps:

[0067] Step 1. Surface pretreatment of NdFeB permanent magnets with a size of Φ20mm×5mm:

[0068] Step 101, using 400#, 600#, 800#, 1000# and 1200# sandpaper in sequence to polish the NdFeB permanent magnet;

[0069] Step 102, placing the polished NdFeB permanent magnet in step 101 in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; the temperature of the ultrasonic-assisted degreasing treatment is 70°C, and the The time for the ultrasonic-assisted degreasing treatment is 5min; the degreasing liquid is prepared by mixing sodium hydroxide, sodium carbonate, sodium pyrophosphate, OP-10 and deionized water, wherein the concentration of sodium hydroxide is 15g / L , the concentration of sodium carbonate is 48g / L, the concentration of sodium pyrophosphate is 62g / L, the concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com