Making method of graphene modified titanium oxide metal anticorrosion coating

A technology of graphene modification and titanium oxide, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the difficulty of guaranteeing the mechanical properties and cathodic protection effect of the coating, the agglomeration of titanium oxide, and abnormal growth and other issues, to achieve the effect of improving electron transfer efficiency, low cost, and improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

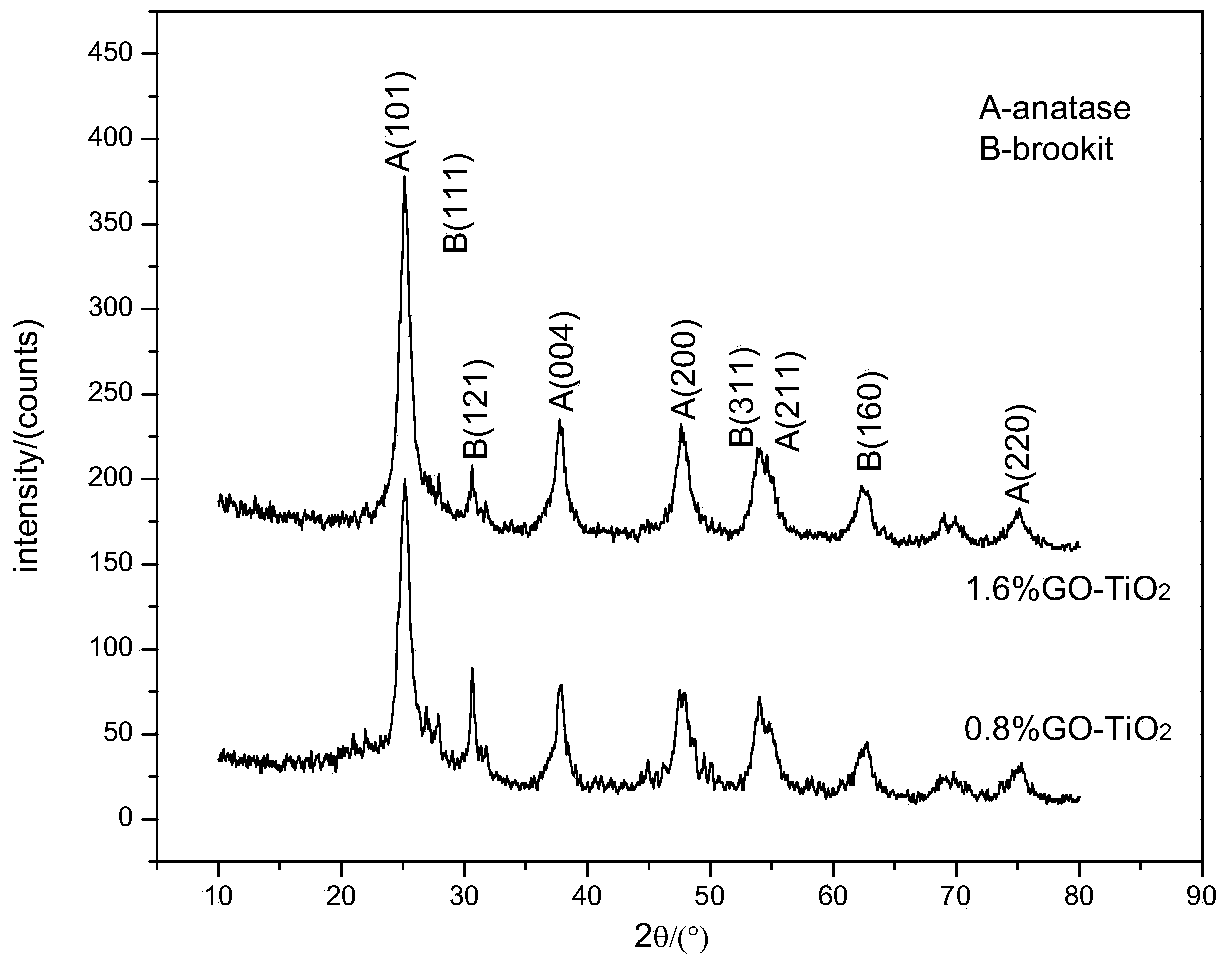

Image

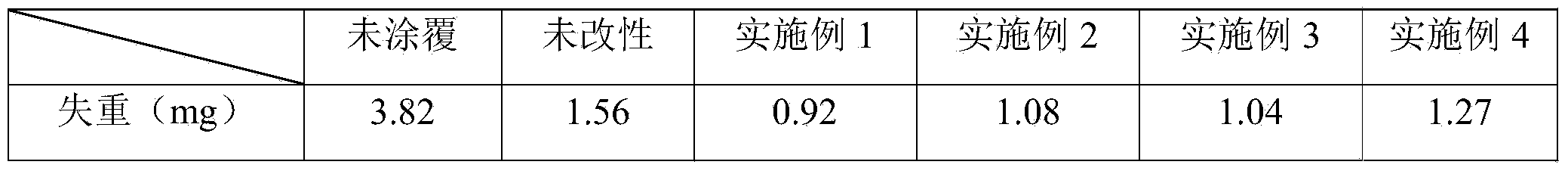

Examples

Embodiment 1

[0052] The preparation method of graphene modified titanium oxide metal anticorrosion coating comprises the steps:

[0053] The first step, the preparation steps of graphene precursor solution:

[0054] In parts by volume, measure 10 parts of graphene oxide aqueous solution and 30 parts of absolute ethanol with a concentration of 2 g / L respectively, mix them and place them in an ultrasonic cleaner for ultrasonic dispersion to prepare a graphene precursor solution;

[0055] The second step, the preparation step of titanium oxide sol:

[0056] In parts by volume, measure 10 parts of analytically pure butyl titanate and 50 parts of absolute ethanol respectively, mix and make A solution;

[0057] In parts by volume, measure 10 parts of deionized water, 10 parts of analytical pure glacial acetic acid and 20 parts of absolute ethanol respectively, and mix them to form solution B;

[0058] Stir and mix the above-mentioned solution A and solution B uniformly to obtain a titanium oxi...

Embodiment 2

[0073] In the first step, in the preparation step of the graphene precursor solution, measure 10 parts of absolute ethanol by volume;

[0074] In the second step, in the preparation step of titanium oxide sol, 40 parts of dehydrated alcohol are measured and mixed to form A solution according to the volume fraction; 10 parts of dehydrated alcohol are measured and mixed to form B solution;

[0075] In the third step, in the preparation step of graphene-modified titanium oxide powder, the reaction time in the hydrothermal reactor was 8 hours; the rest were the same as in Example 1.

Embodiment 3

[0077] In the first step, in the preparation step of the graphene precursor solution, measure 15 parts of graphene oxide aqueous solution with a concentration of 2 g / L and 20 parts of absolute ethanol in parts by volume;

[0078] In the second step, in the preparation step of titanium oxide sol, 30 parts of dehydrated alcohol are measured and mixed to form A solution according to the volume fraction; 20 parts of dehydrated alcohol are measured and mixed to form B solution;

[0079] In the third step, in the preparation step of graphene-modified titanium oxide powder, the reaction time in the hydrothermal reactor is 12 hours;

[0080] In the fifth step, in the preparation step of the graphene oxide / titanium dioxide composite coating, the graphene oxide / titanium dioxide composite powder is added in an amount of 8g per liter of silane sol;

[0081] All the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com