Method for improving methane yield of sludge anaerobic digestion by utilizing iron/carbon/biological enzyme coupling technology

An anaerobic digestion and biological enzyme technology, applied in the field of municipal engineering sludge treatment and environmental engineering, can solve the problems of low biogas production, low substrate conversion rate, low operating cost, etc., to improve the promotion effect, enhance microbial activity, The effect of enhancing resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for increasing the amount of methane produced in sludge anaerobic digestion using iron / charcoal / biological enzyme coupling technology, comprising the following steps:

[0035] (1) Obtain the concentration tank sludge of sewage treatment plant, its pH value is 6.84, TSS is 17.4g / L, and VSS is 11.6g / L;

[0036](2) Weigh 5g of liquor koji and place it in a 250mL conical flask, add 100mL of distilled water, place in a constant temperature water bath at 35°C for 0.5h, then use medium-speed quantitative filter paper to carry out suction filtration, and sieve out large particles and some molds and yeasts to obtain The leachate is used for later use; Baijiu koji is purchased from Angel Yeast Co., Ltd. Baijiu koji is rich in various microorganisms, among which yeast and mold are the main ones. Enzymes, etc., can decompose organic matter in municipal sludge, and large particles and some mold and yeast can be removed by suction filtration, so as not to affect the subseque...

Embodiment 2

[0042] A method for increasing methane production during sludge anaerobic digestion using iron / charcoal / biological enzyme coupling technology, comprising the following steps:

[0043] (1) Obtain sludge from the concentration tank of sewage treatment plant, its pH value is 6.52, TSS is 26.3g / L, VSS is 12.3g / L;

[0044] (2) Weigh 20g of liquor koji and place it in a 250mL conical flask, add 100mL of distilled water, place it in a constant temperature water bath at 40°C for 1 hour, then use a medium-speed quantitative filter paper to carry out suction filtration, sieve out large particles and some molds and yeasts, and obtain the immersion The filtrate is ready for use;

[0045] (3) The sludge is injected into 4 reaction containers in equal amounts, and except for the blank, 0.16g nanometer zero-valent iron+0.192g activated carbon+8mL liquor koji leaching filtrate is added respectively in the remaining three reaction containers; 0.16g Nano zero-valent iron + 0.192g activated car...

Embodiment 3

[0050] A method for increasing the amount of methane produced in sludge anaerobic digestion using iron / charcoal / biological enzyme coupling technology, comprising the following steps:

[0051] (1) Obtain sludge from the concentration tank of sewage treatment plant, its pH value is 6.73, TSS is 17.3g / L, and VSS is 12.4g / L;

[0052] (2) Weigh 30g of white wine koji and put it in a 250mL conical flask, add 100mL of distilled water, put it in a constant temperature water bath at 45°C for 1.5h, then use a medium-speed quantitative filter paper to carry out suction filtration, and sieve out large particles and some molds and yeasts to obtain The leachate is ready for use;

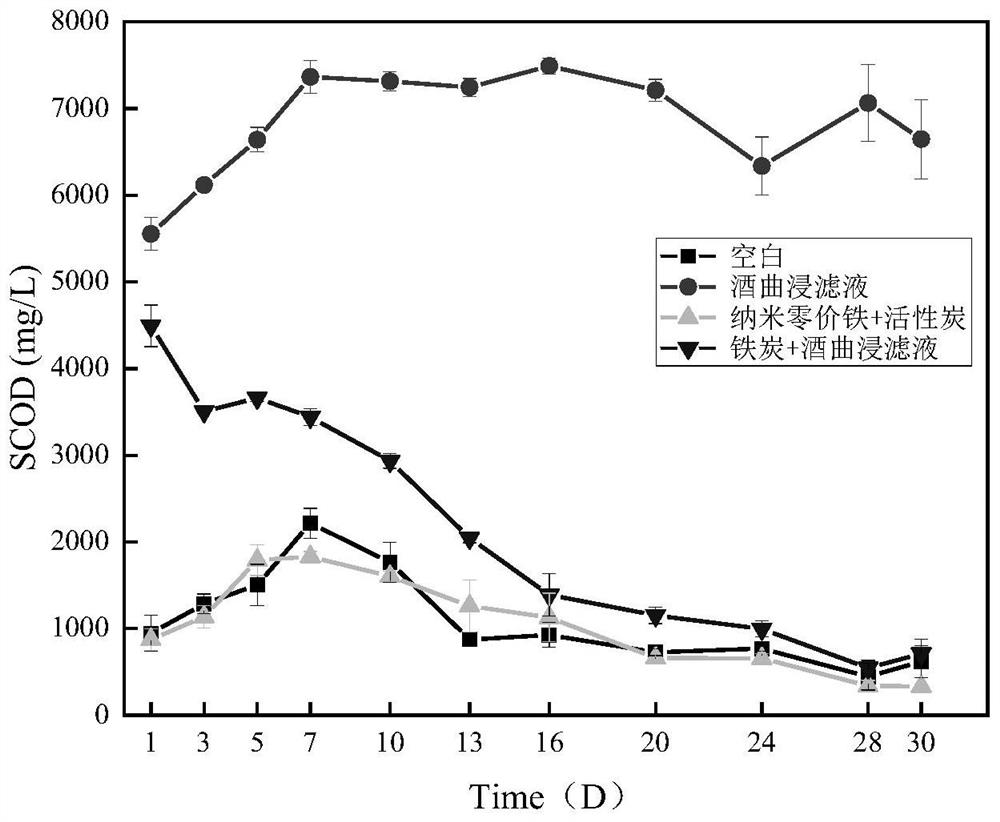

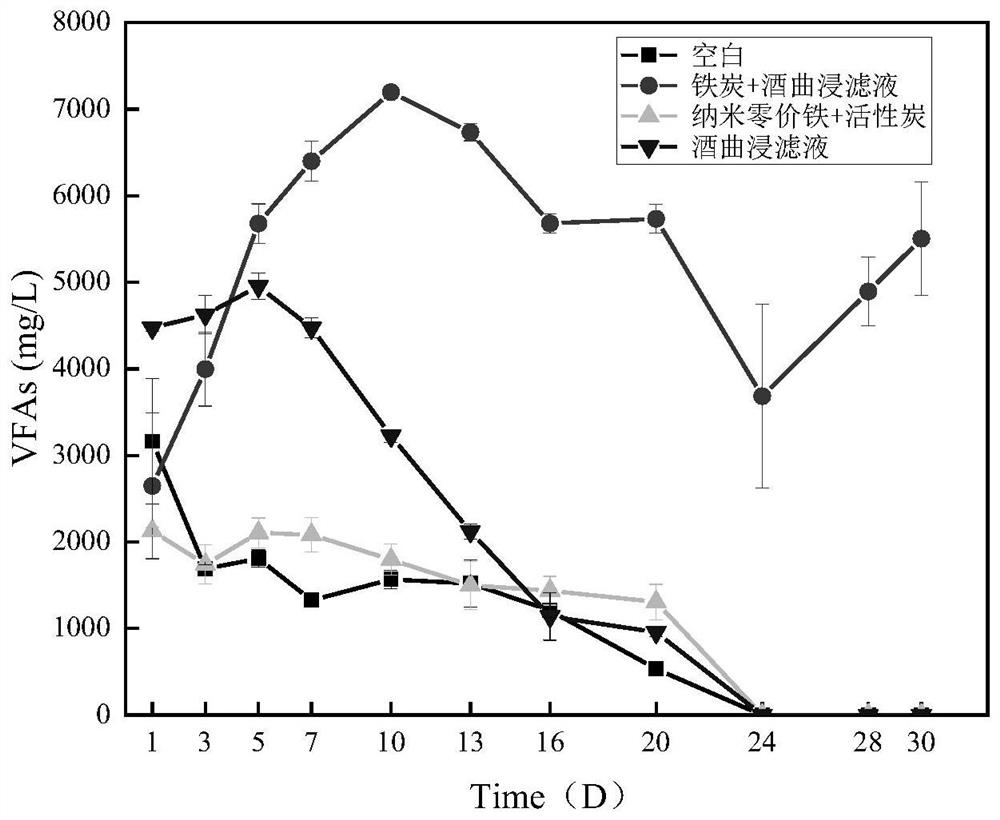

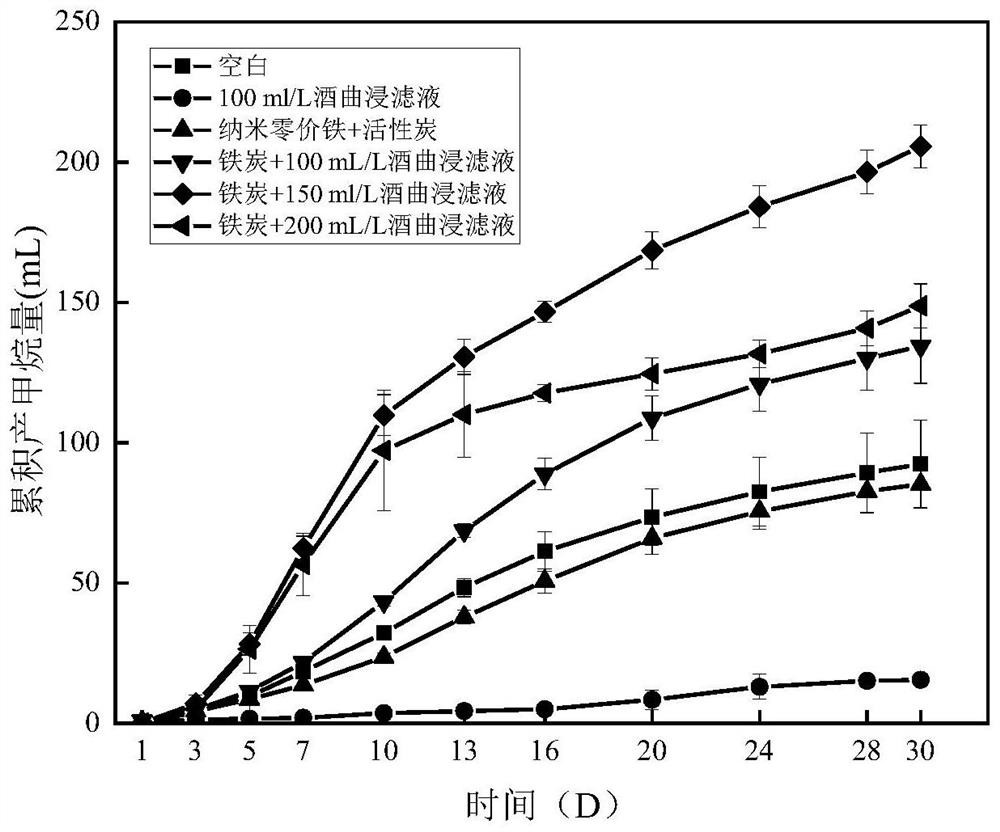

[0053] (3) The sludge is injected into 6 reaction vessels in equal amounts, except for the blank, add 0.16g nanometer zero-valent iron+0.192g activated carbon+100ml / L liquor koji leaching filtrate respectively in the remaining three reaction vessels; 0.16g nanometer zero valent iron + 0.192g activated carbon + 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com