Leakage on-line detection method for weld joint of petroleum and natural gas pipeline

An oil and natural gas and detection method technology, applied in the field of oil and natural gas pipeline leak detection, can solve problems such as poor real-time performance of detection methods, and achieve the effect of low power consumption, low cost, and low cost real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

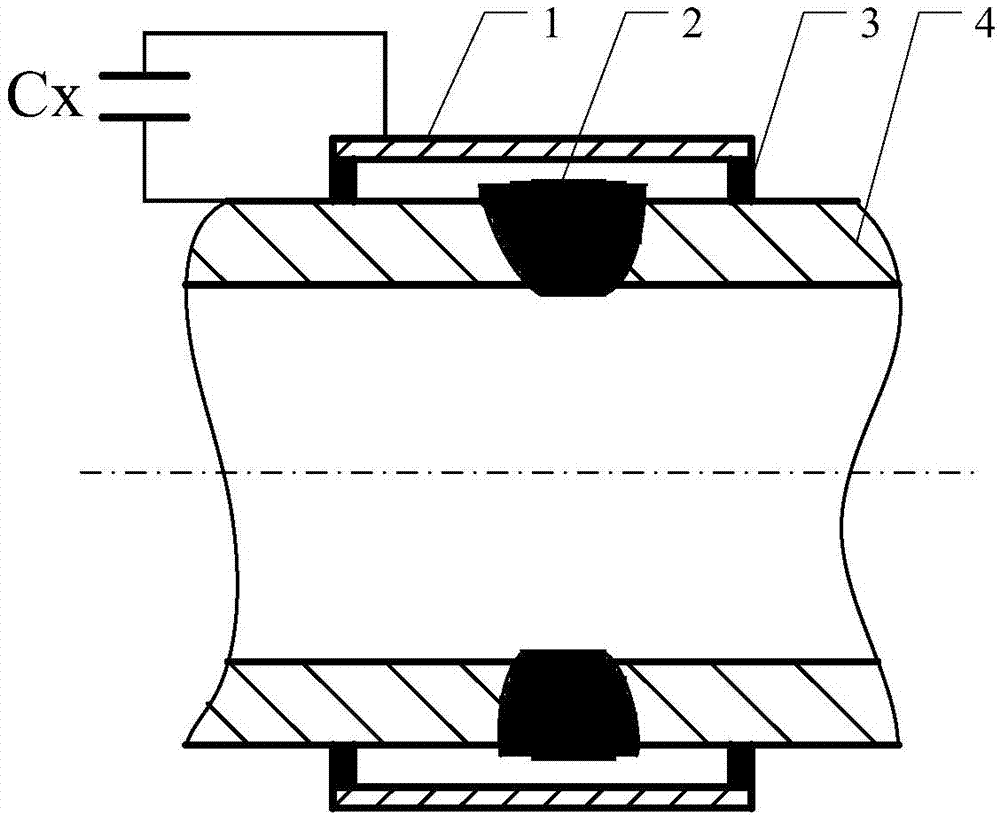

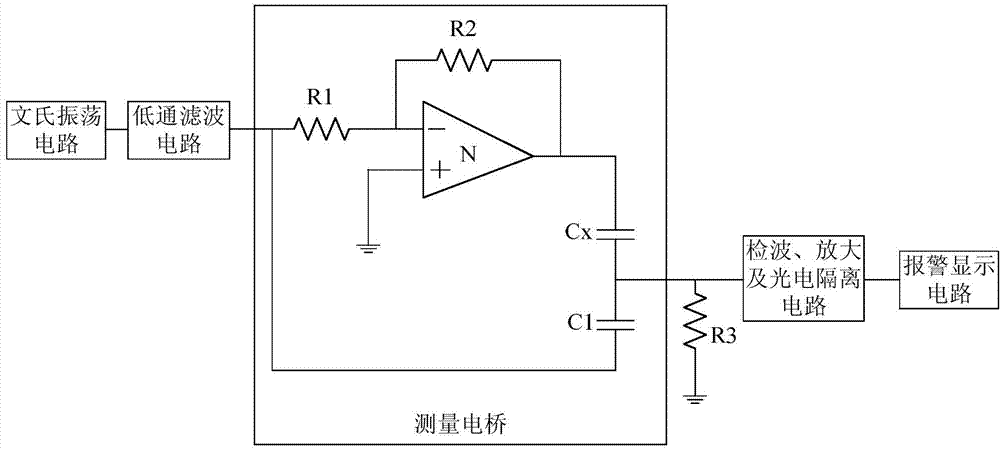

[0019] The following examples refer to Figure 1-2 .

[0020] The specific steps of the on-line detection method for oil and gas pipeline weld leakage of the present invention are as follows:

[0021] On the outer wall of the pipe-pipe welded joint of the oil and gas pipeline 4 that has undergone anti-corrosion treatment, first paint insulating paint, and according to the reinforcement height of the pipeline weld 2, wind and seal at the symmetrical positions on both sides of the outer wall of the oil and gas pipeline 4. Layer 3, and then wrap the stainless steel cladding 1 with a thickness of 0.1-0.5mm around the oil and gas pipeline 4 and then stick it on the sealing layer 3, and then use the capacitive energy storage spot welding process to complete the sealing connection of the stainless steel cladding 1. At this time, the outer wall of the oil and gas pipeline 4 and the inner wall of the stainless steel cladding 1 form the same core column capacitor Cx.

[0022] The Wien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com