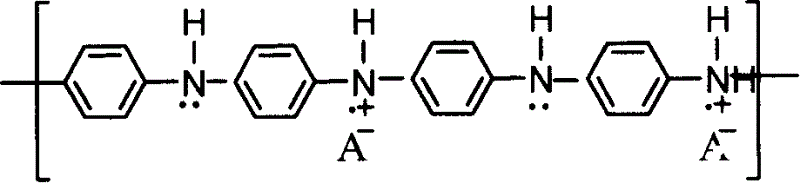

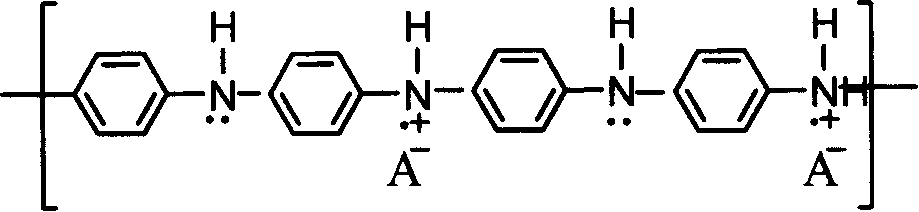

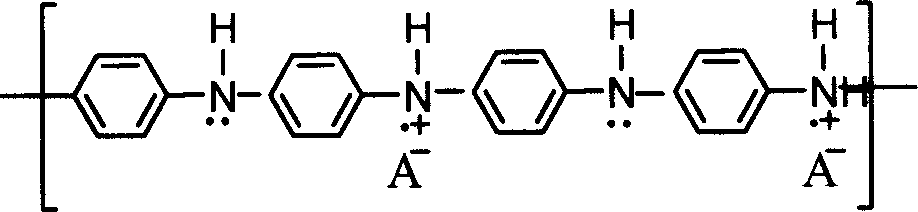

Phosphoric acid doped polyphenylamine phosphate priming paint and preparing process thereof

A technology of polyaniline phosphorus and polyaniline, which is applied in phosphoric acid-doped polyaniline phosphating primer and its preparation field, can solve the problems of large-area corrosion, volatilization and loss of hydrochloric acid dopant, etc., and achieves easy preparation, easy popularization, excellent Effect of coating film adhesion and antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation of phosphoric acid-doped polyaniline phosphating primer

[0036] The composition of the phosphoric acid-doped polyaniline phosphating primer is mentioned above, and the preparation of the primer has the following methods.

example 1

[0037] Example 1. The method for preparing polyaniline doped with phosphoric acid:

[0038] (1) Phosphoric acid doped polyaniline is first used to form phosphoric acid doped polyaniline, and then the conductive polymer of phosphoric acid doped polyaniline is combined with aluminum tripolyphosphate and phosphate antirust pigment, and then mixed with polyvinyl butyral Resin is made into, promptly obtains described primer.

[0039] Specific steps are as follows:

[0040] Dissolve the polyvinyl butyral resin into a 10% resin solution with a 3:1 mixed solvent of ethanol and butanol; take 130g of the 10% polyvinyl butyral solution, 1.95-8.45g of aluminum tripolyphosphate, phosphoric acid doped poly 0.13-6.5g of aniline, 2.6-5.9g of phosphate anti-rust pigment, 0.6-3.3g of talcum powder, 150ml of ethanol solvent, grind to make component A;

[0041] Take 10 g of 85% phosphoric acid, 8 g of distilled water, and 120 ml of a 3:1 mixed solvent of ethanol and butanol to form component B....

example 2

[0046] Example 2. The method of direct preparation with aniline:

[0047] Directly use small molecule aniline to form doped polyaniline through in-situ polymerization method at the same time of film formation, so that the conductive polymer of phosphoric acid doped polyaniline generated in situ can be combined with aluminum tripolyphosphate, phosphate antirust pigment and polyvinyl alcohol Butyral resin forms a coating of phosphoric acid doped polyaniline phosphating primer which has good rust protection properties.

[0048] The difference from Example 1 is that in component A, aniline is used instead of phosphoric acid to dope polyaniline, and a certain amount of chromic acid oxidant is added in component B. The chromic acid oxidizing agent includes: chromic acid, chromic anhydride, sodium dichromate, ammonium dichromate, potassium dichromate and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com