Component of laser processor and method for manufacturing corrosion resistant coating of channel thereof

A laser processing machine, corrosion-resistant technology, used in laser parts, lasers, optical components, etc., can solve the problems of brittle plastic hoses, pipe scattering, unsealing, etc., to achieve weight reduction, good anti-corrosion protection, reduce effect of numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

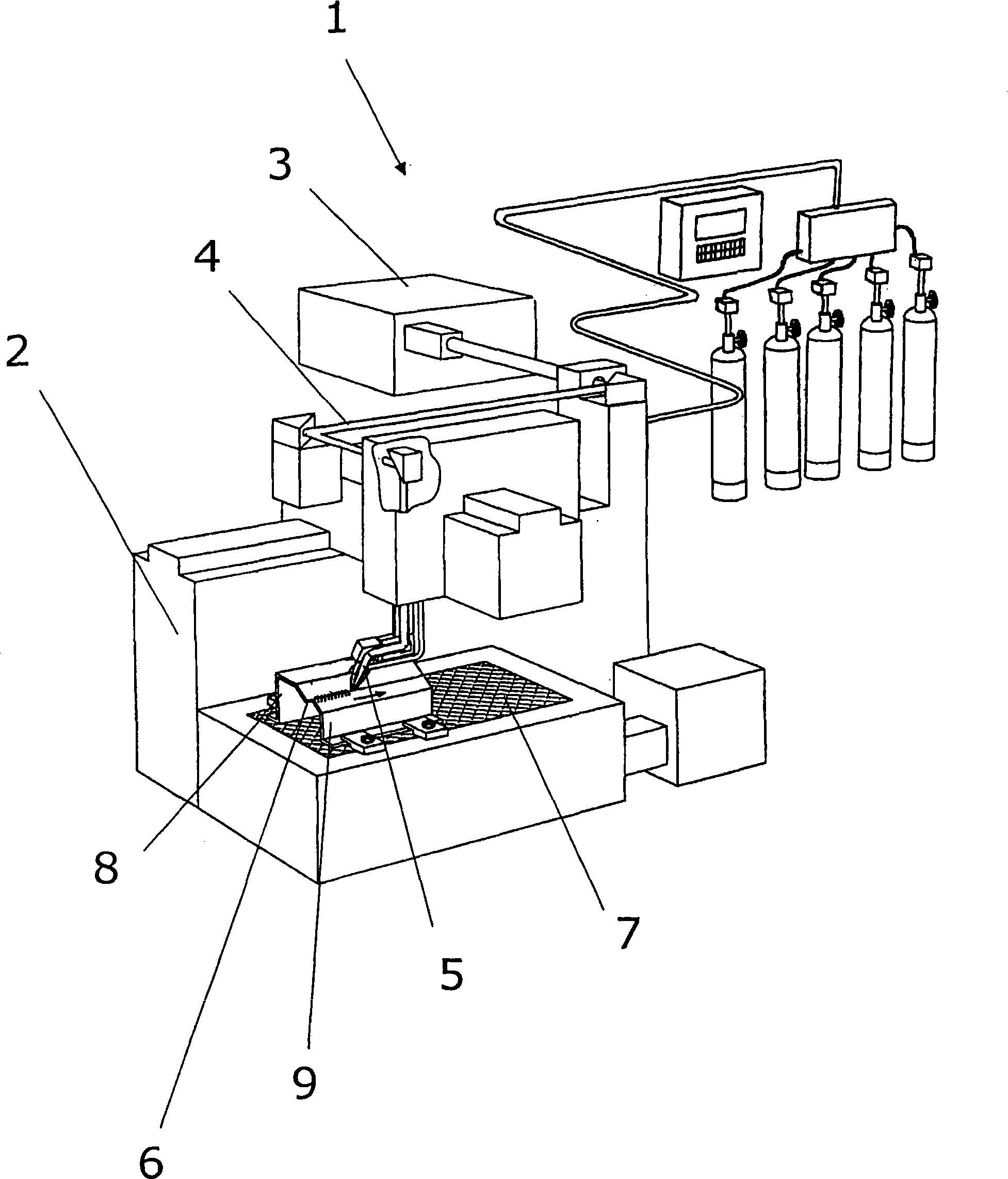

[0018] by figure 1 The structure of a laser processing machine 1 for laser welding can be seen. A machine frame 2 carries the movement unit of the machine and the beam guiding system. The beam guiding system has deflection mirrors for the laser beam 4 generated in the laser 3.

[0019] The laser welding head 5 with a deflecting mirror and a focusing mirror can move through two rotating shafts and can move in three directions, so as to be able to optimally process a weld 6 for joining two sets on one support Parts 8 and 9 on the seat 7. The part 8 and the part 9 are fixed by means of a clamp. To perform laser welding, processing gas, such as working gas or shielding gas (helium, argon, carbon dioxide, oxygen, nitrogen) can be supplied to the laser welding head 5, and the processing gas can be sucked away by a suction device.

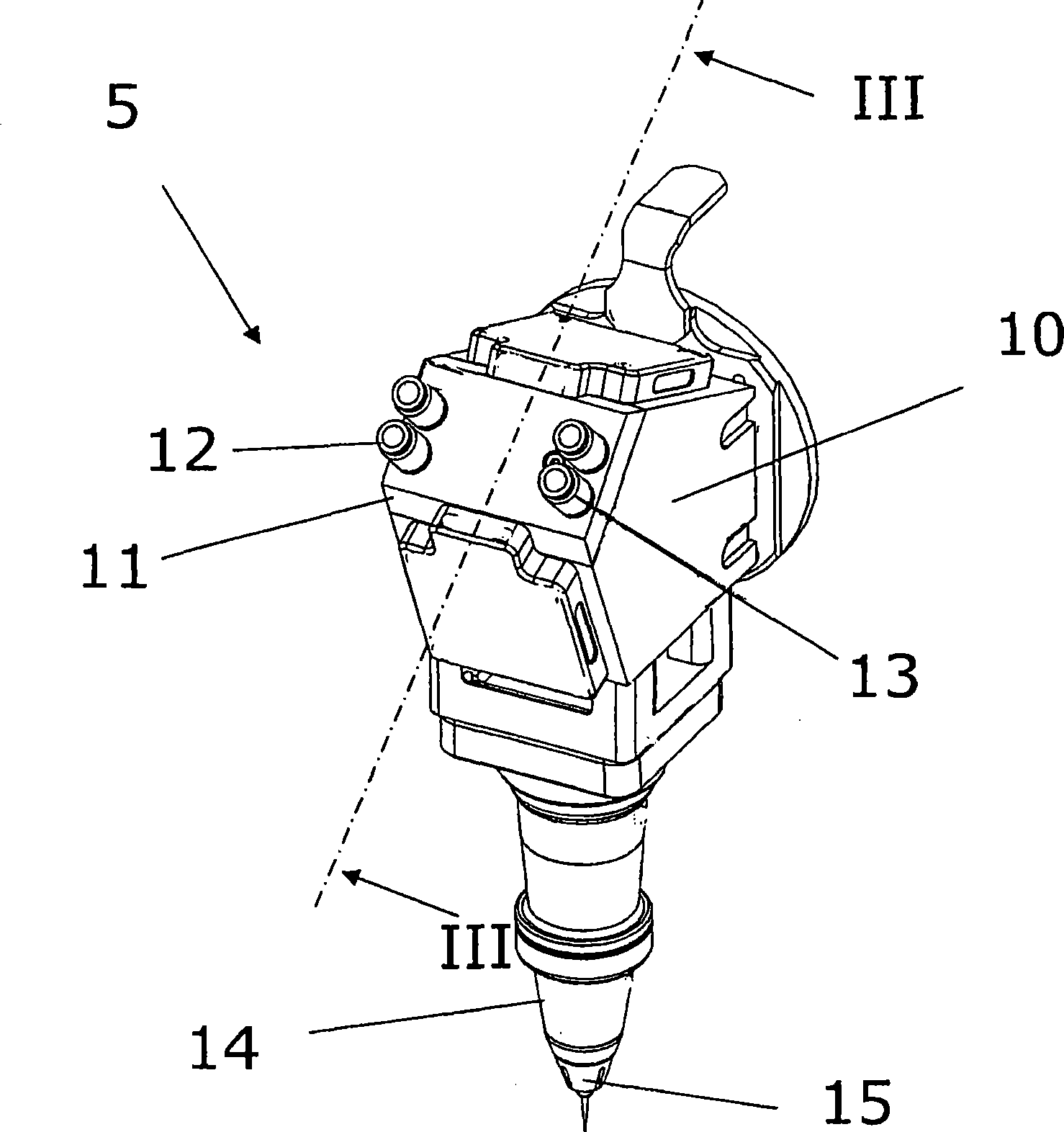

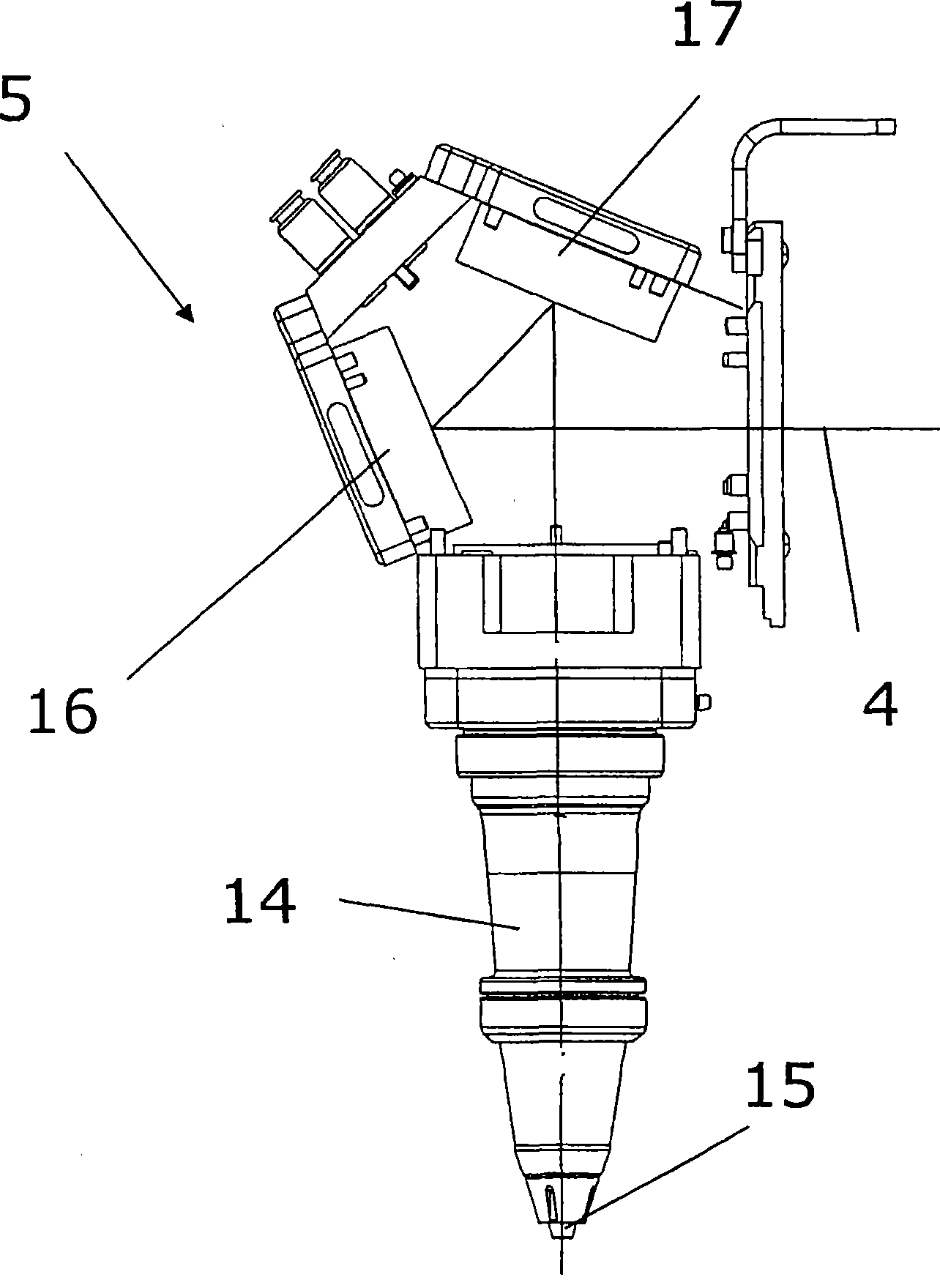

[0020] figure 2 The structure of the laser welding head 5 is involved. The structure of the laser welding head 5 is not described in detail here, because ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com