Detection circuit, preamplifier and eddy current sensor

A detection circuit and front-end device technology, which is applied in the direction of using electrical devices, instruments, and measuring devices, can solve problems such as temperature drift, measurement accuracy decline, and detection circuits that are easily affected by temperature, so as to improve output accuracy and improve The ability to resist temperature changes and reduce the effect of temperature on the signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

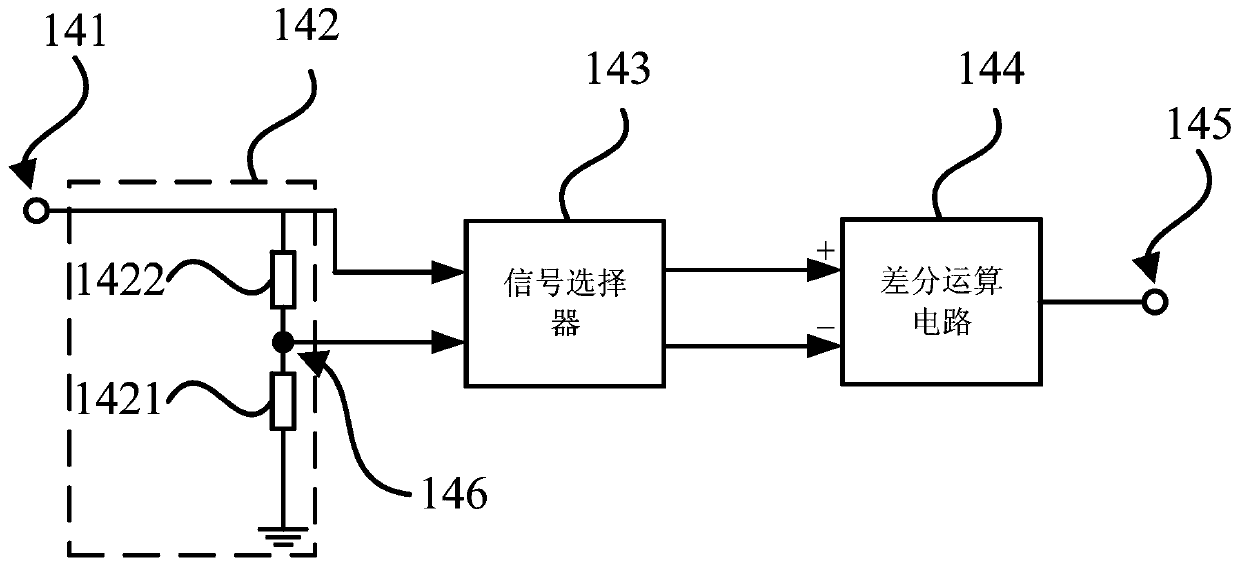

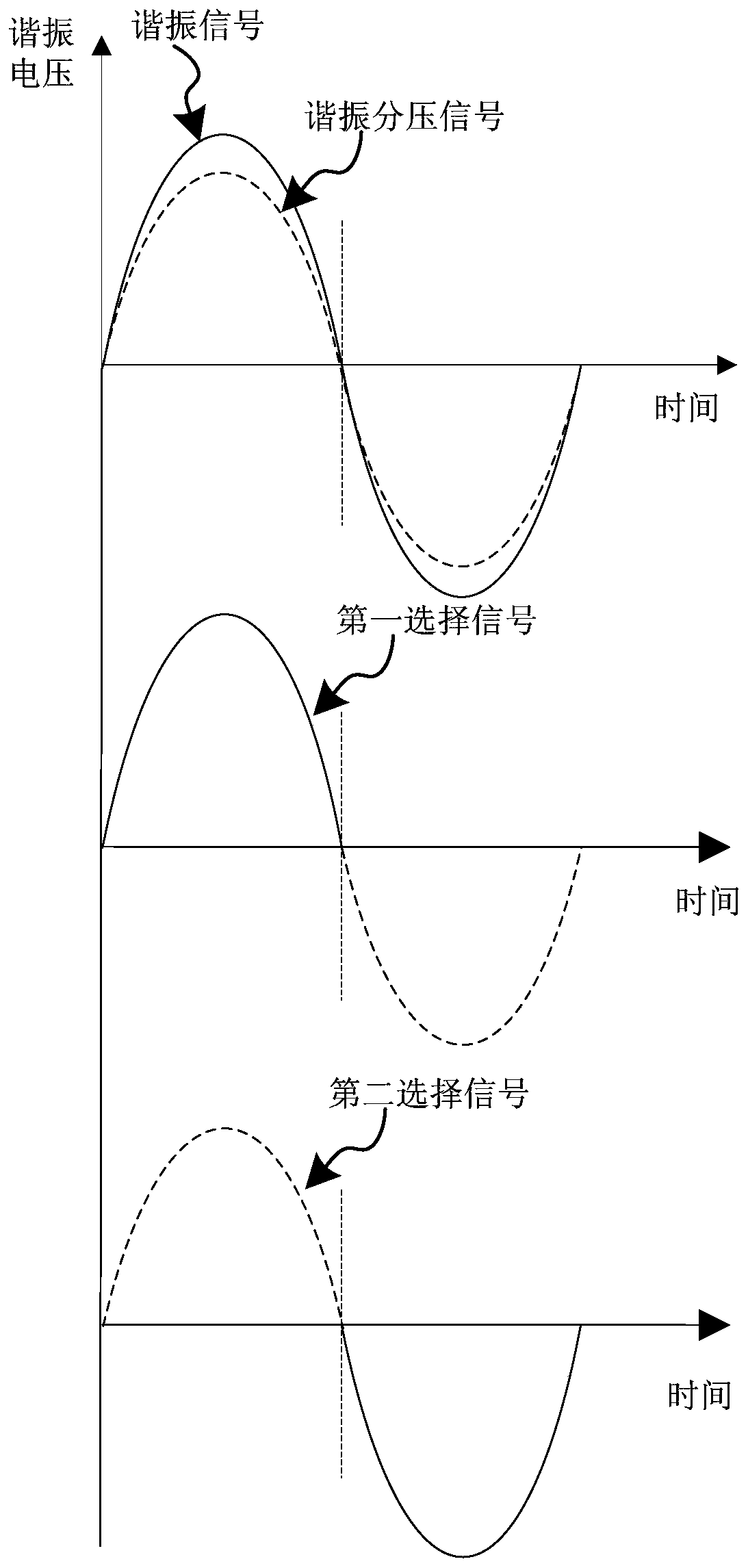

[0035] In order to solve the problem that the detection circuit in the prior art is easily affected by temperature, the embodiment of the present invention provides a detection circuit, please refer to figure 2 , which is a schematic diagram of a detection circuit provided in Embodiment 1 of the present invention.

[0036] This embodiment provides a detection circuit 14, including: an input terminal 141, used to receive the input resonance signal; a voltage divider circuit 142, connected to the input terminal 141, and a lead terminal 146 is set in the voltage divider circuit 142, which is used to adjust the resonance signal. After the signal is divided, the resonance voltage division signal is output; the signal selector 143 is connected to the input terminal 141 and the lead end 146 respectively, and is used to obtain the resonance signal and the resonance voltage division signal, and is used to divide the first half cycle signal of the resonance signal and the resonance volt...

Embodiment 2

[0046] This embodiment provides a front end, please refer to Figure 5 , which is a schematic diagram of a front-end device provided in Embodiment 2 of the present invention.

[0047] A pre-amplifier 1, including the detection circuit 14 provided by any embodiment of the present invention, also includes: an excitation source circuit 11, used to generate an excitation source signal; a voltage dividing resistor 12, connected in series with the excitation source circuit 11 and LC parallel resonance Between the circuits 13, it is used to divide the excitation source signal; the LC parallel resonant circuit 13 is connected with the voltage dividing resistor 12 and the detection circuit 14, and is used to receive the divided excitation source signal, and output the resonance signal to the detection circuit 14 ; The filter circuit 15 is connected to the detection circuit 14, receives the output signal of the detection circuit 14, and outputs the signal after filtering.

[0048] Spec...

Embodiment 3

[0053] This embodiment provides an eddy current sensor, please refer to Image 6 , which is a schematic diagram of an eddy current sensor provided in Embodiment 3 of the present invention.

[0054] An eddy current sensor includes the above-mentioned front-end device 1, and also includes a probe 3 and a cable 2, and the probe 3 is connected to the front-end device 1 through the cable 2.

[0055] In this technical solution, since the front-end device improves the ability to resist temperature changes, the signal processing and output of the front-end device are less affected by the temperature, so the eddy current sensor is also less affected by the temperature, which improves the eddy current The measurement accuracy of the sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com