Rice crust frying and oil filtering process method

A process method and crisper technology, which are applied in the direction of fat-containing food ingredients, food ingredients as thickeners, food ingredients as antioxidants, etc., can solve the problems of reducing the oil content of sweet potato chips, reducing the moisture content of food, and high hardness of finished products. Achieve good curative effect, reduce oil content, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

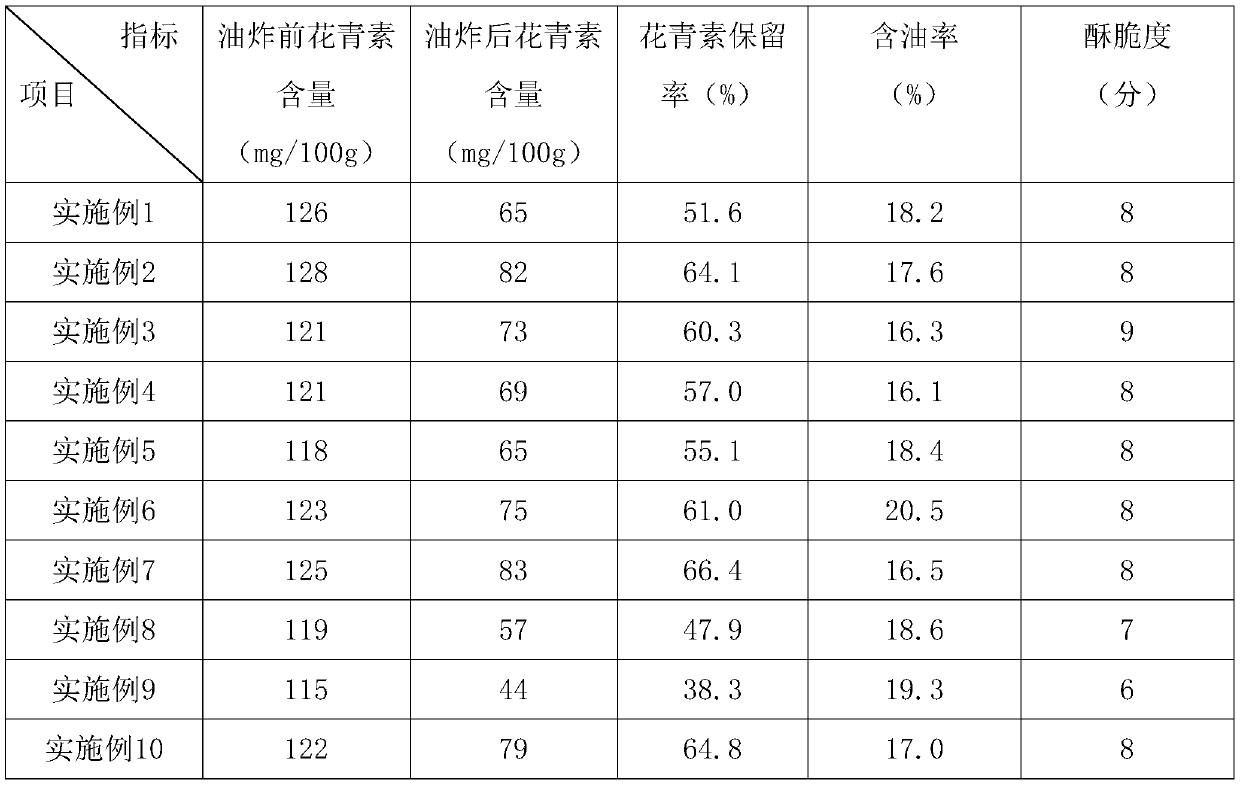

Embodiment 1

[0024] A technical method for crispy rice frying and oil filtering, comprising the following steps:

[0025] S1. Select high-quality glutinous rice, wash and cook to obtain rice grains;

[0026] S2. Select high-quality purple sweet potatoes, peel them, cut them into pieces, steam them and stir them to obtain purple sweet potato puree;

[0027] S3. Stir 100 parts of rice grains, 30 parts of purple sweet potato mash, 5 parts of table salt, 3 parts of white sugar, 6 parts of nutritional seasoning, 0.05 parts of phytic acid, 2 parts of sodium caseinate, and 1 part of sorbitol, and knead it into Thin slices of glutinous rice and purple sweet potato are obtained after pressing and slicing after the dough;

[0028] S4. Spray a film-forming agent on the surface of the glutinous rice and purple potato slices. The film-forming agent includes 10 parts by mass of glucomannan, 5 parts of sodium alginate, and 0.5 part of cysteine. After standing for 10 minutes, put the glutinous rice and p...

Embodiment 2

[0031] A technical method for crispy rice frying and oil filtering, comprising the following steps:

[0032] S1. Select high-quality glutinous rice, wash and cook to obtain rice grains;

[0033] S2. Select high-quality purple sweet potatoes, peel them, cut them into pieces, steam them and stir them to obtain purple sweet potato puree;

[0034] S3. Stir 100 parts of rice grains, 50 parts of purple sweet potato mash, 3 parts of table salt, 8 parts of white sugar, 2 parts of nutritional seasoning, 0.5 parts of phytic acid, 0.5 parts of sodium caseinate, and 3 parts of sorbitol, and knead it into Thin slices of glutinous rice and purple sweet potato are obtained after pressing and slicing after the dough;

[0035] S4. Spray a film-forming agent on the surface of the glutinous rice and purple sweet potato slices. The film-forming agent includes 5 parts by mass of glucomannan, 10 parts of sodium alginate, and 0.1 part of cysteine. After standing for 30 minutes, put the glutinous ri...

Embodiment 3

[0038] A technical method for crispy rice frying and oil filtering, comprising the following steps:

[0039] S1. Select high-quality glutinous rice, wash and cook to obtain rice grains;

[0040] S2. Select high-quality purple sweet potatoes, peel them, cut them into pieces, steam them and stir them to obtain purple sweet potato puree;

[0041] S3. Stir 100 parts of rice grains, 40 parts of purple sweet potato mash, 4 parts of table salt, 6 parts of white sugar, 4 parts of nutritional seasoning, 0.3 parts of phytic acid, 1.5 parts of sodium caseinate, and 2 parts of sorbitol, and knead it into Thin slices of glutinous rice and purple sweet potato are obtained after pressing and slicing after the dough;

[0042] S4. Spray a film-forming agent on the surface of the glutinous rice and purple potato slices. The film-forming agent includes 8 parts by mass of glucomannan, 8 parts of sodium alginate, and 0.3 part of cysteine. After standing for 20 minutes, put the glutinous rice and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com