Method for processing soy sauce stewed beef by ultrasonic assisted boiling

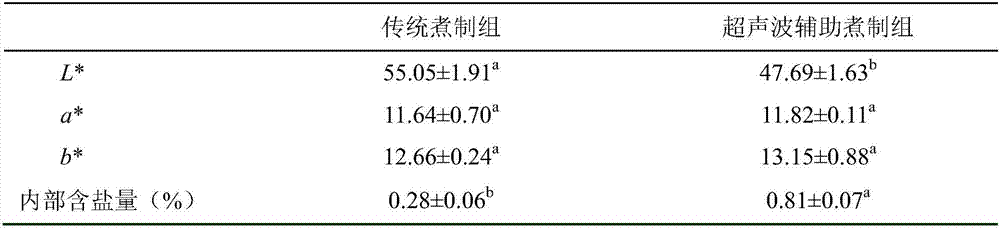

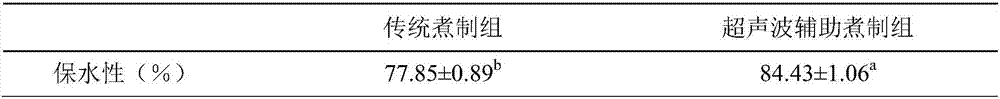

A technology of braised beef in sauce and ultrasonic wave, which is applied in the field of cooking and braised beef in sauce and assisted cooking and processing of braised sauce by ultrasonic wave, can solve the problem of low yield of braised meat products, poor penetration effect of braised soup, lack of tenderization technology, etc. The problem is to shorten the cooking time, improve the water retention of the product, and improve the quality of the meat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

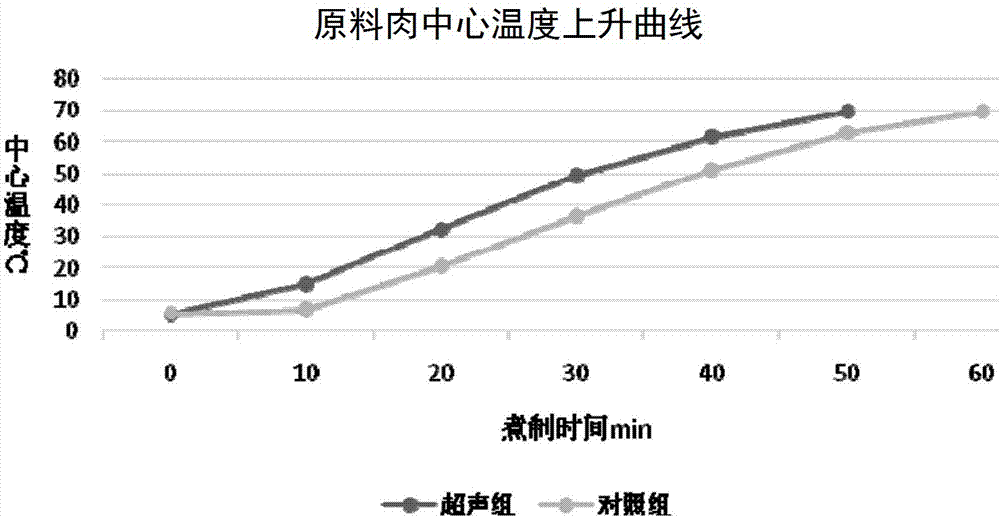

[0022] Clean the fresh beef rump meat with blood on the surface, remove visible fat and fascia, divide it into 8×8×8cm uniform squares, and immerse it in the pickling solution (2% (w / w) salt) according to the meat liquid volume ratio of 1:3 , 0.5% (w / w) monosodium glutamate, 0.4% (w / w) compound phosphate, 2% (w / w) sugar, and the balance is water), marinated at 4°C for 24h; Boil after preparation, add other seasonings during the boiling process (10kg water, 15g star anise, 5g bay leaf, 3g angelica, 1g clove, 3g pepper, 8g cinnamon, 3g white buckle, 3g tangerine peel, 2g grass fruit, 3g kaempferia , amomum 1g, salt 200g, sugar 150g, monosodium glutamate 50g, light soy sauce 200g, acetaminophen maltol 5g), boiled into stewed soup; put the above-mentioned stewed beef raw materials into the stewed stewed soup During the cooking process, 0W and 800W power ultrasonic waves (frequency 20kHz) were used to assist cooking, and the central temperature was controlled at 70±2°C for 120 minu...

Embodiment 2

[0025] Adopt the supersonic wave (frequency is 25kHz) of 300W power to assist cooking in the boiling process, other conditions are with embodiment 1.

Embodiment 3

[0027] Adopt the supersonic wave (frequency is 23kHz) of 500W power to assist cooking in the boiling process, other conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com