Poultry freezing and fresh-keeping method

A technology of freezing preservation and cryoprotective liquid, which is applied in food freezing, meat/fish preservation through freezing/cooling, meat/fish preservation with chemicals, etc. It can solve the problems of loose poultry meat tissue, loss of nutritional components, and reduction of freshness, etc. problem, achieve the effects of reducing the loss rate of juice, preventing growth and swelling, and inhibiting lipid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

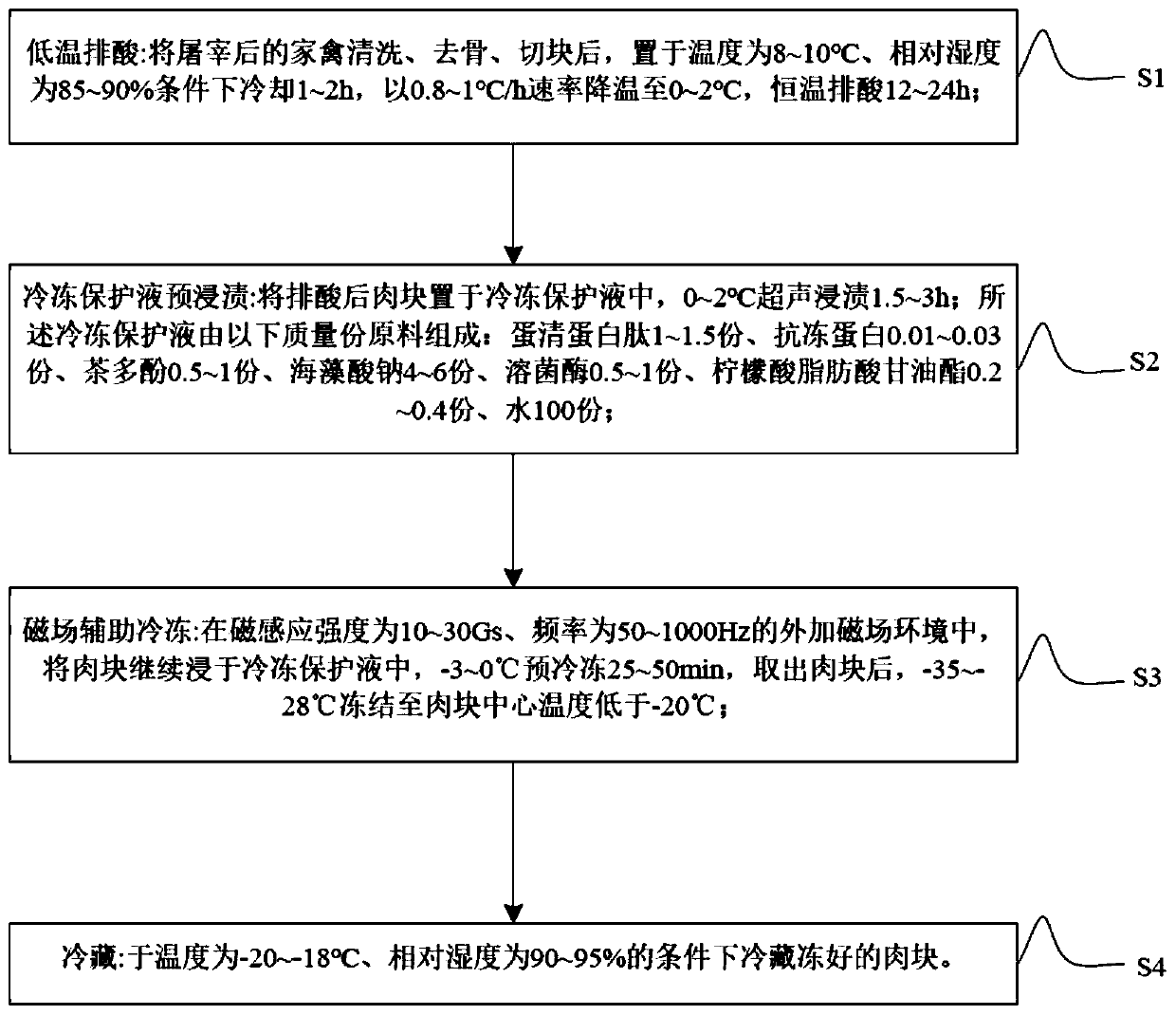

Method used

Image

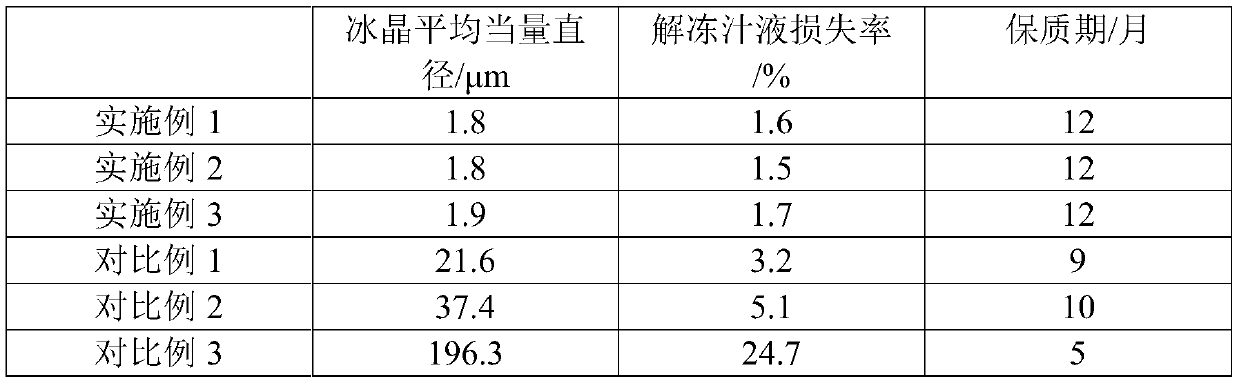

Examples

Embodiment 1

[0024] A method for freezing and keeping poultry fresh, comprising the following steps:

[0025] S1: Low-temperature deacidification: Wash the slaughtered chickens, remove the bones, cut them into meat pieces with a size of 4.5 cm×4 cm, and cool them for 1 hour at a temperature of 8°C and a relative humidity of 85%. The temperature is lowered to 2°C at a rate of h, and the acid is discharged at a constant temperature for 12 hours;

[0026] S2: Pre-soaking in cryoprotectant solution: place the meat pieces after deacidification in cryoprotectant solution, and ultrasonically immerse at 2°C for 1.5h; the ultrasonic power is 300W, and the frequency is 25KHz;

[0027] The cryoprotectant solution is composed of the following raw materials in parts by mass: 1 part of egg white protein peptide, 0.01 part of antifreeze protein, 0.5 part of tea polyphenol, 4 parts of sodium alginate, 0.5 part of lysozyme, citric acid fatty acid glycerin with an HLB value of 5 0.2 parts of ester, 100 par...

Embodiment 2

[0031] A method for freezing and keeping poultry fresh, comprising the following steps:

[0032] S1: Low-temperature deacidification: Wash the slaughtered chickens, remove the bones, cut them into meat pieces with a size of 4.5 cm×4 cm, and cool them for 1.5 hours at a temperature of 10°C and a relative humidity of 90%. Cool down to 1°C at a rate of / h, and discharge acid at constant temperature for 18 hours;

[0033] S2: Pre-soaking in cryoprotectant solution: place the meat pieces after deacidification in cryoprotectant solution, and ultrasonically immerse at 1°C for 2 hours; the ultrasonic power is 350W, and the frequency is 30KHz;

[0034] The cryoprotectant solution is composed of the following raw materials in parts by mass: 1.2 parts of egg white protein peptide, 0.02 part of antifreeze protein, 0.8 part of tea polyphenol, 5 parts of sodium alginate, 0.8 part of lysozyme, citric acid fatty acid glycerin with an HLB value of 5 0.3 parts of ester, 100 parts of water;

...

Embodiment 3

[0038] A method for freezing and keeping poultry fresh, comprising the following steps:

[0039] S1: Low-temperature deacidification: Wash the slaughtered duck, remove the bones, cut it into meat pieces with a size of 5cm×4.5cm, and cool it for 2 hours at a temperature of 8°C and a relative humidity of 85%. h The temperature is lowered to 0°C, and the acid is discharged at a constant temperature for 18 hours;

[0040] S2: Pre-soaking in cryoprotectant solution: place the meat pieces after deacidification in cryoprotectant solution, and ultrasonically immerse at 0°C for 2 hours; the ultrasonic power is 400W, and the frequency is 35KHz;

[0041] The cryoprotectant solution is composed of the following raw materials in parts by mass: 1.5 parts of egg white protein peptide, 0.03 part of antifreeze protein, 1 part of tea polyphenol, 6 parts of sodium alginate, 1 part of lysozyme, citric acid fatty acid glycerin with an HLB value of 5 0.4 parts of ester, 100 parts of water;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com