Rust-proof gate valve with high sealing performance

A technology of high sealing and gate valves, applied in shaft sealing, valve details, valve devices, etc., can solve the problems of poor sealing of gate valves, and achieve the effect of improving sealing performance, improving overall mechanical strength, and not easy to slide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

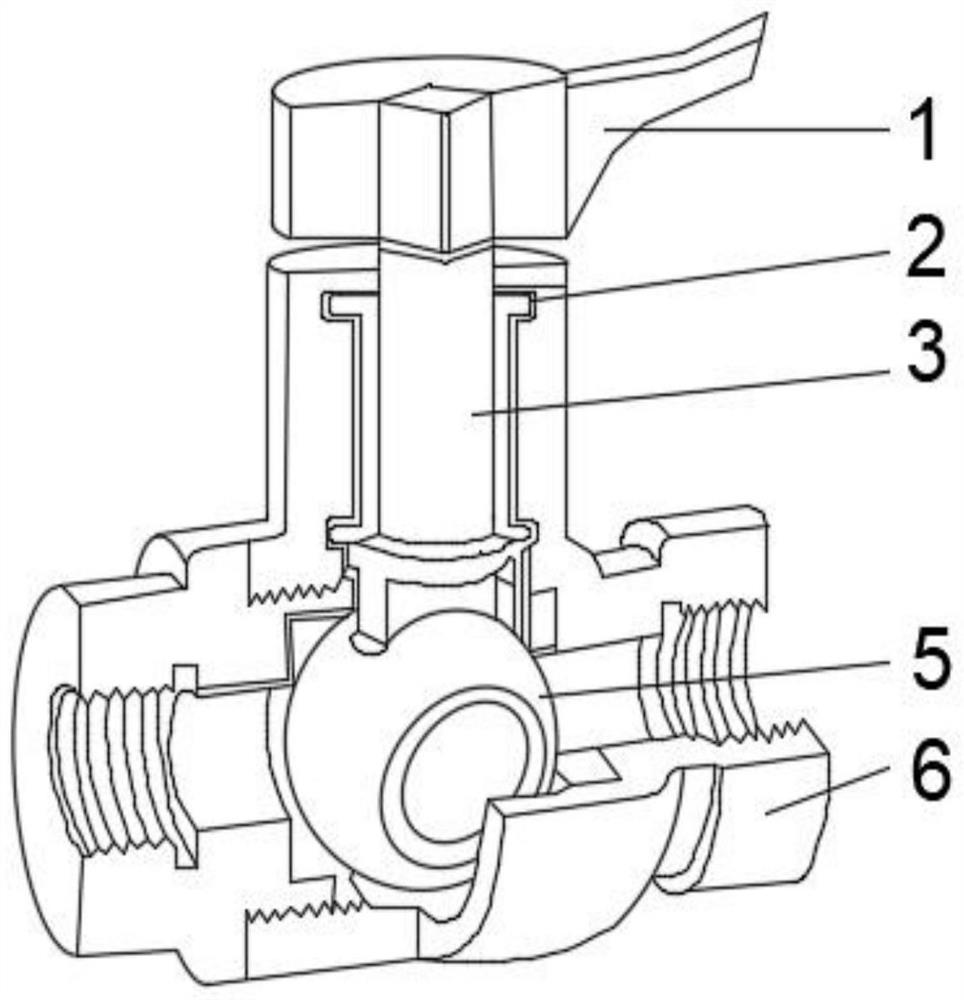

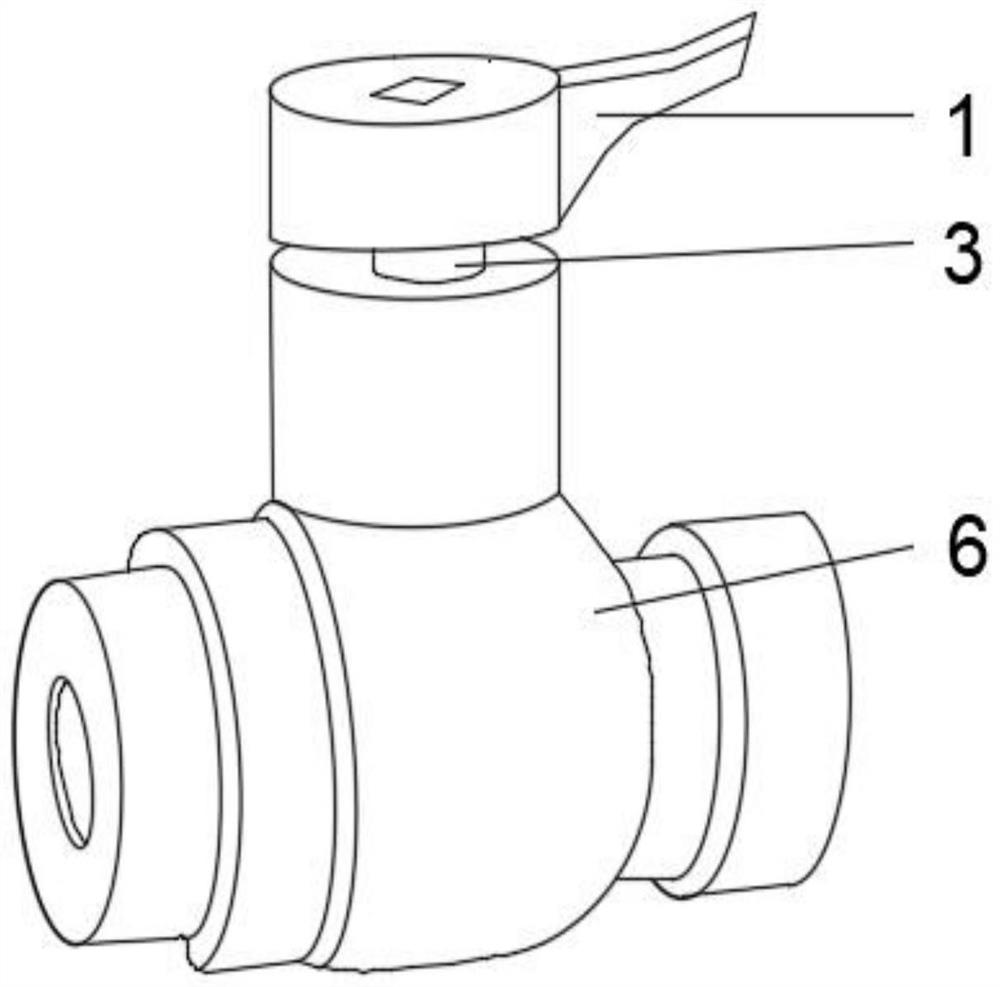

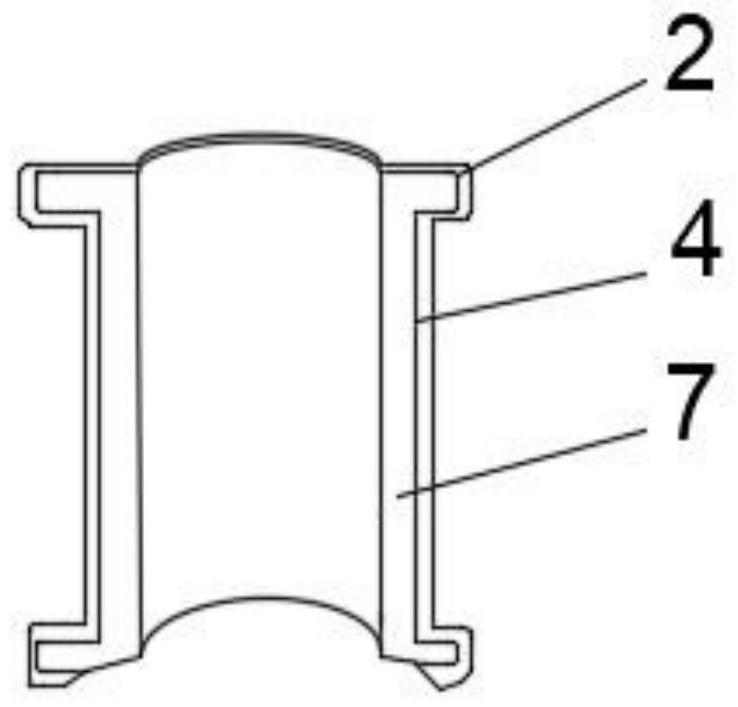

[0036] according to Figure 1-3 As shown, this embodiment is a high-tight anti-rust gate valve, including a handle 1, a valve stem 3 and a valve body 6, the valve stem 3 is installed in the valve body 6, and the top of the valve stem 3 runs through the valve body 6, A handle 1 is installed on the top of the valve stem 3, a ball 5 is installed on the bottom of the valve stem 3, and a protective layer 2 is arranged between the valve stem 3 and the valve body 6, and the protective layer 2 includes a sealing layer 7 and an antirust layer 4;

[0037] Wherein the preparation steps of sealing layer 7 are as follows:

[0038]S1: Thinly pass butyl rubber on the open mill for 4 times, add zinc oxide, stearic acid, naphthenic oil and sulfur, mix completely on the open mill, widen the roller distance to press out the rubber sheet, and obtain the butyl rubber mixture. rubber mixing;

[0039] S2: pass the natural rubber on the mill for 3 times, add zinc oxide, stearic acid, anti-aging age...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] Wherein the preparation steps of sealing layer 7 are as follows:

[0048] S1: Thinly pass butyl rubber on the open mill for 4 times, add zinc oxide, stearic acid, naphthenic oil and sulfur, mix completely on the open mill, widen the roller distance to press out the rubber sheet, and obtain the butyl rubber mixture. rubber mixing;

[0049] S2: pass the natural rubber on the mill for 4 times, add zinc oxide, stearic acid, anti-aging agent, sulfur, mix evenly, and produce a sheet to obtain a natural rubber compound;

[0050] S3: Mix natural rubber compound and butyl rubber compound, blend and knead on the open mill at room temperature for 15 minutes, park for 24 hours, and carry out crosslinking in a flat vulcanizer. The set temperature during vulcanization is 155 ° C. The pressure is 20MPa, and the time is 100 minutes to obtain the sealing layer 7;

[0051] Wherein the preparation steps of antirust la...

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is:

[0057] Wherein the preparation steps of sealing layer 7 are as follows:

[0058] S1: Thinly pass butyl rubber on the open mill for 3 times, add zinc oxide, stearic acid, naphthenic oil and sulfur, mix completely on the open mill, widen the roller distance to press out the rubber sheet, and obtain the butyl rubber compound. rubber mixing;

[0059] S2: pass the natural rubber on the mill for 3 times, add zinc oxide, stearic acid, anti-aging agent, sulfur, mix evenly, and release the flakes to obtain the natural rubber compound;

[0060] S3: Mix the natural rubber compound and butyl rubber compound, blend and knead on the open mill at room temperature for 15 minutes, park for 24 hours, and carry out crosslinking in a flat vulcanizer. The temperature set during vulcanization is 145-155°C , using a pressure of 20 MPa and a time of 100 minutes to obtain the sealing layer 7;

[0061] Wherein the preparation steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Charge transfer resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com