Dyeing process of pure cotton fabric

A pure cotton fabric and process technology, applied in the field of high fixation rate salt-free dyeing process, can solve the problems of large sewage discharge, high equipment price, hidden danger of equipment safety, etc., and achieves harmless environment and human health, easy recovery and recycling The effect of utilizing and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] 1. Fabric dyeing pretreatment

[0035] 10g pure cotton fabric with 110g / L Na 2 CO 3 After full swelling, control the squeeze rate to about 180%, and wait for dyeing;

[0036] 2. Preparation of reactive dye / D5 suspension system

[0037]Weigh 0.2g of Active Dairy Cotton Brilliant Red K-4BL, grind it in a ball mill for 2 hours, add 1.8g of ethanol, and after grinding for 1 hour, take out the mixture of dye and ethanol, add 500g of D5, and shear at high speed for 5 minutes. The rotation speed is 600r / min, and the dye / D5 suspension system is ready for use;

[0038] 3. Fabric dyeing

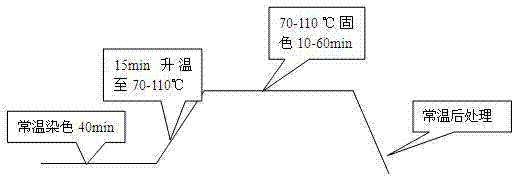

[0039] Take the pretreated pure cotton fabric and immerse it in the dyeing bath of dye / D5 suspension prepared in step 2, dye at room temperature for 40 minutes, then slowly heat up to 70-110°C within 15 minutes, and solidify at 70-110°C Dye for 10-60 minutes, and finally lower the temperature to room temperature to complete the dyeing. Its process curve is as figure 1 shown.

[0040] R...

example 2

[0050] 1. Fabric dyeing pretreatment

[0051] 10g pure cotton fabric with 130g / L Na 2 CO 3 After full swelling, control the squeeze rate to about 180%, and wait for dyeing;

[0052] 2. Preparation of reactive dye / D5 suspension system

[0053] Weigh 0.4g of reactive dark blue M-2GE (C.I. reactive blue 194) and grind it in a ball mill for 2 hours, add 3.6g of ethanol, after grinding for 1 hour, take out the mixture of dye and ethanol, add 500g of D5, high-speed shear for 5min, high-speed shear The speed of cutting is 600r / min, and the dye / D5 suspension system is ready for use;

[0054] 3. Fabric dyeing

[0055] Take the pretreated pure cotton fabric and immerse it in the dyeing bath of the dye / D5 suspension prepared in step 2, dye it at room temperature for 40 minutes, then slowly raise the temperature to 40-80°C within 15 minutes, and solidify at 40-80°C. Dye for 10-60 minutes, and finally lower the temperature to room temperature to complete the dyeing.

[0056] Reactiv...

example 3

[0066] 1. Fabric dyeing pretreatment

[0067] 10g pure cotton fabric with 110 g / L Na 2 CO 3 After full swelling, control the squeeze rate to about 180%, and wait for dyeing;

[0068] 2. Preparation of reactive dye / D5 suspension system

[0069] Weigh 0.8g of active Dai Li cotton bright red K-4BL, grind it in a ball mill for 2 hours, add 7.2g of ethanol, after grinding for 1 hour, take out the mixture of dye and ethanol, add 500g of D5, and shear at high speed for 5min. The rotation speed is 600r / min, and the dye / D5 suspension system is ready for use;

[0070] 3. Fabric dyeing

[0071] Take the pretreated pure cotton fabric and immerse it in the dyeing bath of the dye / D5 suspension prepared in step 2, dye at room temperature for 40 minutes, then slowly heat up to 70-110°C within 15 minutes, and fix the color at 70-110°C for 10 minutes -60min Finally, lower the temperature to room temperature to complete the dyeing.

[0072] Reactive dye dyeing experimental process formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com