Processing method and device for rice bran preservation

A processing device and processing method technology, which is applied in edible seed preservation, chemical instruments and methods, food preservation, etc., can solve the problems of high preservation cost and complicated process, and achieve the goals of reducing corruption, ensuring uniformity, and eliminating sharp corner effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

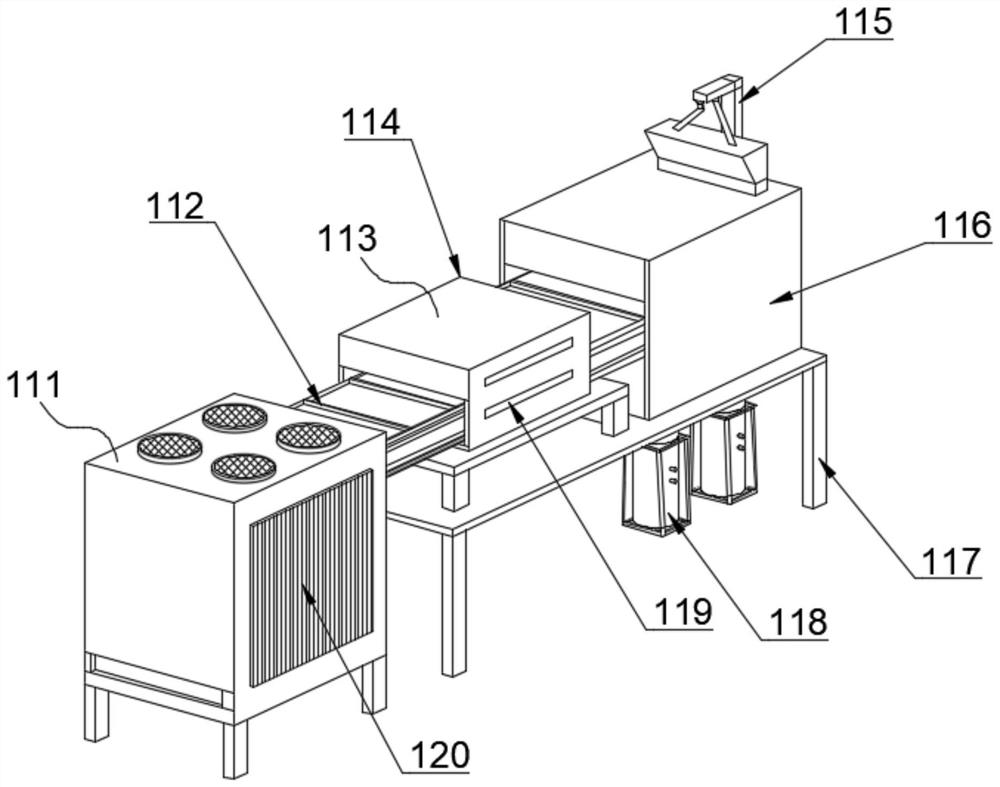

[0029] see Figure 1-5 As shown, the present embodiment carries out fresh-keeping processing to japonica rice bran, and concrete processing process is as follows:

[0030]Screening: The fresh rice bran after the polished rice is quantitatively transported into the screening mechanism 500 through the feeding hoist 115, and large-particle impurities such as unground rice husks and doped straws are screened out, and fine powder and ash are screened. In addition, the rice bran suitable for production is obtained;

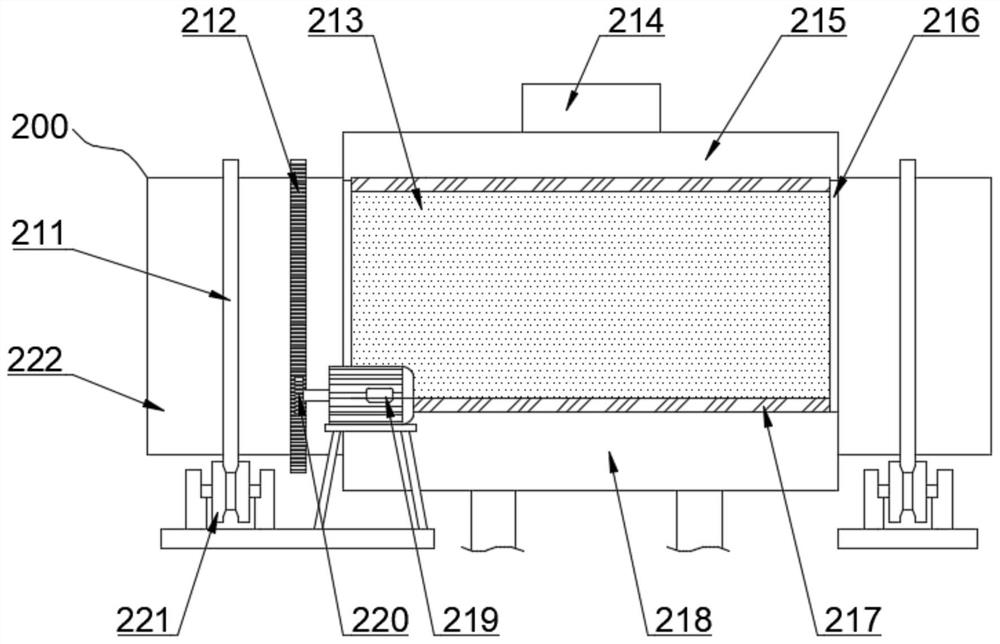

[0031] Enzyme elimination by steaming: transport the sieved rice bran into the autoclaving mechanism 200, set the steam pressure to 0.5MPa, adjust the speed of the first motor 219 so that the steaming time of the rice bran is 10min, and the autoclaving cylinder 222 The lipase on the surface of the rice bran is inactivated;

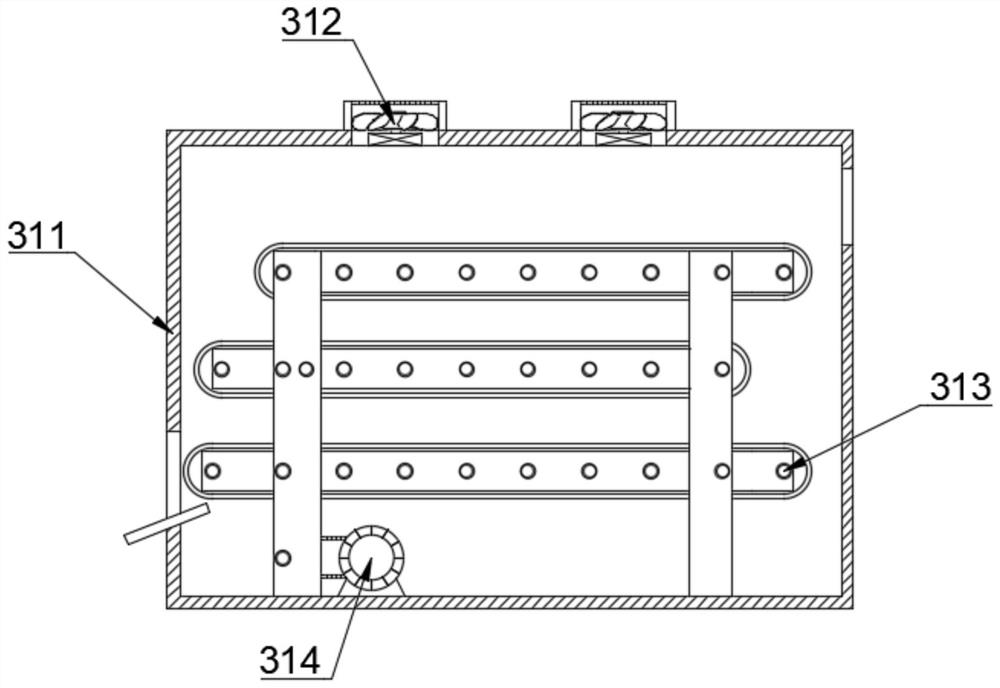

[0032] Radio frequency enzyme elimination: transport the autoclaved rice bran into the radio frequency processing mechanism 113, the power of the...

Embodiment 2

[0035] see Figure 1-5 As shown, the present embodiment carries out fresh-keeping processing to japonica rice bran, and concrete processing process is as follows:

[0036] Screening: The fresh rice bran after the polished rice is quantitatively transported into the screening mechanism 500 through the feeding hoist 115, and large-particle impurities such as unground rice husks and doped straws are screened out, and fine powder and ash are screened. In addition, the rice bran suitable for production is obtained;

[0037] Enzyme inactivation by steam: Transport the sieved rice bran into the autoclaving mechanism 200, set the pressure of the water vapor to 0.6 MPa, adjust the speed of the first motor 219 so that the steaming time of the rice bran is 12 minutes, and the steam in the autoclave 222 The lipase on the surface of the rice bran is inactivated;

[0038] Radio frequency deactivation: the steamed rice bran is transported into the radio frequency processing mechanism 113, ...

Embodiment 3

[0041] see Figure 1-5 As shown, the present embodiment carries out fresh-keeping processing to japonica rice bran, and concrete processing process is as follows:

[0042] Screening: The fresh rice bran after the polished rice is quantitatively transported into the screening mechanism 500 through the feeding hoist 115, and large-particle impurities such as unground rice husks and doped straws are screened out, and fine powder and ash are screened. In addition, the rice bran suitable for production is obtained;

[0043] Enzyme elimination by steaming: transport the sieved rice bran into the autoclaving mechanism 200, set the pressure of the steam to 0.8MPa, adjust the speed of the first motor 219 so that the steaming time of the rice bran is 15min, and the autoclaving cylinder 222 The lipase on the surface of the rice bran is inactivated;

[0044] Radio frequency deactivation: the steamed rice bran is transported into the radio frequency processing mechanism 113, the power of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com