Method for manufacturing frozen microwave instant food

A manufacturing method and food technology, which are applied in the manufacturing field of frozen microwave ready-to-eat food, can solve the problems of affecting the nutritional flavor of meat, become hard granules, and cannot be swallowed, so as to increase additional nutritional value, inhibit aging, and improve dry taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

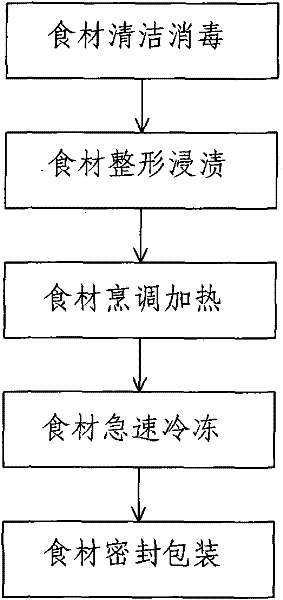

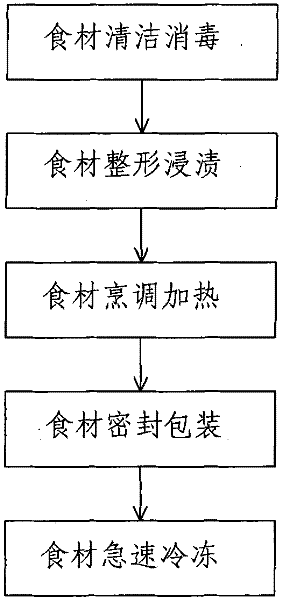

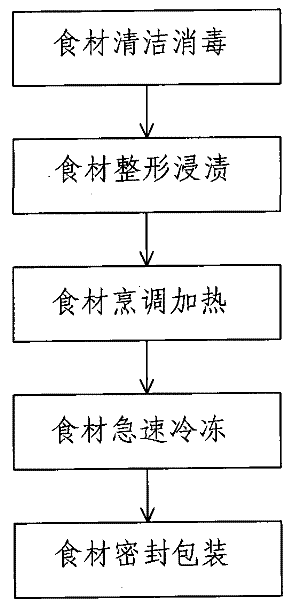

[0024] Please see attached figure 1 , 2 As shown, the manufacturing method of the frozen microwave instant food of the present invention mainly comprises the following steps:

[0025] a. Clean and sterilize ingredients (for example, raw meat, vegetables and fruits, and rice). Meat can be beaten raw meat or use "trehalose and polysaccharide (or colloid, phospholipid, starch, compound polylactic acid, commercial food thickener, commercial food adhesive) aqueous solution" as the base, add fruit , yogurt, probiotics, or one or more of enzymes to improve and soften the meat, making the meat soft and easy to chew.

[0026] b. Shaping and dipping the ingredients. Washing and shaping of vegetab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com