Gypsum panel with cavities and dry-method production method thereof

A technology of hollow slats and production methods, which is applied in the field of building walls, can solve the problems of high water content, achieve low free water content, reduce production costs and cycles, and achieve low water-to-paste ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

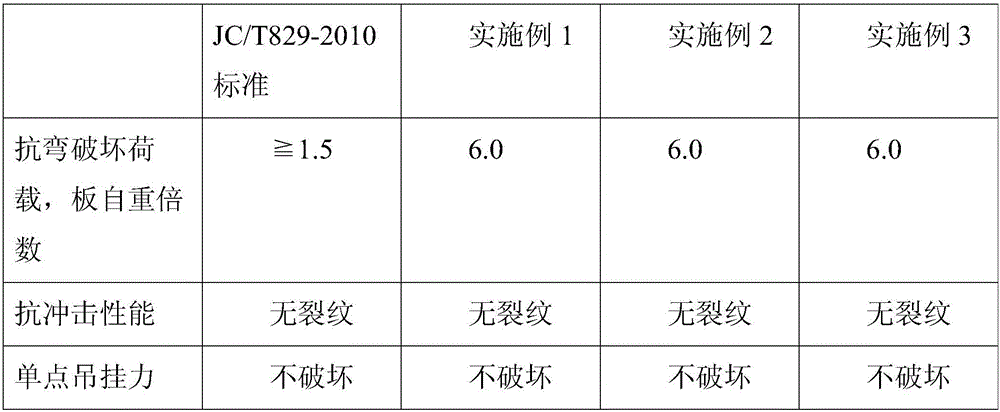

Embodiment 1

[0020] A gypsum hollow slab made of the following raw materials in parts by weight:

[0021] A total of 80 parts of desulfurized gypsum and titanium gypsum, 2 parts of XK dry process additive, 20 parts of expanded perlite and water, wherein the mass ratio of water: the total weight of desulfurized gypsum and titanium gypsum is 0.3:1.

[0022] A dry method for producing gypsum hollow slats, comprising the following steps:

[0023] 1) Weigh desulfurization gypsum and titanium gypsum, XK dry process additive and water, mix and stir, then add expanded perlite, and mix and stir evenly;

[0024] 2) The mixture obtained in step 1) is injected into the intermittent hydraulic extrusion molding gypsum hollow slab molding equipment, and hydraulic extrusion molding is completed.

Embodiment 2

[0026] A total of 90 parts of fluorogypsum and phosphogypsum, 1 part of XK dry process additive, 15 parts of vitrified microbeads and water, wherein the mass ratio of water: the total weight of fluorogypsum and phosphogypsum is 0.33:1.

[0027] A dry method for producing gypsum hollow slats, comprising the following steps:

[0028] 1) Weigh fluorogypsum, phosphogypsum, XK dry additive and water, mix and stir, then add vitrified microbeads, mix and stir evenly;

[0029] 2) The mixture obtained in step 1) is injected into the intermittent hydraulic extrusion molding gypsum hollow slab molding equipment, and hydraulic extrusion molding is completed.

Embodiment 3

[0031] A gypsum hollow slab made of the following raw materials in parts by weight:

[0032] A total of 85 parts of titanium gypsum and fluorine gypsum, 2 parts of XK dry process additive, a total of 18 parts of vitrified microbeads and saw foam ash, and water, wherein the mass ratio of water: total weight of titanium gypsum and fluorine gypsum is 0.32:1.

[0033] A dry method for producing gypsum hollow slats, comprising the following steps:

[0034] 1) Weigh titanium gypsum, fluorogypsum, XK dry process additive and water, mix and stir, then add vitrified beads and saw foam ash, mix and stir evenly;

[0035] 2) The mixture obtained in step 1) is injected into the intermittent hydraulic extrusion molding gypsum hollow slab molding equipment, and hydraulic extrusion molding is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com