A device for improving clinker phase composition during ball milling

A technology of ball milling and clinker, which is applied in the field of devices to improve the composition of clinker phase, can solve problems such as the influence of gypsum board bonding and strength, the influence of gypsum board production process, and the increase in water demand, so as to reduce energy consumption and prevent quality accidents , Reduce the effect of water paste ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

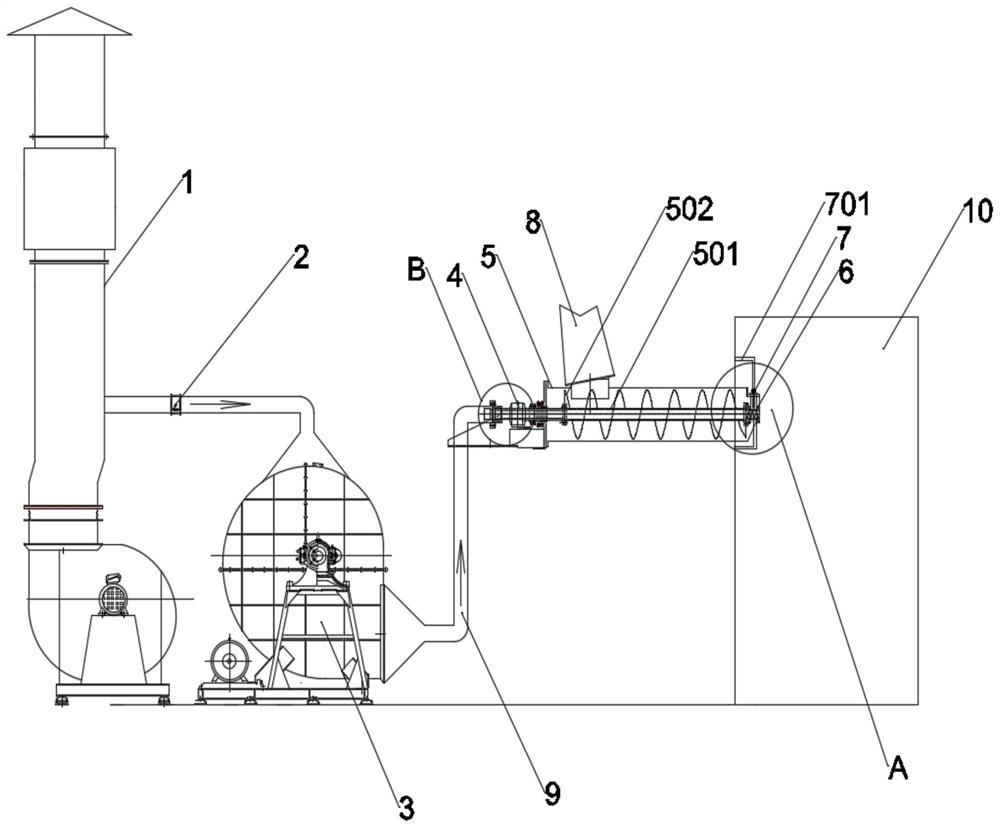

[0037] Such as figure 1 As shown, the main idea of the present invention is to use the induced draft fan 3 to extract a part of the moisture from the moisture discharge chimney 1, after the proportion is controlled by the electric valve 2, through the induced draft fan 3, the rotary joint 4, the hollow cylinder reamer 5, It is screwed into the ball mill body 1 through the rotating steam injection port 6. During this process, the moisture in the wet steam can be used to fully contact the anhydrite A3 contained in the plaster, and the phase will change into anhydrite, thereby reducing the amount of plaster. Increase the content of anhydrous gypsum A3 and improve material properties.

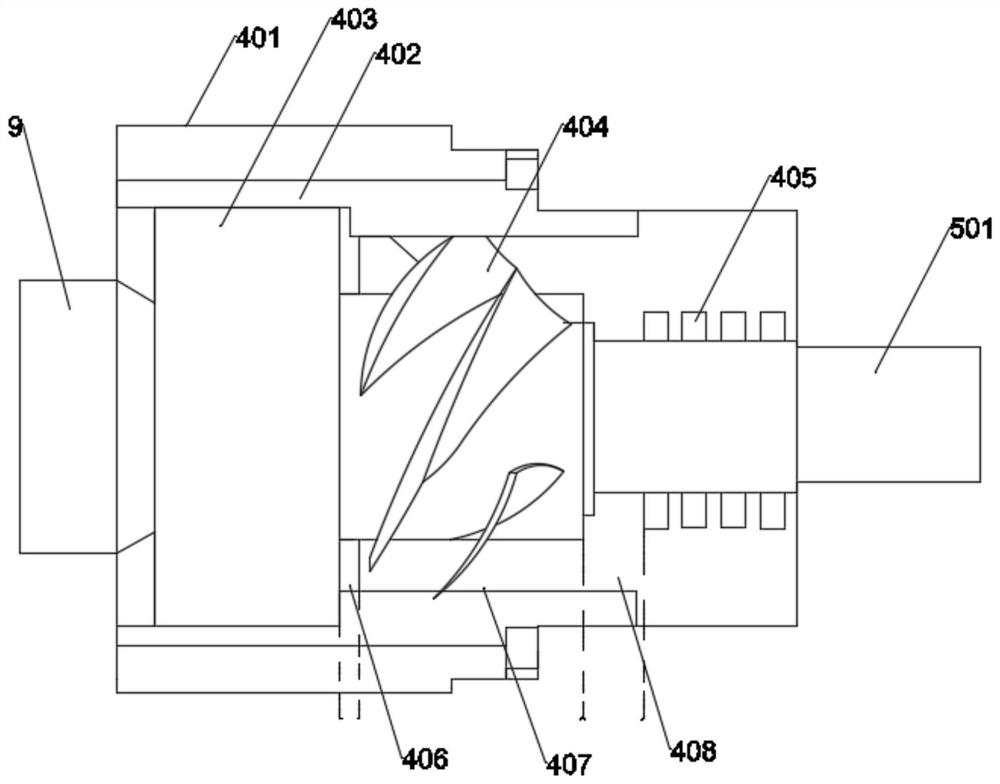

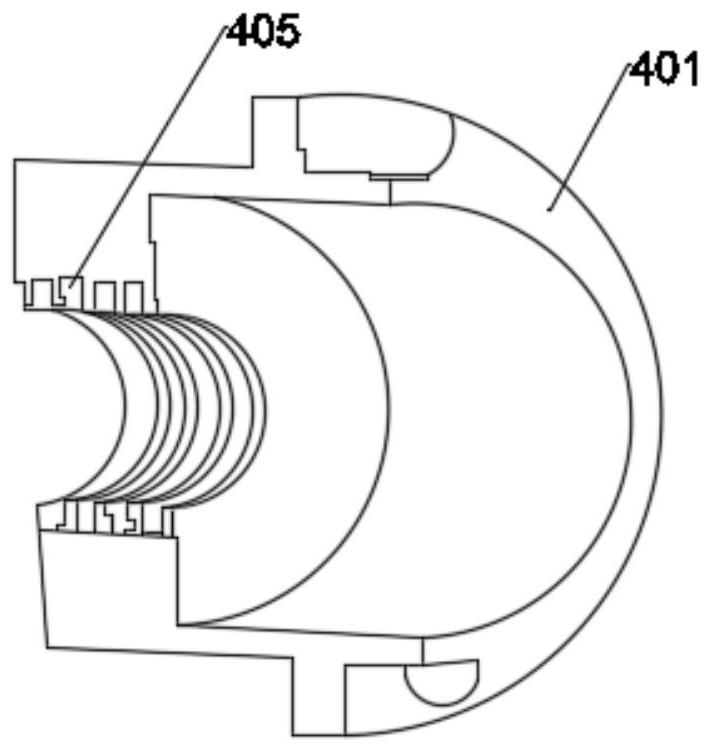

[0038] specific structure, such as figure 1 Shown: The device for improving the clinker phase composition during the ball milling process, including: a moisture discharge chimney 1, an induced draft fan 3, a hollow cylindrical reamer 5 and a ball mill body 10 connected in sequence, and the induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com