Method for producing gypsum plaster board by using calcium lignosulphonate/naphthalene-series composite water-reducing agents

A technology of plasterboard and composite water reducer, which is applied in the production of plasterboard, wood calcium and naphthalene composite water reducer, which can solve the problem of large water demand, waste of water resources and limited production capacity in gypsum board production and other issues, to achieve the effect of saving resources and energy, reducing water consumption, and reducing the ratio of water to paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

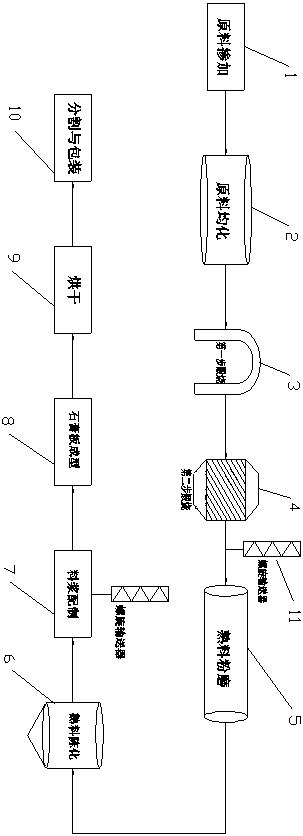

[0012] As shown in the figure, the desulfurized gypsum from different origins is mixed with raw materials according to a certain proportion 1, the mixed raw materials enter the silo and the raw materials are homogenized 2 and mixed. , control the water of crystallization at 10% to 11%, the clinker calcined in the first step is calcined at a low temperature and slow in the second part 4, the calcination time is 25min, the powder output temperature is controlled at 155°C, after the first step calcination and the second part After calcining, the cooked powder enters the ball mill for grinding 5, and before the cooked powder enters the ball mill, a quantitative wood calcium water reducer is added through the screw conveyor 11; the ground cooked powder enters the storage bin for aging 6, and the cooked powder After the powder is aged, water is added and ingredients are added for slurry preparation 7. At the same time, quantitative naphthalene-based water reducer is added through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com