A method for preparing solid waste-based cementitious materials by ultra-low carbon and ultra-low emission cascade grinding

An ultra-low-carbon, grinding technology, applied in cement production, etc., can solve the problems of low activity and strength of solid waste-based cementitious materials, and achieve enhanced strength, improved early compressive and flexural strength, and low standard viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

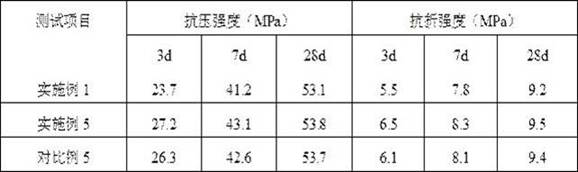

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing solid waste-based cementitious materials by ultra-low-carbon and ultra-low-emission cascade grinding, which includes the following steps:

[0027] S0, mixing 10 parts of triethanolamine with 3 parts of sodium tripolyphosphate, 7 parts of sodium fluoroaluminate, 3 parts of sodium diethyldithiocarbamate, 3 parts of polysuccinimide, and 30 parts of water to obtain a grinding aid ;

[0028] S1. Mix the slag and grinding aid at a mass ratio of 20:1, and then transport it to the vertical mill for grinding through the belt conveyor until the specific surface area is ≥ 600m 2 / kg, get the first slag, transport to 1# semi-finished product warehouse;

[0029] S2. Mix the slag and the grinding aid according to the mass ratio of 25:1, and then transport it to the vertical mill for grinding by the belt conveyor, and grind until the specific surface area is 500m 2 / kg-600m 2 / kg, to obtain the second slag, transported to 2# semi-fini...

Embodiment 2

[0033] This embodiment provides a method for preparing solid waste-based cementitious materials by ultra-low-carbon and ultra-low-emission cascade grinding, which includes the following steps:

[0034] S0, mixing 20 parts of triethanolamine with 5 parts of sodium tripolyphosphate, 10 parts of sodium fluoroaluminate, 5 parts of sodium diethyldithiocarbamate, 5 parts of polysuccinimide, and 50 parts of water to obtain a grinding aid ;

[0035] S1. Mix the slag and grinding aid at a mass ratio of 20:1, and then transport it to the vertical mill for grinding through the belt conveyor until the specific surface area is ≥ 600m 2 / kg, get the first slag, transport to 1# semi-finished product warehouse;

[0036] S2. Mix the slag and the grinding aid according to the mass ratio of 25:1, and then transport it to the vertical mill for grinding by the belt conveyor, and grind until the specific surface area is 500m 2 / kg-600m 2 / kg, to obtain the second slag, transported to 2# semi-fin...

Embodiment 3

[0040] This embodiment provides a method for preparing solid waste-based cementitious materials by ultra-low-carbon and ultra-low-emission cascade grinding, which includes the following steps:

[0041] S0, mixing 10 parts of triethanolamine with 3 parts of sodium tripolyphosphate, 7 parts of sodium fluoroaluminate, 3 parts of sodium diethyldithiocarbamate, 3 parts of polysuccinimide, and 30 parts of water to obtain a grinding aid ;

[0042] S1. Mix the slag and grinding aid at a mass ratio of 20:1, and then transport it to the vertical mill for grinding through the belt conveyor until the specific surface area is ≥ 600m 2 / kg, get the first slag, transport to 1# semi-finished product warehouse;

[0043] S2. Mix the slag and the grinding aid according to the mass ratio of 25:1, and then transport it to the vertical mill for grinding by the belt conveyor, and grind until the specific surface area is 500m 2 / kg-600m 2 / kg, to obtain the second slag, transported to 2# semi-fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com