Microcarrier system, bucket and cryopreservation method for biological material cryopreservation

A carrier system and biomaterial technology, applied in the field of micro-carrier systems, can solve the problems of large-scale sample cryopreservation and its development, low space utilization efficiency, and super-large space occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

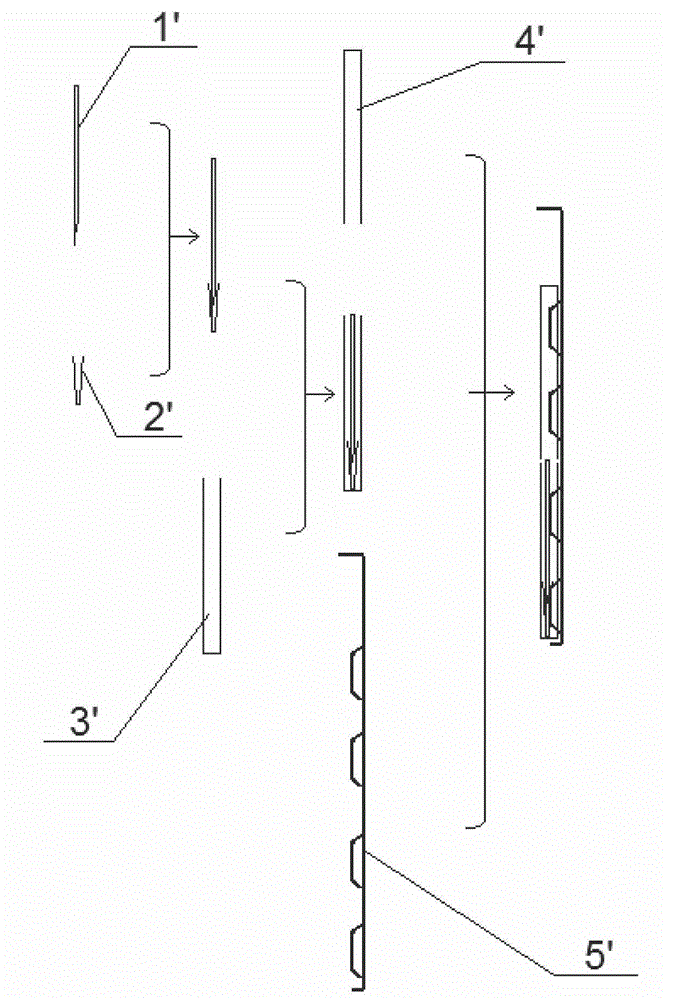

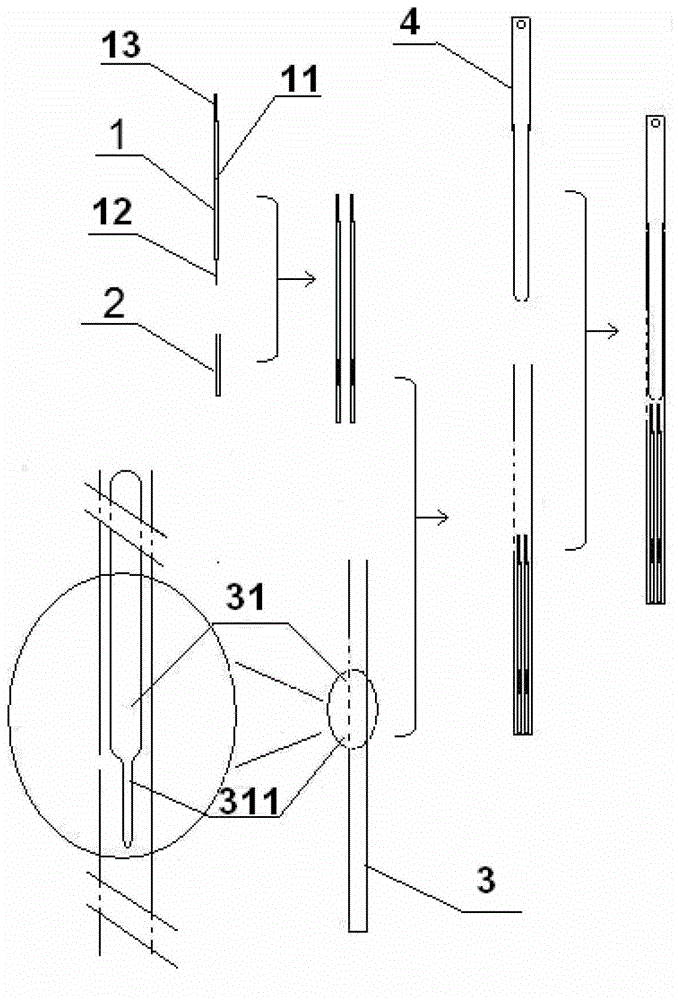

[0077]In this embodiment, the original one-end-opened rod-loading tube 3' is changed into a thinner and elongated rod-loading tube with an elongated window from the side, that is, notch 31 (rod loading opening), and at least a closed bottom end. 3. The loading and unloading of the loading rod in the loading rod tube is carried out from the side notch 31 through tweezers; the external force clamping type loading rod cap 4' is discarded, and the lower section is inserted into the loading rod from the top opening of the loading rod tube. The stop rod 4 fixed by friction in the rod barrel controls the opening length of the notch 31 by the length of the stop rod at the notch 31. When the opening is long, the loading rod 1 (loading unit) can be picked and placed. , when the opening is shorter, the sliding of the loading rod 1 in the loading rod tube 3 can be blocked. This eliminates the need for an external rod-carrying cap, thereby correspondingly abandoning the rod-carrying holder...

Embodiment 2

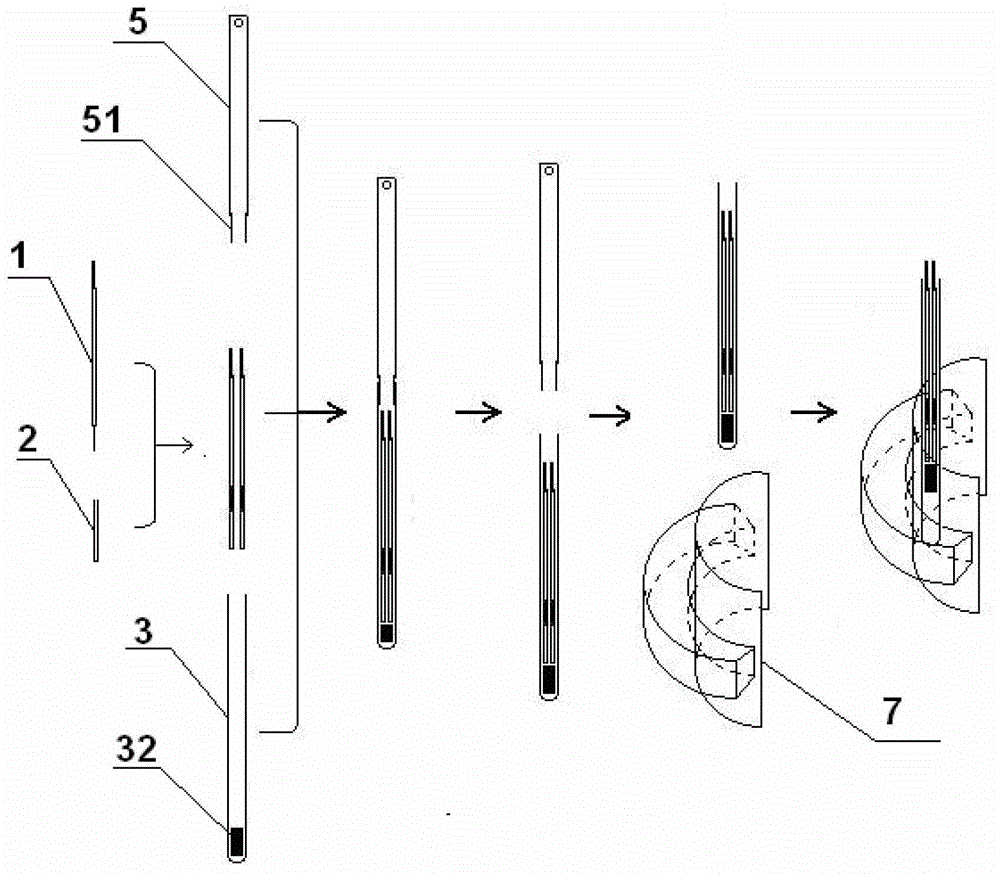

[0092] In this embodiment, the original one-end-opened rod-loading tube 3' is changed into a thinner and elongated one that opens from the top, that is, the opening of the rod-loading tube, and the bottom end is closed, and a movable iron block is placed at the bottom of the tube. Rod tube 3; the removal of the loading rod in the loading rod tube is: through the magnetic positioning concave seat, the movable iron block is driven up to raise the loading rod to expose the top loading rod tube opening; the external force clamping type loading rod cap is discarded The cover 4' is changed to a sleeve 5 with a lower connecting section that can be inserted into the rod-loading tube from the mouth of the rod-loading tube and fixed by friction, so as to close the rod-loading port and extend the cryopreservation unit to a length beyond the depth of the bucket of the liquid nitrogen tank . Thereby, the rod-loading tube holder for clamping the rod-loading tube cap that takes up the most s...

Embodiment 3

[0104] In the microcarrier system provided by the present invention, since the rod-loading tube is thinner, the amount of liquid nitrogen in the rod-loading tube is small during freezing storage, and the liquid nitrogen in the bucket is quickly leaked through the bottom mesh when the bucket is extracted. This makes a small amount of liquid nitrogen in the loading rod tube in a non-liquid nitrogen environment and is easy to completely volatilize. At this time, the frozen storage part of the biological material may not be in the protection of liquid nitrogen, which may easily cause abnormal thawing of the biological material and make the frozen storage fail.

[0105] refer to Figure 4 and 5 , the existing bucket 8' is closed with a side wall, and the bottom is provided with a mesh liquid hole 81'. This embodiment provides a side leakage bucket 8 suitable for storing miniature refrigeration units. The bottom of the bucket is In a closed shape, a liquid hole 81 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com