A kind of environment-friendly phase change gypsum board and preparation method thereof

A gypsum board and phase change technology, applied in the field of building materials, can solve the problems of high thermal conductivity, high energy storage density, easy precipitation corrosion, large supercooling degree, etc., and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

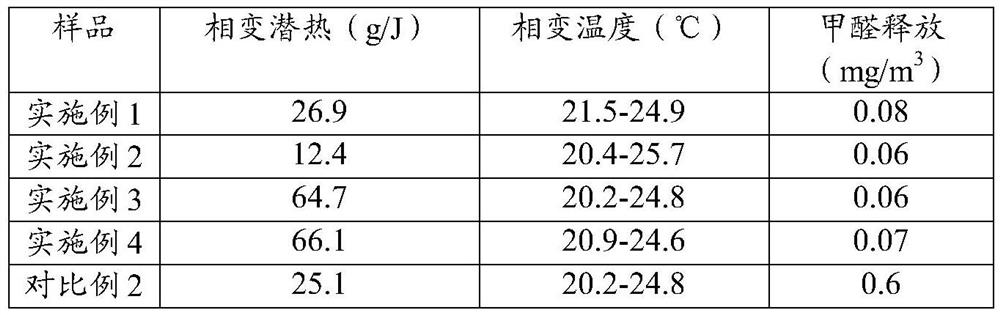

Examples

Embodiment 1

[0029] An environmentally friendly phase change paper gypsum plate (a phase change microcapsule material having a 15% by weight of dry base silica wall), the phase change paper plasterboard is prepared by the following method:

[0030]100 parts by weight of the desulfurization building cooked gypsum powder, 0.6 parts by weight of the modified starch, 0.01 parts by weight of the foaming agent, 3 parts by weight of the composite reinforcing agent, 0.05 parts by weight of the water reducer, 0.1 parts by weight, 30 parts by weight Microcapsule material emulsion and 55 parts by weight of water were added to the mixer and mixed, the slurry was made, and the surface paper was attached to the upper surface of the slurry, the lower surface was formed, and the phase change gypsum plate was obtained.

[0031] Among them, the composite enhancer consists of cement and silica ash, and their weight ratio is 100: 30.

[0032] The method of preparing the emulsion of the phase change microcapsule m...

Embodiment 2

[0035] An environmentally friendly phase change paper gypsum board (a phase change microcapsule material having a 5% by weight of dry base silica wall), the phase change paper plasterboard is prepared by the following method:

[0036] 100 parts by weight of the desulfurization building cooked gypsum powder, 0.4 parts by weight of the modified starch, 0.04 parts by weight of the foaming agent, 1 parts by weight of the composite reinforcing agent, 0.3 parts by weight of the water reducer, 0.3 parts by weight, 17.5 parts by weight Microcapsule material emulsion and 62.5 parts by weight of water were added to the mixer and mixed, the slurry was made, and the surface paper was attached to the upper surface of the slurry, the surface of the lower surface was formed, cut, and dried to obtain a phase change gypsum plate.

[0037] Among them, the composite enhancer is composed of lime and fly ash, and their weight ratio is 100: 50

[0038] The method of preparing the emulsion of the phase ...

Embodiment 3

[0041] An environmentally friendly phase change paper gypsum plate (a phase change microcapsule material having a 30% by weight of dry base silica wall), the phase change paper plasterboard is prepared by the following method:

[0042] 100 parts by weight of the desulfurization building, 0.01 parts by weight of a modified starch, 0.01 parts by weight of a composite reinforcing agent, 0.1 weight parts water reduction agent, 0.05 parts by weight of the concentrating agent, 80 parts by weight Microcapsule material emulsion and 28 parts by weight of water were added to the mixer and mixed, and the slurry was made, and the surface paper was attached to the upper surface of the slurry, the lower surface was formed, and the phase change gypsum plate was obtained.

[0043] Among them, the composite enhancer consists of cement and fly ash, and their weight ratio is 100: 20.

[0044] The method of preparing the emulsion of the phase change microcapsule material is to add water to the emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com