Ammonium bicarbonate compound stabilizer and preparation method thereof

A compound stabilizer and ammonium bicarbonate technology, which is applied in the direction of ammonium orthophosphate fertilizer, ammonium salt fertilizer, fertilizer mixture, etc., to achieve the effect of improving stability, improving physical and chemical characteristics, and increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

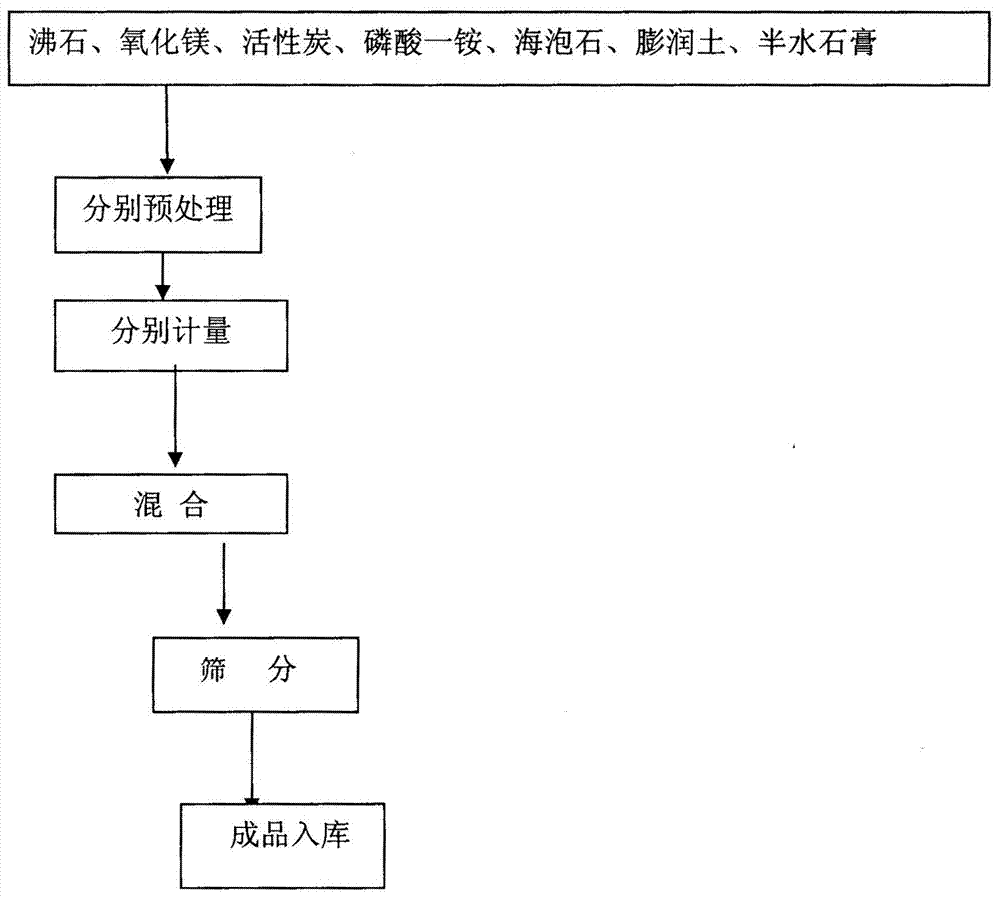

[0021] The weight ratios of zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum described in this embodiment are 22:16; 20:8:12; 5:10.

[0022] Concrete preparation method comprises the following steps:

[0023] a. The zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum are respectively crushed and pretreated; the crushed pretreated zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, The particle size of hemihydrate gypsum is 80 mesh;

[0024] b. Weigh and mix the crushed pretreated zeolite, magnesia, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum according to the proportion to obtain the mixed powder, and mix the mixed powder with 25kg / The bag is sealed and packaged to obtain the finished product.

Embodiment 2

[0026] The weight ratios of zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum described in this embodiment are 28:18:24:10:14; 6:12.

[0027] Concrete preparation method comprises the following steps:

[0028] a. The zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum are respectively crushed and pretreated; the crushed pretreated zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, The particle size of hemihydrate gypsum is 90 mesh;

[0029] b. Weigh and mix the crushed pretreated zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum according to the proportion to obtain a mixed powder, and mix the mixed powder with 40kg / The bag is sealed and packaged to obtain the finished product.

Embodiment 3

[0031] The weight ratio of zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite and hemihydrate gypsum described in this embodiment is 22:20:28:20:16:8:16.

[0032] Concrete preparation method comprises the following steps:

[0033] a. The zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum are respectively crushed and pretreated; the crushed pretreated zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite, The particle size of hemihydrate gypsum is 100 mesh;

[0034] b. Weigh and mix the crushed pretreated zeolite, magnesia, activated carbon, monoammonium phosphate, sepiolite, bentonite, and hemihydrate gypsum according to the proportion to obtain the mixed powder, and mix the mixed powder with 50kg / The bag is sealed and packaged to obtain the finished product.

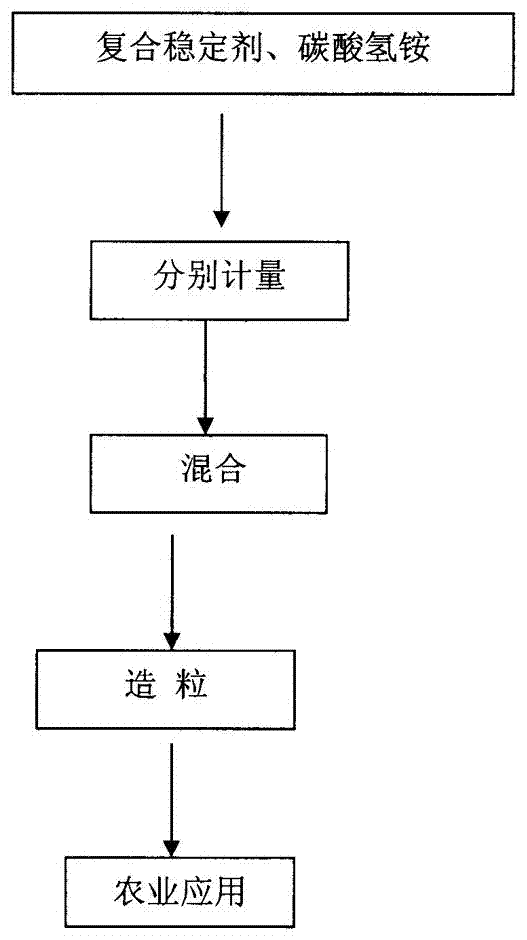

[0035] The ammonium bicarbonate composite stabilizer prepared in the above exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com