Method for drying and pelleting desulfurization gypsum for cement retarder

The technology of desulfurization gypsum and setting control agent is applied in the field of desulfurization gypsum drying of granulation and cement setting control agent, which can solve the problems of high water content and high cost, and achieve the effects of low free water content, easy control and stable cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

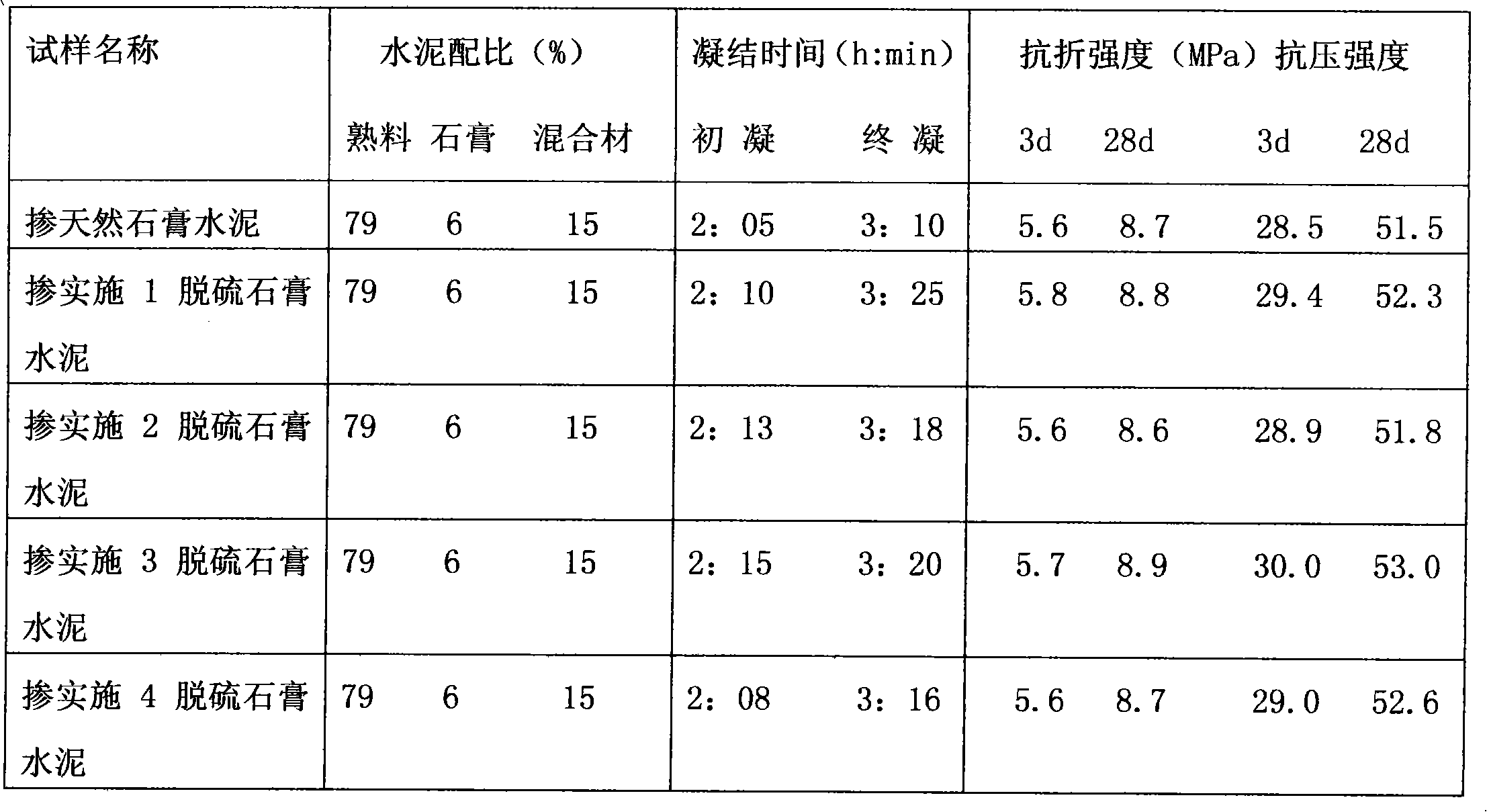

Examples

Embodiment 1

[0013] Use 910g of desulfurized gypsum with a water content of 13.6%, add 30g of quicklime, 40g of aluminate cement, and 20g of Portland cement; then stir in a mixer at 30°C for 5 minutes, and store at 40°C-30°C for 1 day to obtain dryness. Granular product; product particle size: 0.2mm sieve 65%, free water content 0.84%, SO 3 Content 40.69%.

Embodiment 2

[0015] Use 900g of desulfurized gypsum with a water content of 12.8%, add 20g of slaked lime, 20g of calcium carbide slag, 30g of sulphoaluminate cement, and 30g of iron-aluminate cement; then stir in a mixer at 25°C for 5 minutes, and store at 50°C-35°C A dry, granular product can be obtained in 1 day; product particle size: 55% of 0.2mm sieve, free water content of 1.60%, SO 3 Content 40.10%.

Embodiment 3

[0017] Use 860g of desulfurized gypsum with a water content of 13.6%, mix with 60g of quicklime, 30g of sulphoaluminate cement, and 50g of Portland cement; then stir in a mixer at 40°C for 5 minutes, store at 50°C-40°C for 1 day to dry , granular products; product particle size: 0.2mm sieve 70%, free water content 1.04%, SO 3 Content 39.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com