Method for strengthening anaerobic digestion based on sludge solid-liquid interface updating

An anaerobic digestion and liquid interface technology, applied in the field of sludge recycling, can solve the problem of low efficiency of sludge anaerobic digestion, and achieve the effect of improving electron utilization efficiency, changing water distribution, and increasing surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

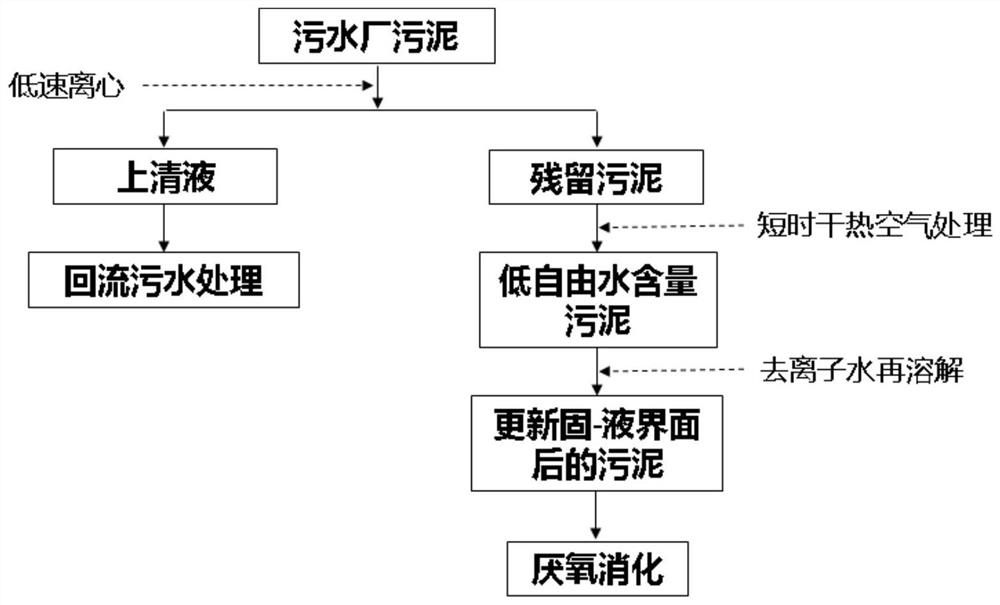

Image

Examples

Embodiment 1

[0032] 1. Take 1000mL of sewage plant sludge and centrifuge for 20min at a centrifugal force of 2000g for solid-liquid separation, and collect residual sludge;

[0033] 2. Put the residual sludge in 1 into an oven at 80°C, and use dry hot air to treat it at a constant temperature for 120 minutes;

[0034] 3. Use 500mL of demineralized water to redissolve the sludge treated with dry hot air at constant temperature in 2, and stir at 200r / min for 2h;

[0035] 4. Move the sludge in 3 into the anaerobic reactor as a whole, and use hydrochloric acid or lye to adjust the pH to 6.0-8.0, and carry out anaerobic digestion at 37°C for 15 days at an inoculation ratio of 1:2 (VS). methane. The biochemical methane potential tester (BMP, AMPTSⅡ) was used to automatically record data and calculate the methane production per unit of organic matter (mL CH 4 / g VS) The results show that the sludge treated by this method has a unit organic matter methane yield (mL CH 4 / g VS) increased by 80%....

Embodiment 2

[0037] 1. Take 1000mL of sewage plant sludge and centrifuge at 4000g for 10 minutes to separate solid and liquid, and collect residual sludge;

[0038] 2. Put the residual sludge in 1 into an oven at 105°C, and use dry hot air to treat it at a constant temperature for 90 minutes;

[0039] 3. Use 500mL of demineralized water to redissolve the sludge that has been treated with dry hot air at a constant temperature in 2, and stir at a speed of 300r / min for 2h;

[0040] 4. Move the sludge in 3 into the anaerobic reactor as a whole, and use hydrochloric acid or lye to adjust the pH to 6.0-8.0, and carry out anaerobic digestion at 37°C for 15 days at an inoculum ratio of 1:1 (VS). methane. The biochemical methane potential tester (BMP, AMPTSⅡ) was used to automatically record data and calculate the methane production per unit of organic matter (mL CH 4 / g VS).

[0041] The results show that the sludge treated by this method has a unit organic matter methane yield (mL CH 4 / g VS)...

Embodiment 3

[0043] 1. Take 1000mL of sewage plant sludge and centrifuge at 6000g for 10 minutes to separate solid and liquid, and collect residual sludge;

[0044] 2. Put the residual sludge in 1 into a 95°C oven, and use dry hot air to treat it at a constant temperature for 90 minutes;

[0045] 3. Use 500mL of demineralized water to redissolve the sludge that has been treated with dry hot air at a constant temperature in 2, and stir at a speed of 400r / min for 0.5h;

[0046] 4. Move the sludge in 3 into the anaerobic reactor as a whole, and use hydrochloric acid or lye to adjust the pH to 6.0-8.0, and carry out anaerobic digestion at 37°C for 15 days at an inoculation ratio of 1:2 (VS). methane. The biochemical methane potential tester (BMP, AMPTSⅡ) was used to automatically record data and calculate the methane production per unit of organic matter (mL CH 4 / g VS).

[0047] The results show that the sludge treated by this method has a unit organic matter methane yield (mL CH 4 / g VS)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com