Food-grade carbon dioxide high-efficiency purifying system and process thereof

A carbon dioxide and food-grade technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as difficulties, high operating costs, and substandard industrial-grade indicators, and achieve reduced types of impurities, high desulfurization efficiency, and low cost. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

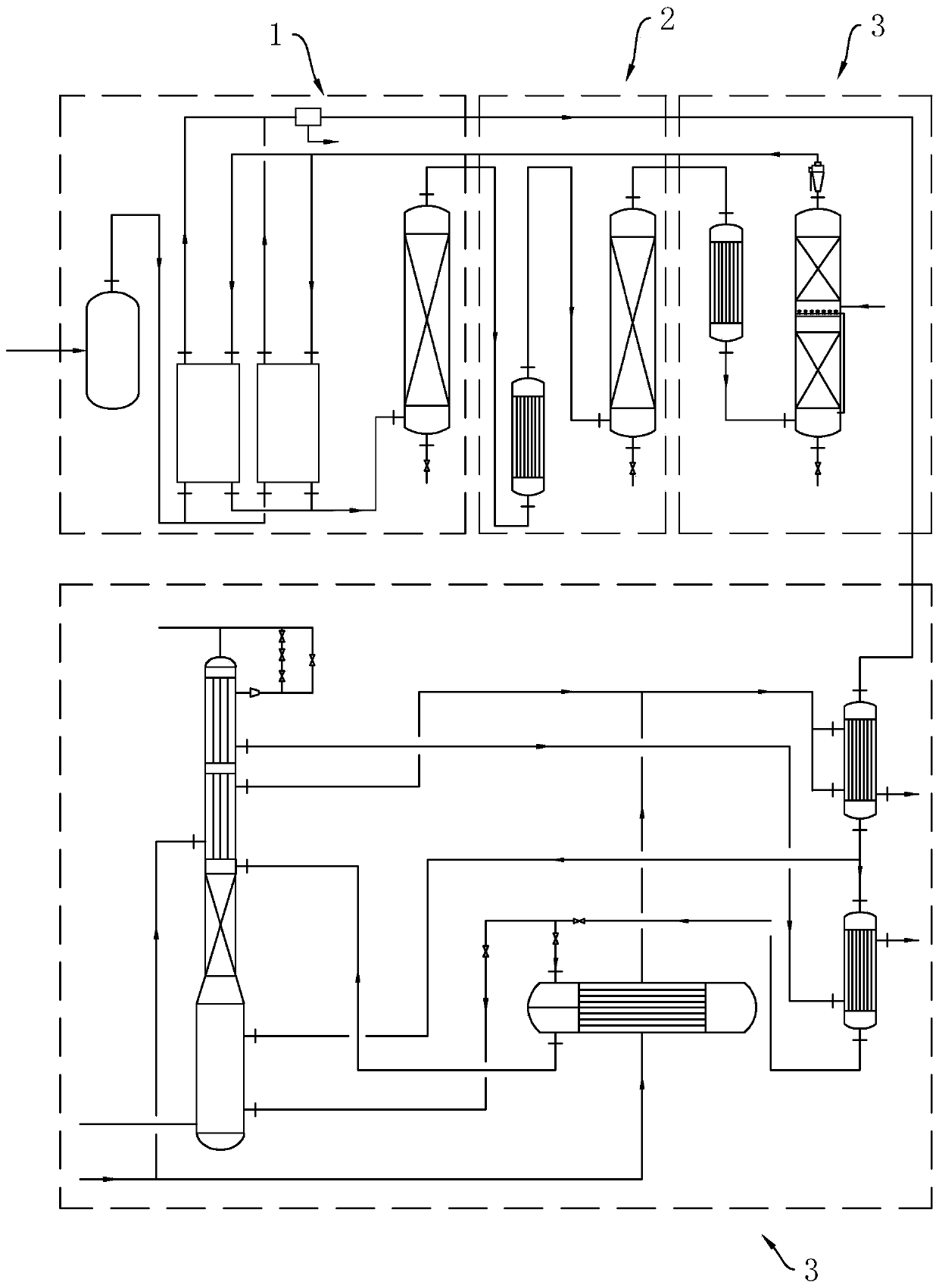

[0054] as attached figure 1 As shown, a food-grade carbon dioxide high-efficiency purification system includes a compression power unit 1, a hydrolysis desulfurization unit 2, a fine desulfurization unit 3, and a purification unit 4 along the reaction process.

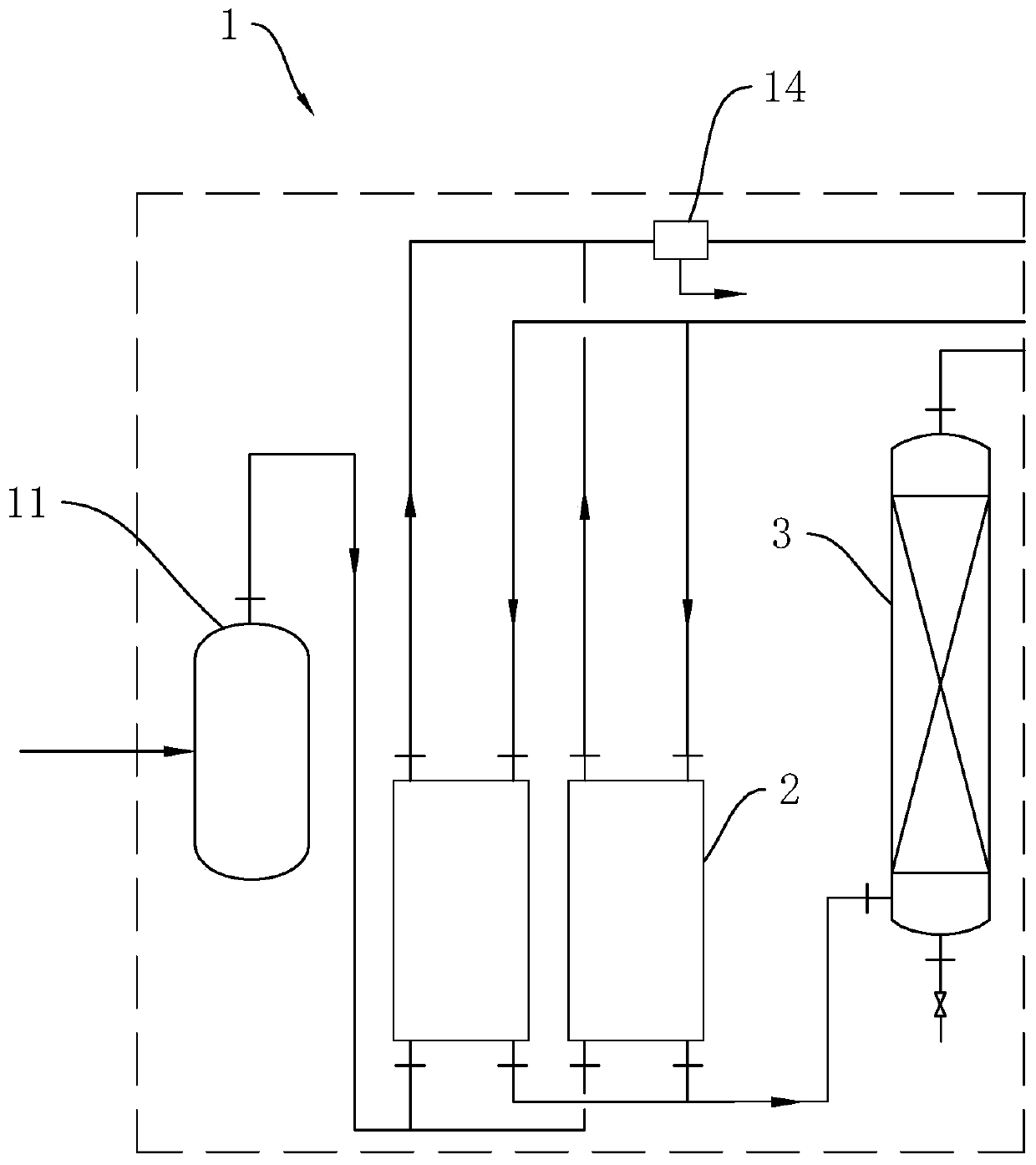

[0055] as attached figure 2 As shown, the compression power unit 1 includes a buffer tank 11 , a compressor 12 and a filter tank 13 . Wherein the buffer tank 11 communicates with the raw material gas of carbon dioxide to ease the pressure fluctuation of the raw material gas.

[0056] Compressor 12 is the prior art CO 2 The compressor 12 is a prior art and will not be further elaborated. The number of compressors 12 can be determined according to actual conditions. Here, the number of compressors 12 is two, and the two compressors 12 are connected in parallel, and both compressors 12 are connected in series downstream of the buffer tank 11 .

[0057] The filter tank 13 is connected in series with the downstream of ...

Embodiment 2

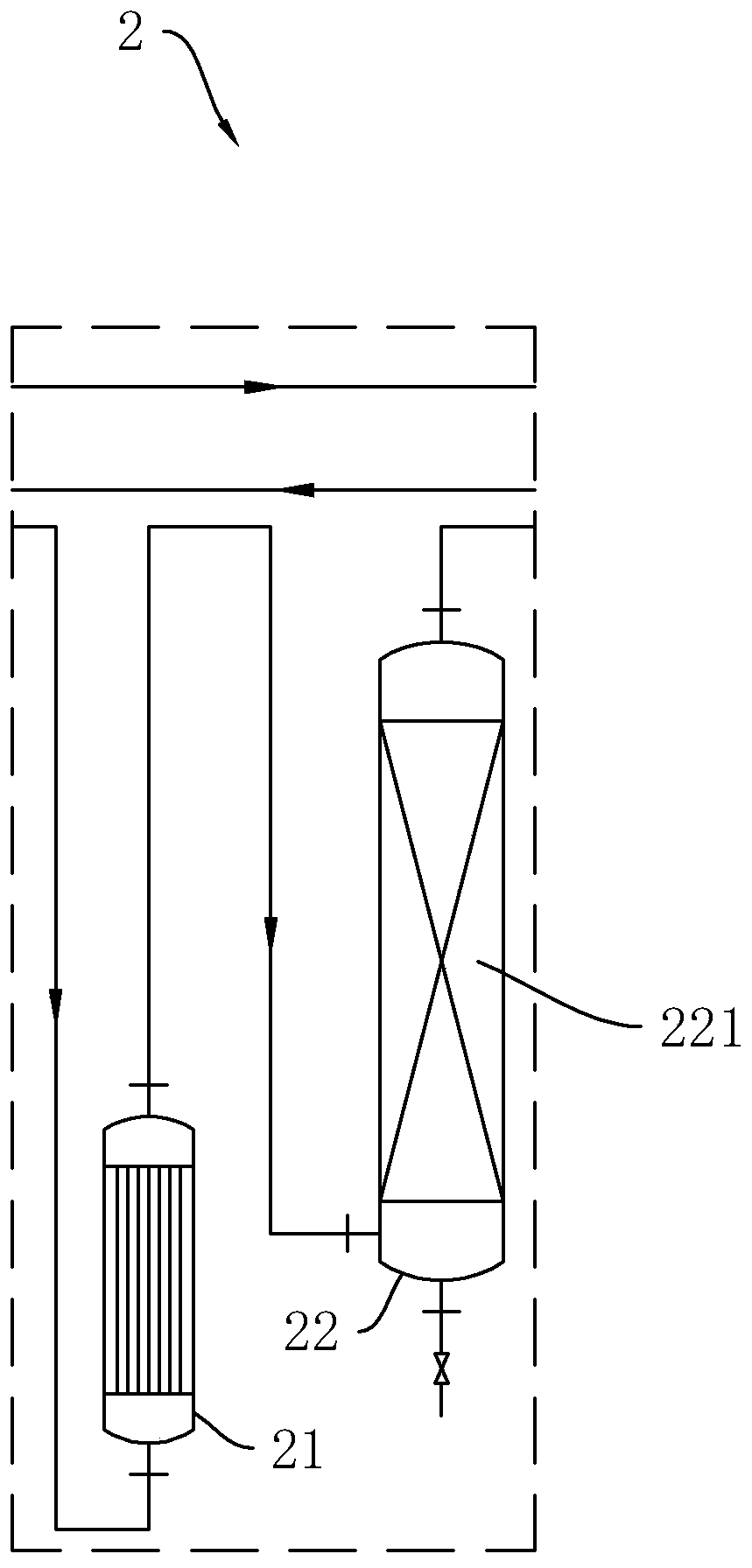

[0078] A high-efficiency purification process of food-grade carbon dioxide. The raw material gas enters the system from the compression power unit 1, and is pressurized and transported to the hydrolysis desulfurization unit 2 in the compression power unit 1. In the hydrolysis desulfurization unit 2, COS is hydrolyzed and decomposed to obtain hydrolysis desulfurization gas, and then in the fine desulfurization In unit 3, sulfur-containing components are oxidized and removed to obtain refined desulfurized gas with a sulfur content of less than 10 ppm, and then in purification unit 4 to remove moisture and rectify and purify to obtain food-grade carbon dioxide.

[0079] Specifically, there are the following sequential process steps,

[0080] T1: The raw gas containing carbon dioxide enters the compression power unit 1, buffered by the buffer tank 11, compressed and boosted by the compressor 12, filtered by the filter tube, and then sent to the hydrolysis desulfurization unit 2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com