High-strength wear-resistant concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of concrete, can solve the problems of concrete wear and deterioration, affecting the service life of concrete, etc., and achieve the effects of improving bonding effect, improving bonding effect and structural density, and improving mechanical strength and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

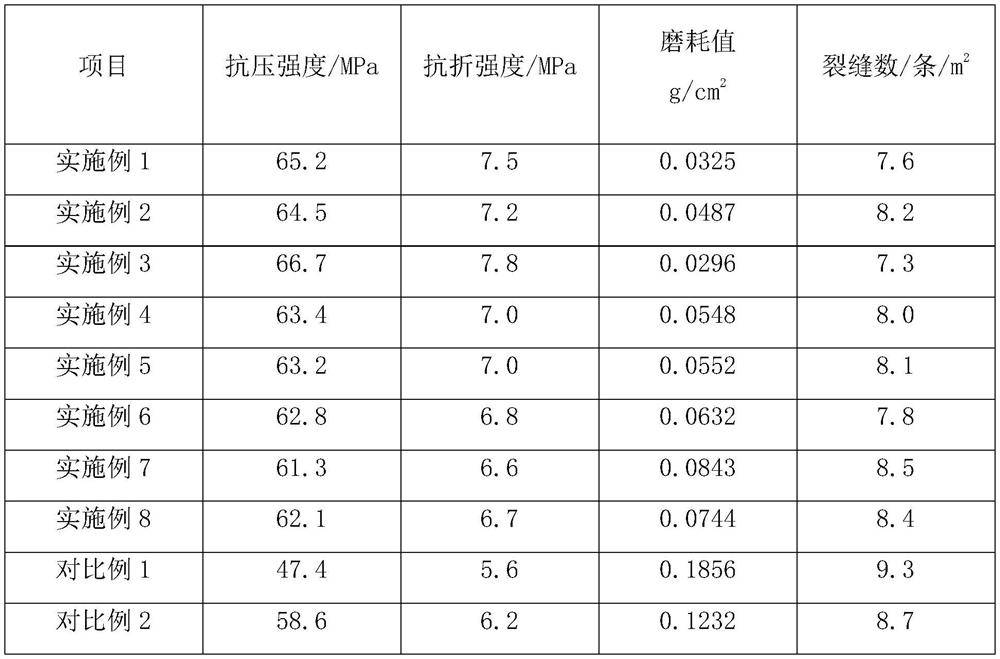

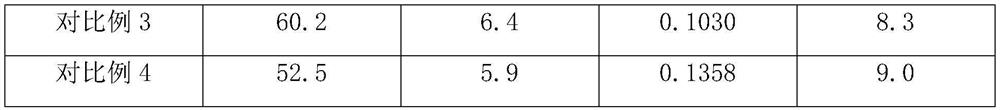

Examples

preparation example Construction

[0039] Preparation Example of Coated Aluminum Nitride

[0040] The following raw materials are all commercially available.

preparation example 1

[0041] Preparation example 1: coated aluminum nitride is prepared by the following method:

[0042] Weigh beeswax and heat to melt to obtain beeswax liquid; Weigh 1kg beeswax liquid and spray it into 3.8kg aluminum nitride, the particle size of aluminum nitride is 100 mesh, the spraying speed of beeswax liquid is 3g / s, during the spraying process of beeswax liquid Aluminum nitride is continuously stirred at a speed of 500r / min, then dried and ground to obtain coated aluminum nitride, and the coated aluminum nitride is passed through a 50-mesh sieve.

preparation example 2

[0043] Preparation example 2: coated aluminum nitride is prepared by the following method:

[0044]Weigh beeswax and heat it to melt to obtain beeswax liquid; take 1kg beeswax liquid and spray it into 2kg aluminum nitride, the particle size of aluminum nitride is 80 mesh, the spraying speed of beeswax liquid is 1g / s, nitrogen in the process of beeswax liquid spraying The aluminum oxide is continuously stirred at a speed of 300r / min, then dried and ground to obtain coated aluminum nitride, and the coated aluminum nitride is passed through a 20-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com