Method of eliminating magnesium sulfate from magnesium sulfate containing waste water solution

A magnesium sulfate and wastewater technology, which is applied in chemical instruments and methods, water pollutants, frozen water/sewage treatment, etc., can solve the problems of magnesium sulfate waste, secondary environmental pollution, etc., and achieves low operating cost, low impurity content, Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

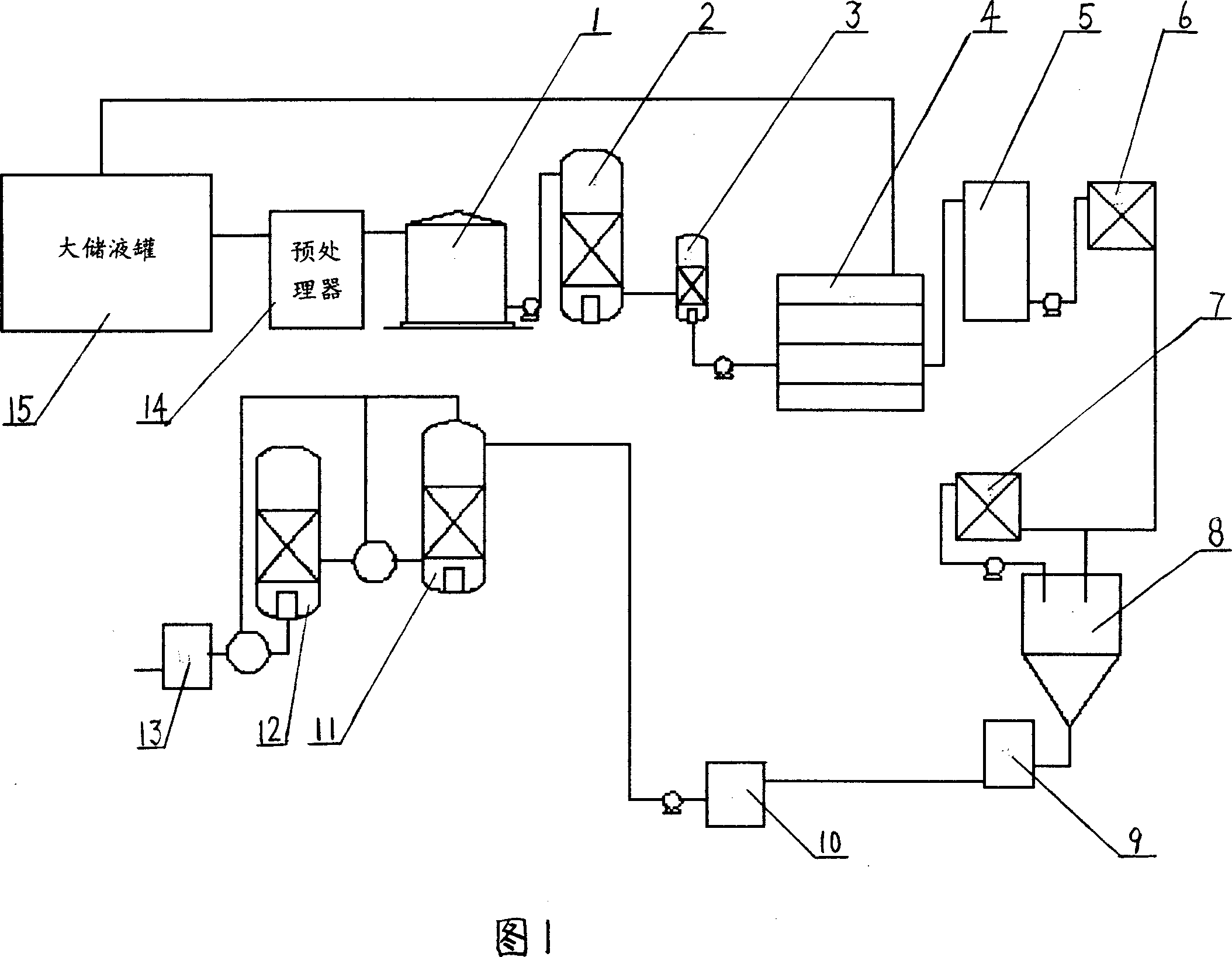

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below.

[0020] The microfiltration membrane materials used in the microfiltration membrane device are polypropylene (PP), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), carbon microporous tubes, metal microporous tubes and ceramics One of the microporous tubes.

[0021] The nanofiltration membrane material adopted in the nanofiltration membrane device is polysulfone (PS), composite film (TFM), cellulose acetate (CA), aromatic polyamide (PA), polyvinyl alcohol (PVA), sulfone One of polyethersulfone (SPES).

[0022] During nanofiltration, the temperature of the magnesium sulfate-containing wastewater solution is controlled between 40 and 50°C.

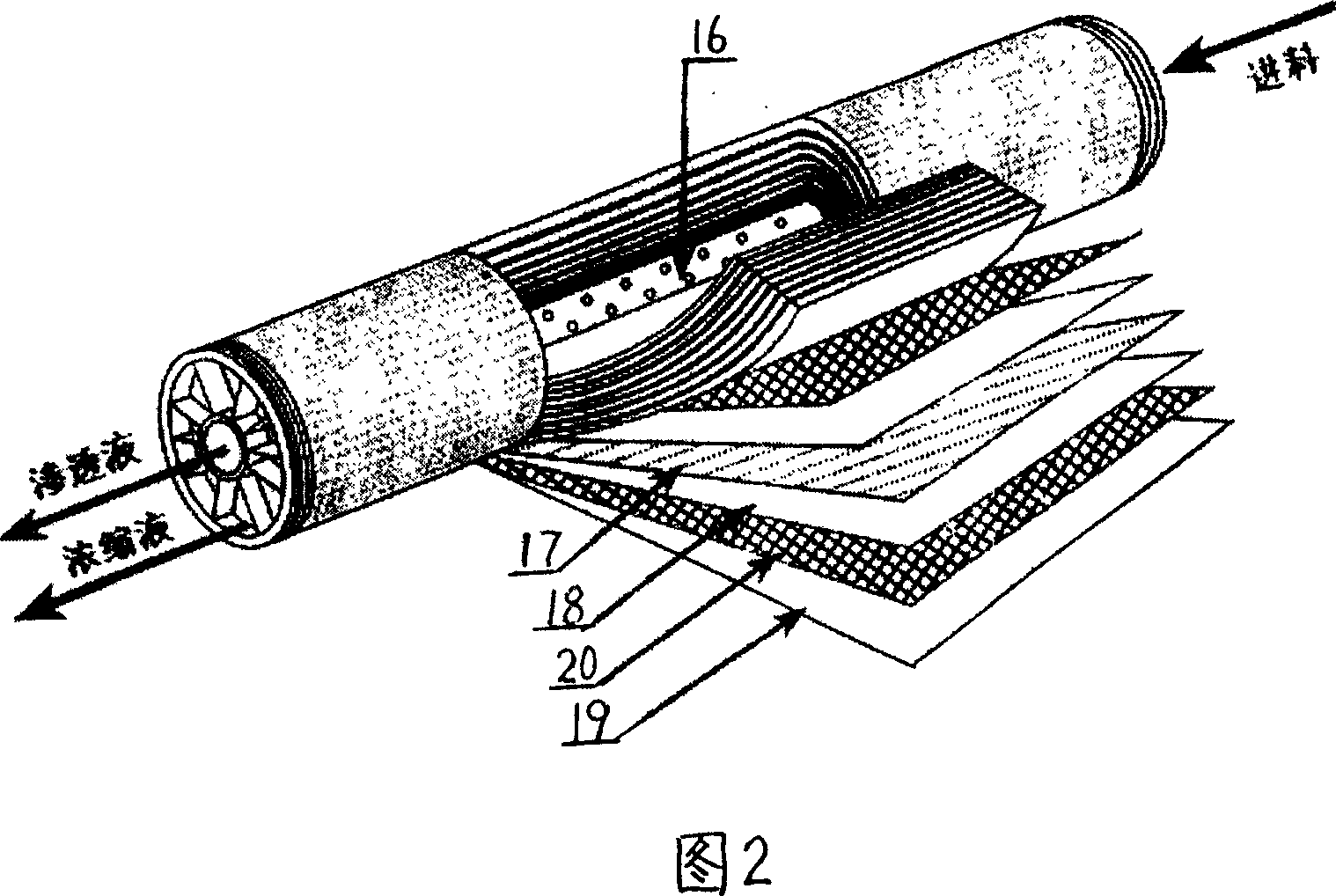

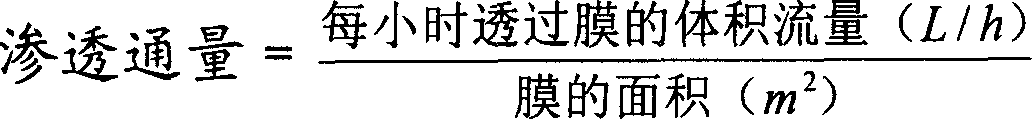

[0023] The nanofiltration membrane device in the present invention adopts membrane separation technology. Whether a membrane can separate a dissolved component from solution depends on the size, charge, shape of that component and its interaction with the membrane sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com