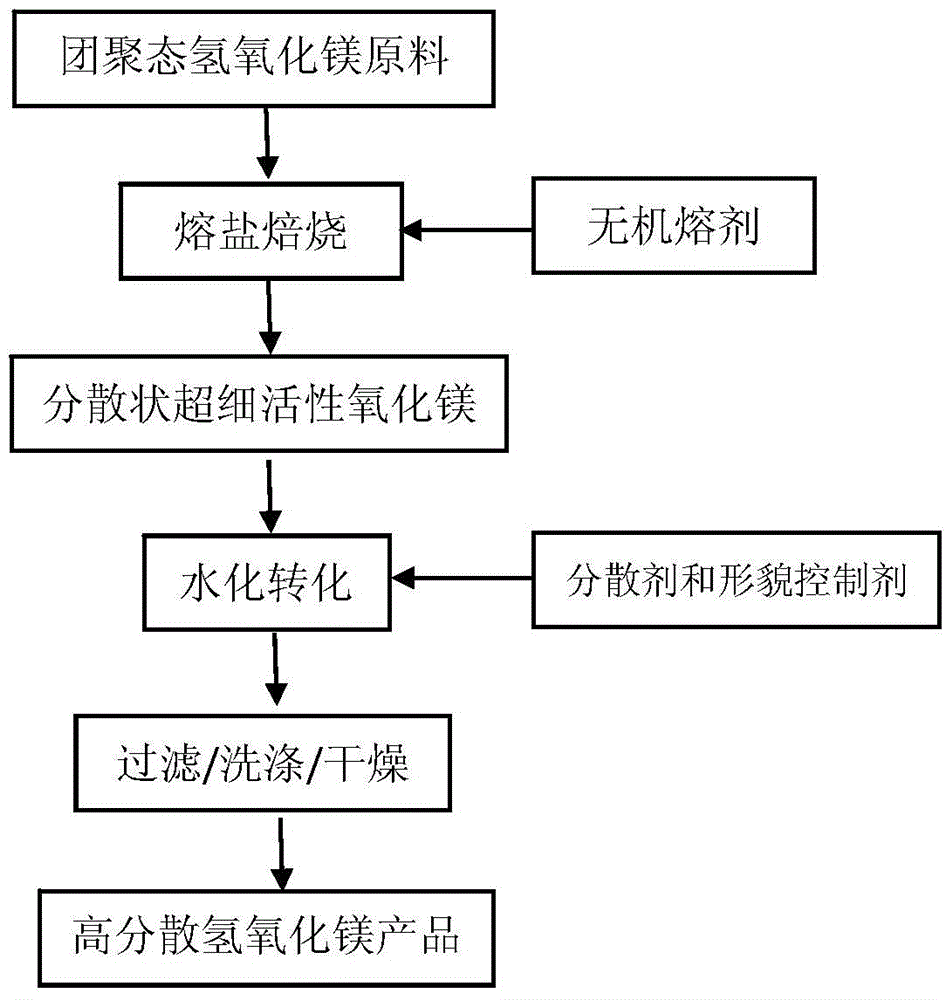

A method for preparing highly dispersed magnesium hydroxide using agglomerated magnesium hydroxide as raw material

A high-dispersion technology of magnesium hydroxide, applied in the direction of magnesium hydroxide, etc., can solve the problems of restricting industrial application and harsh conditions, and achieve the effect of high added value, regular shape and good dispersion of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

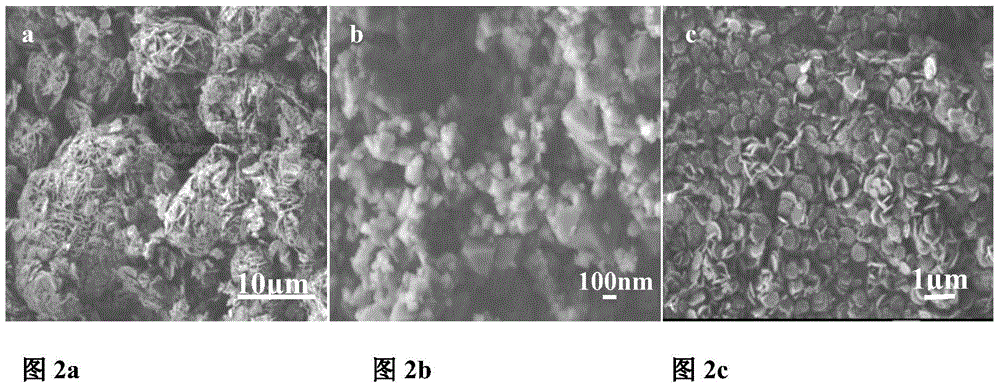

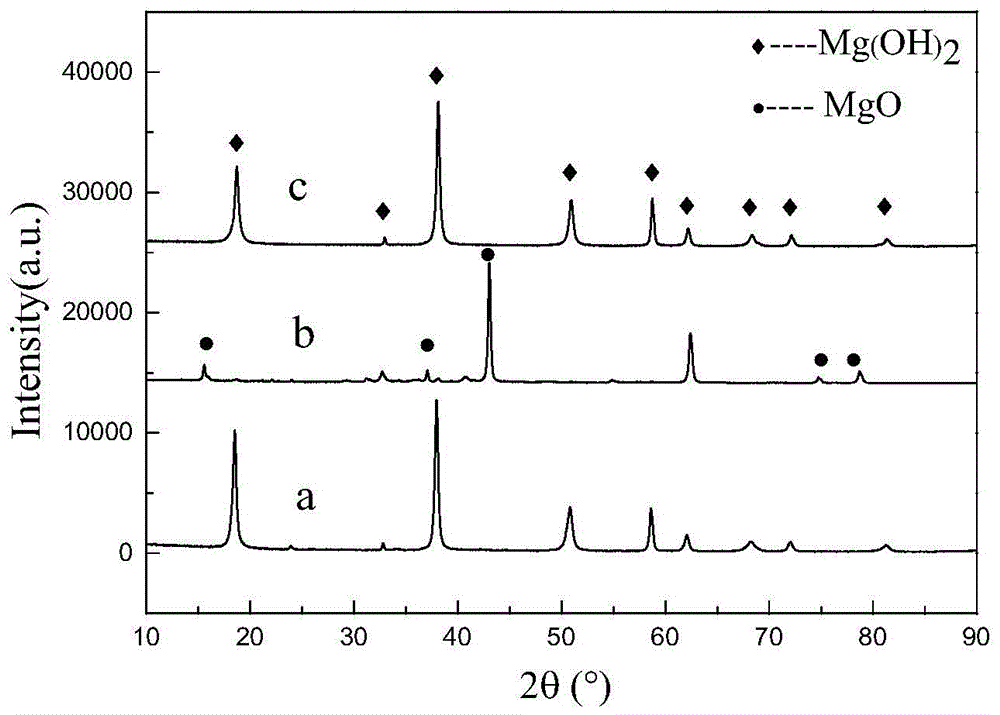

Embodiment 1

[0024] Weigh 100 grams of agglomerated magnesium hydroxide raw material (main content 95wt%, average primary particle size 0.1 micron, average agglomerated particle size 50 microns) and 1 gram of sodium oxalate, mix and place in an alumina crucible, heat up (1°C / min ) to 300°C for 6 hours at a constant temperature to obtain dispersed ultrafine activated magnesia; add dispersed ultrafine activated magnesia to an aqueous solution containing 0.01wt% sodium lauryl sulfate to make a solid content rate of 0.5wt% Suspension, hydration conversion at 10°C and stirring (50 rpm) for 0.5 hours, filtered, washed, and dried (80°C, hour), to obtain an average primary particle size of 0.1 microns, an average aggregated particle size of 0.5 microns, and a main content of Up to 95wt% highly dispersed magnesium hydroxide product.

Embodiment 2

[0026]Take by weighing 100 grams of agglomerated magnesium hydroxide raw material (main content 99.5wt%, average primary particle size 3 microns, average agglomerated particle size 50 microns) and 30 grams of magnesium oxalate, mix and place alumina crucible, heat up (50 ℃ / Point) to 700 DEG C, constant temperature reaction 0.5 hour, obtain dispersed superfine activated magnesia; Add dispersed superfine activated magnesia to the aqueous solution containing 20wt% sodium dodecylbenzenesulfonate and 20wt% sodium hydroxide, prepare Become a suspension with a solid content rate of 40wt%, hydration conversion at 100°C and stirring (800 rpm) for 6 hours, filter, wash, and dry (110°C, 6 hours) to obtain an average primary particle size of 2 microns, the average A highly dispersed magnesium hydroxide product with an aggregate particle size of 4 microns and a main content of 99.8 wt%.

Embodiment 3

[0028] Weigh 100 grams of agglomerated magnesium hydroxide raw material (main content 98.5wt%, average primary particle diameter 1.5 microns, average aggregated particle diameter 25 microns), 15 grams of ammonium oxalate and 1 gram of sodium chloride, mix and place in an alumina crucible , heating up (15 DEG C / min) to 550 DEG C and then reacting at a constant temperature for 5 hours to obtain dispersed ultrafine activated magnesium oxide; The aqueous solution is made into a suspension with a solid content rate of 10wt%, hydrated at 40°C and stirred (450 rpm) for 1 hour, filtered, washed, and dried (105°C, 2 hours) to obtain the average primary particle size Highly dispersed magnesium hydroxide product with 1.8 microns, average agglomerated particle size of 3 microns, and main content of 97.7 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com