Preparation method of basic magnesium sulfate whiskers

A magnesium sulfate whisker, basic technology, applied in directions such as magnesium sulfate, can solve problems such as waste, high production cost, complex process, etc., and achieve the effects of reducing pollution and waste, reducing preparation cost, and simplifying preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

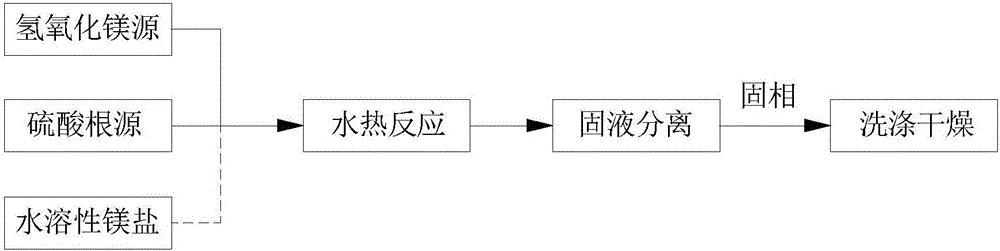

[0029] Reference figure 1 The method for preparing basic magnesium sulfate whiskers according to the present invention includes the following steps:

[0030] S1. Mixing a source of magnesium hydroxide, a source of sulfate and water to obtain a mixture.

[0031] The source of magnesium hydroxide refers to crude magnesium hydroxide in which the mass percentage of magnesium hydroxide is not less than 50%, preferably not less than 60%; the source of magnesium hydroxide can be salt lake brine, oil field water or magnesium ore treatment process By-product magnesium hydroxide slag; of course, in order to further increase the content of magnesium hydroxide in the magnesium hydroxide source, the magnesium hydroxide source can be washed with water to obtain purified magnesium hydroxide with a magnesium hydroxide content close to 100%.

[0032] Preferably, the mixture also includes a water-soluble magnesium salt; that is, it is preferable to mix a magnesium hydroxide source, a sulfate source, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com