Method for preparing vanadium pentoxide

A vanadium pentoxide, preparation process technology, applied in the field of preparation of vanadium pentoxide, can solve the problems of reducing the economic value of vanadium products, affecting the purity of vanadium pentoxide, etc., to achieve simple process, good impurity control, and increase economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

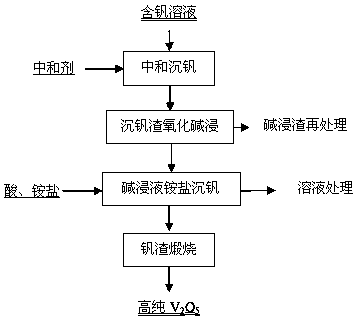

[0024] A method for preparing vanadium pentoxide. The preparation process is to use raw materials such as stone coal and vanadium slag, and use methods such as sulfuric acid direct leaching, sulfuric acid pressure leaching, roasting-acid leaching, etc. to obtain vanadium-containing 0.5-50g / L acidic The solution is the raw material, and the solution can contain Fe 2+ , Fe 3+ 、Al 3+ , Zn 2+ , Mg 2+ , Ca 2+ and other impurity ions, the vanadium in the solution must be three or four valent, if there is pentavalent vanadium, add reducing agent such as iron powder or sodium sulfite to reduce, control the solution potential 100 ~ 350mV, so that the pentavalent vanadium in the solution is basically reduced to 4 Valence, to ensure the precipitation rate of vanadium. Its steps include:

[0025] (1) Shen vanadium

[0026] The vanadium-containing solution was treated with CaCO 3 , CaO, MgO, MgCO 3 , NaOH, Na 2 CO 3 Adjust the pH to 4.0-4.5 with alkaline substances, react at 20°...

Embodiment 1

[0034] (1) A vanadium-containing solution obtained by direct sulfuric acid leaching of a stone coal vanadium ore, its composition is V1.69g / L, Fe 5.32g / L, Al 8.56g / L, Mg 2.82g / L, Zn 1.58g / L , Ca 0.70g / L, K 2.35g / L. The potential of the solution is 310mV, add CaCO3 at room temperature to adjust the pH to 4.3, age for 2 hours, filter to obtain the filter residue and filtrate, the vanadium concentration in the filtrate is 0.025g / L, and the vanadium content in the filter residue is 4.54%;

[0035] (2) Take the filter residue obtained by precipitation of vanadium for oxidative alkali leaching. The ratio of alkali leaching liquid to solid is 4:1. The oxidant is sodium chlorate. Add 1.04 times the theoretical amount. 3h, filter to obtain the alkaline immersion solution containing vanadium 11.58g / L;

[0036] (3) Neutralize the alkaline immersion solution with sulfuric acid to pH = 2.0, add 2 times the theoretical amount of ammonium sulfate at the same time, raise the temperature to 8...

Embodiment 2

[0039] (1) A vanadium-containing solution obtained from a stone coal vanadium ore through sulfuric acid pressure oxidation leaching, its composition is V1.89g / L, Fe 4.25g / L, Al 4.55g / L, Mg 4.60g / L, Zn 0.80g / L, Ca 0.70g / L, K 2.35g / L, the potential of the solution is 420mV, add iron powder to control the potential of the solution to 120mV, then add MgO to adjust the pH to 4.5, age at room temperature for 2h, filter to obtain the filter residue and filtrate , the vanadium content in the filtrate is 0.05g / L, and the vanadium content in the filter residue is 11.32%;

[0040](2) Take the filter residue obtained by precipitation of vanadium and carry out oxidative alkali leaching. The ratio of liquid to solid in alkali leaching is 10:1. Add hydrogen peroxide which is twice the theoretical amount. The alkali leaching controls the pH=7.0-8.0 and the oxidation potential is 950mV to obtain 10.03g / mV of vanadium. L of alkaline immersion solution;

[0041] (3) Neutralize the alkaline imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com