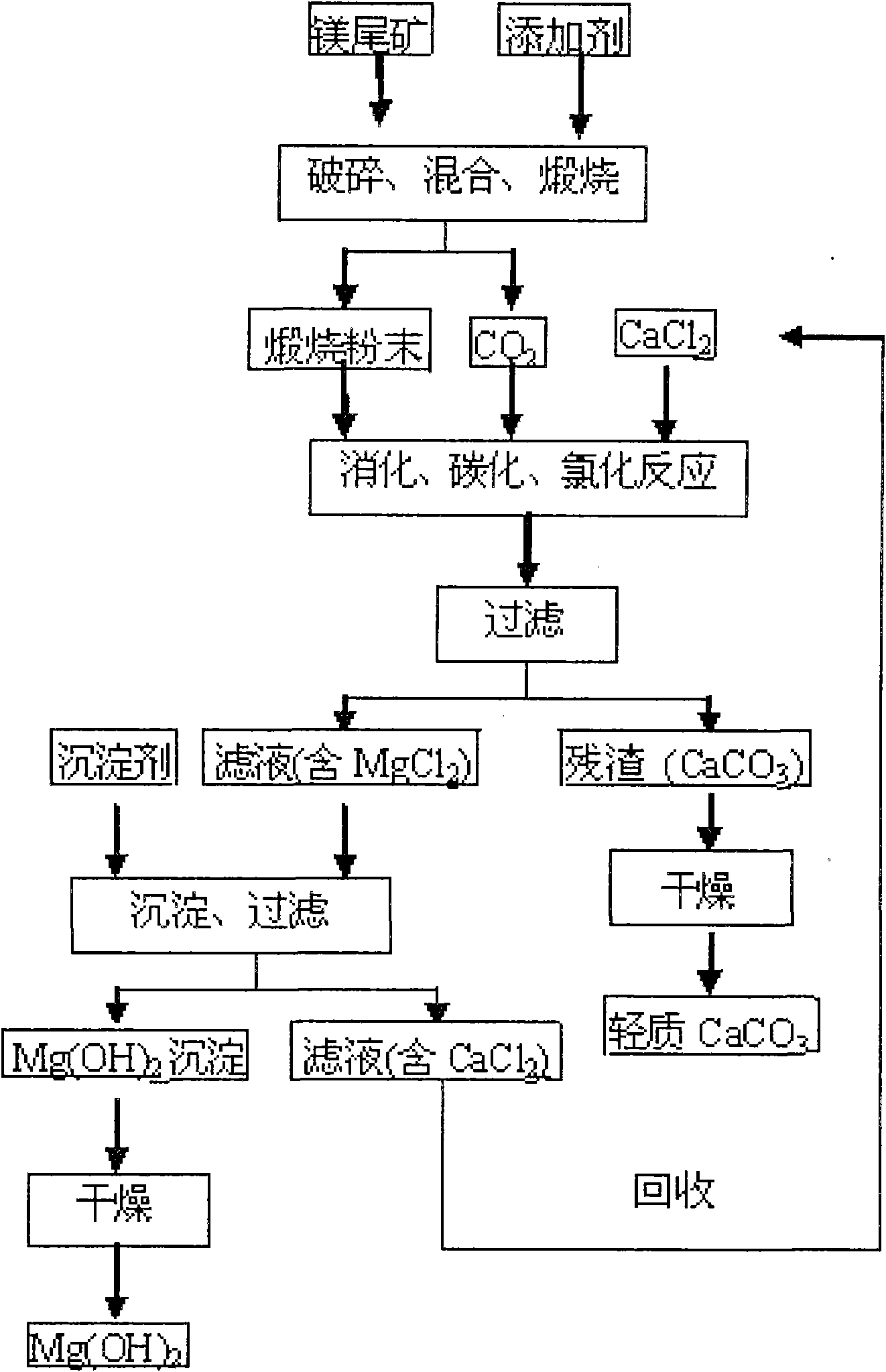

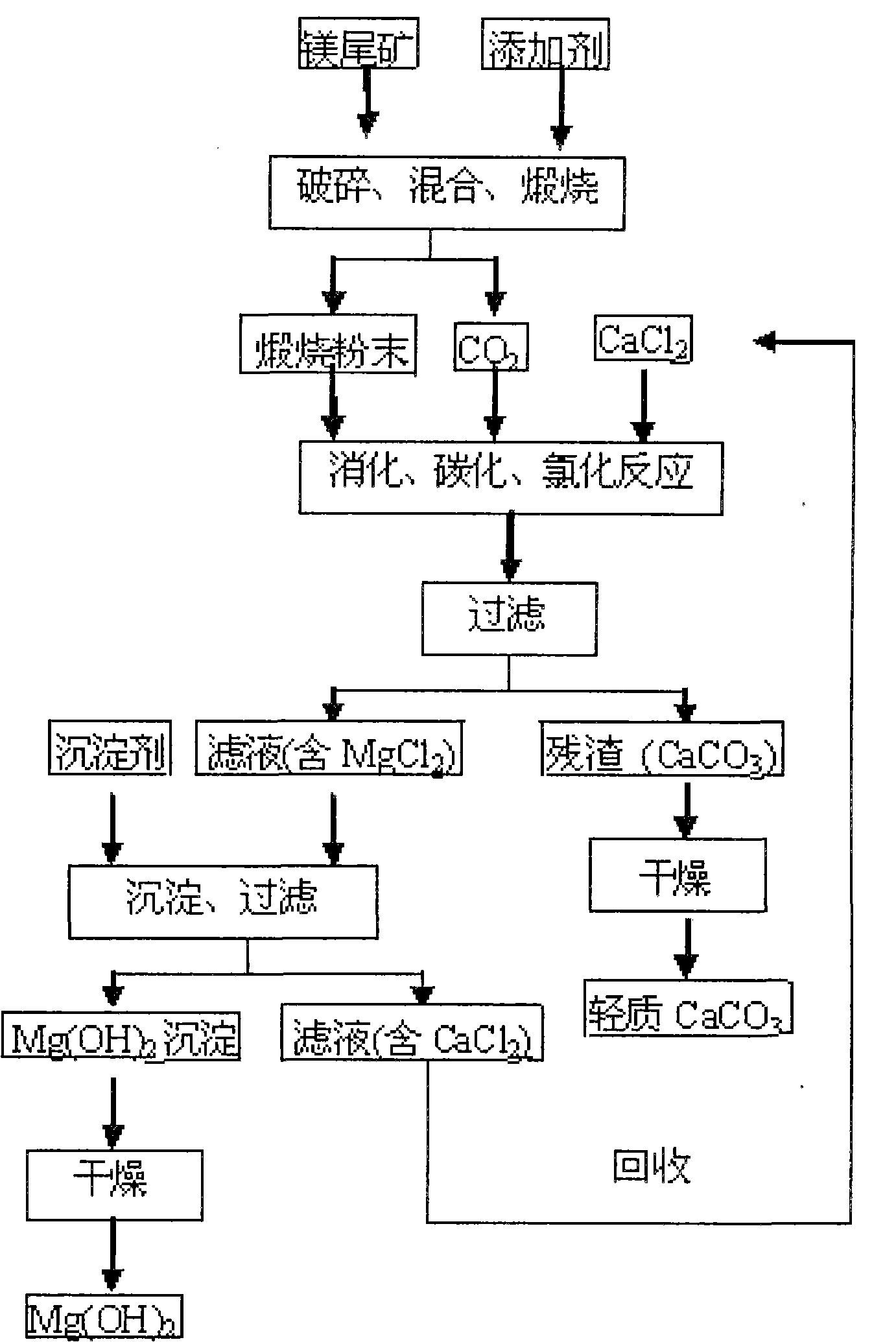

Method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings

A technology of light calcium carbonate and magnesium hydroxide, which is applied to the removal of magnesium hydroxide, calcium carbonate/strontium/barium, solid waste, etc., can solve pollution and other problems, and achieve safe operation, low impurity MgO content, and good reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The bulk magnesium tailings (calcium oxide content accounts for 24%) are crushed to obtain small pieces with a diameter of 16 to 19 mm, which are uniformly mixed with an additive of 1.4% by weight, wherein the additive is calcium chloride, and the additive The source of the calcium chloride solution is: the part of the calcium chloride solution mentioned in step (2) is obtained after evaporation and drying; then the mixture of the above-mentioned small magnesium tailings and additives is calcined at 670 ° C for 70 minutes to obtain calcined powder (mainly containing MgO and CaCO 3 ) and CO 2 , where CO 2 For subsequent digestion, carbonization and chlorination reactions;

[0029] (2) The calcined powder and calcium chloride solution were digested, carbonized, and chlorinated in a carbon dioxide atmosphere and stirred at 60°C for 120 minutes (the pH at the end of the reaction was 6.6-7.4), and then the solid-liquid separation was performed to obtain MgCl-containing...

Embodiment 2

[0033] (1) The bulk magnesium tailings (calcium oxide content accounts for 21%) are crushed to obtain small pieces with a diameter of 0.3 to 5 mm, which are uniformly mixed with an additive of 1.1% by weight, wherein the additive is calcium chloride, and the additive The source is: chemical reagent calcium chloride; then the mixture of the above-mentioned small magnesium tailings and additives is calcined at 840°C for 130min to obtain calcined powder (mainly containing MgO, CaO and CaCO 3 ) and CO 2 , where CO 2 For subsequent digestion, carbonization and chlorination reactions;

[0034] (2) The calcined powder and calcium chloride solution were digested, carbonized, and chlorinated for 80 minutes under the condition of stirring in a carbon dioxide atmosphere and 25°C (the pH at the end of the reaction was 6.6-7.4), and then the solid-liquid separation was carried out to obtain MgCl-containing 2 solution and CaCO 3 Precipitation; wherein the molar ratio of calcium chloride ...

Embodiment 3

[0038] (1) The bulk magnesium tailings (calcium oxide content accounts for 28%) are crushed to obtain small pieces with a diameter of 11 to 14 mm, which are uniformly mixed with an additive of 0.7% by weight, wherein the additive is magnesium chloride, and the source of the additive is It is: the part of the magnesium chloride solution mentioned in the step (2) is obtained after evaporation and drying; then the mixture of the above-mentioned small magnesium tailings and additives is calcined at 770°C for 30min to obtain calcined powder (mainly containing MgO, CaO and CaCO 3 ) and CO 2 , where CO 2 For subsequent digestion, carbonization and chlorination reactions;

[0039] (2) The calcined powder and calcium chloride solution were digested, carbonized, and chlorinated in a carbon dioxide atmosphere and stirred at 40°C for 100 minutes (the pH at the end of the reaction was 6.6-7.4), and then the solid-liquid separation was performed to obtain the MgCl-containing 2 solution an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com