Internal discharge detection method of sulfur hexafluoride gas insulation equipment

A technology for sulfur hexafluoride gas and detection methods, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of judging methods of unformed characteristic decomposition products or warning content values, so as to improve maintenance efficiency and increase Detection method, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The invention discloses a method for detecting internal discharge of sulfur hexafluoride gas insulated equipment based on the detection of trace chemical decomposition products, which can judge whether internal discharge or partial discharge occurs inside the GIS according to the decomposition products of sulfur hexafluoride; , Medium and low energy internal discharges and partial discharges can all be detected by the invention.

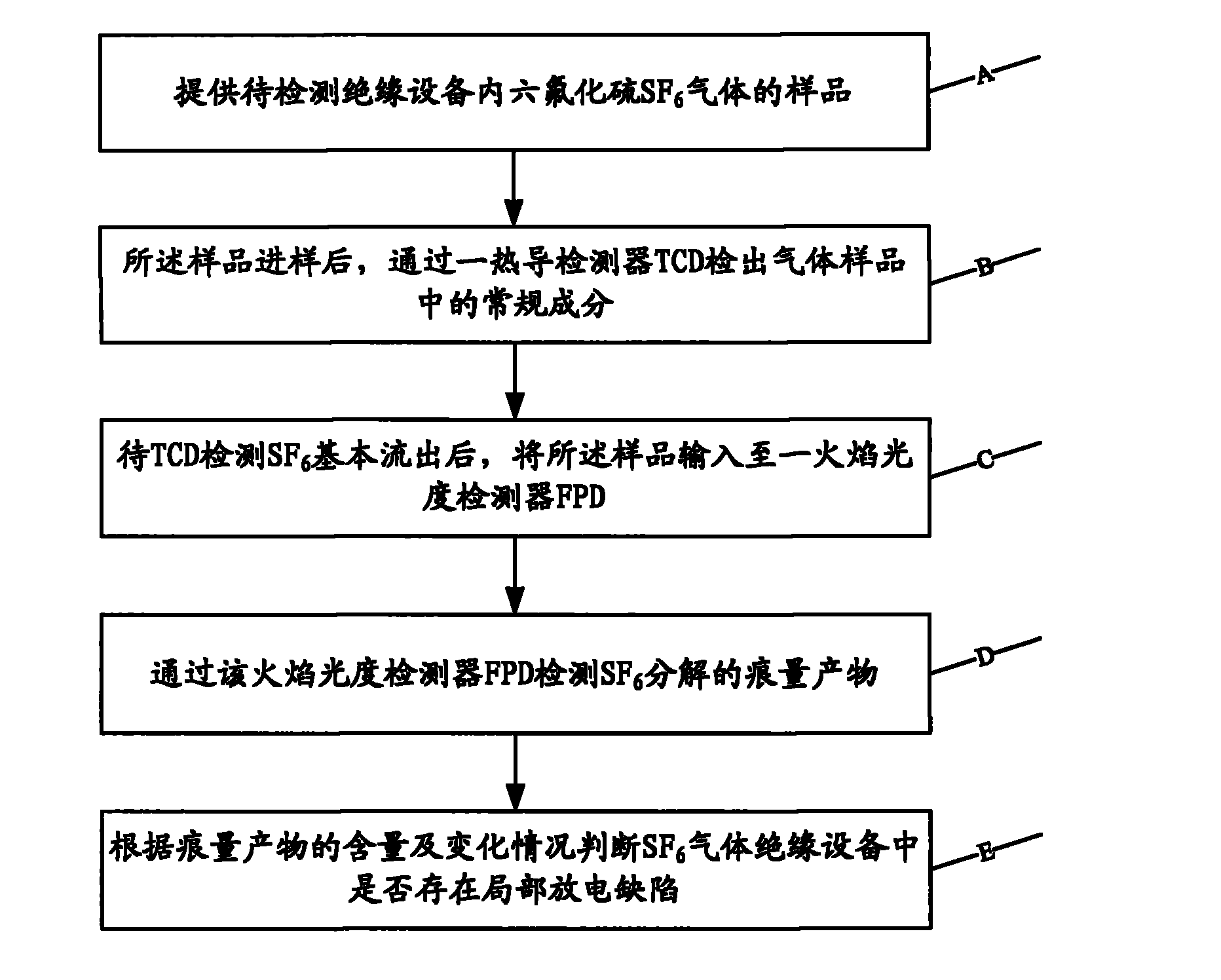

[0027] see image 3 , the internal discharge detection method of sulfur hexafluoride gas insulated equipment of the present invention comprises the following steps:

[0028] A. Provide sulfur hexafluoride SF in the insulation equipment to be tested 6 gas samples;

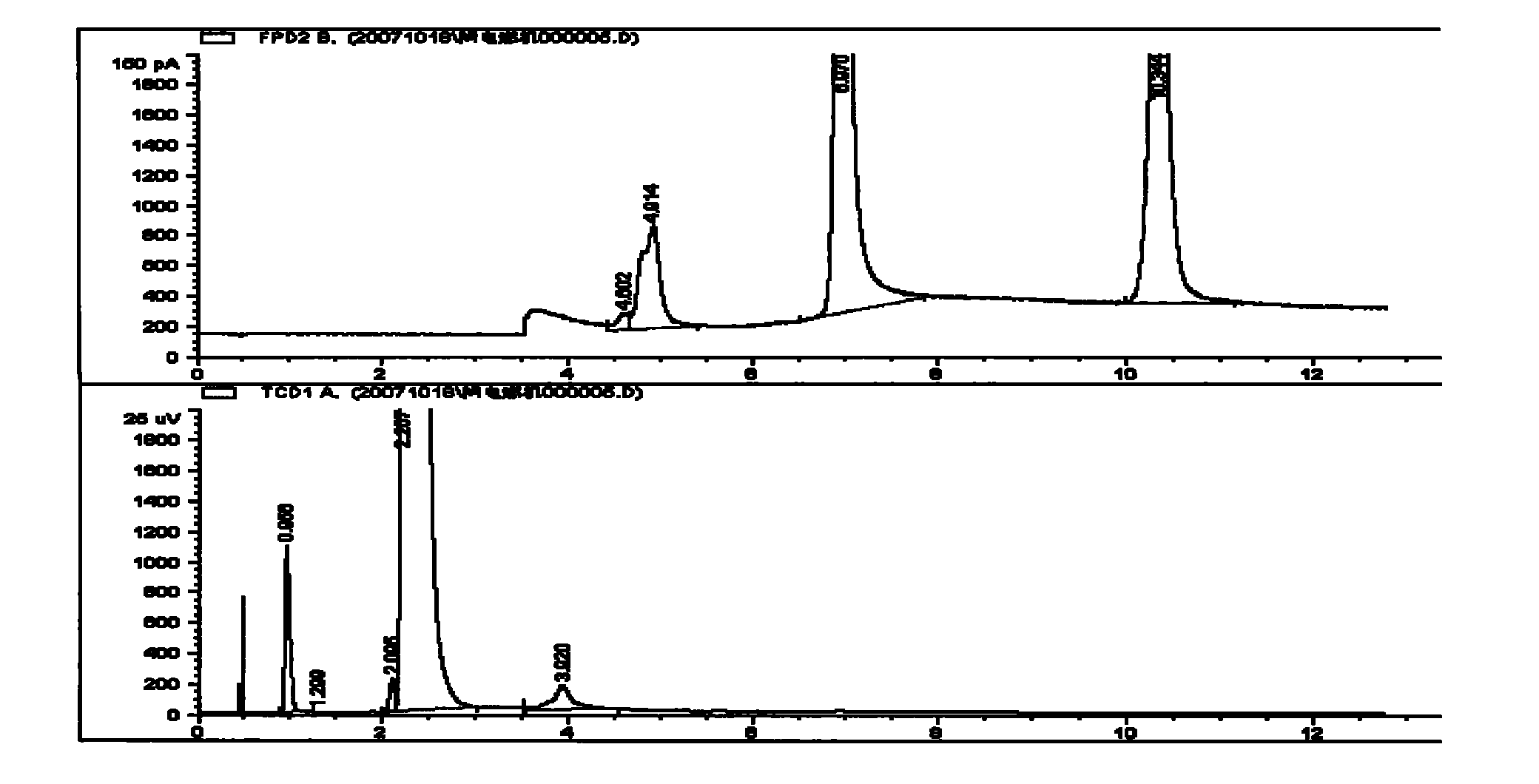

[0029] B. After the sample is injected, a thermal conductivity detector (TCD) is used to detect the conventional components in the gas sample; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com