Continuous counter-current organosolv processing of lignocellulosic feedstocks

A technology of lignocellulose and organic solvent, applied in the field of lignofiber feedstock fractionation into components, can solve the problems of low value, expensive pretreatment steps, unreasonable economy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

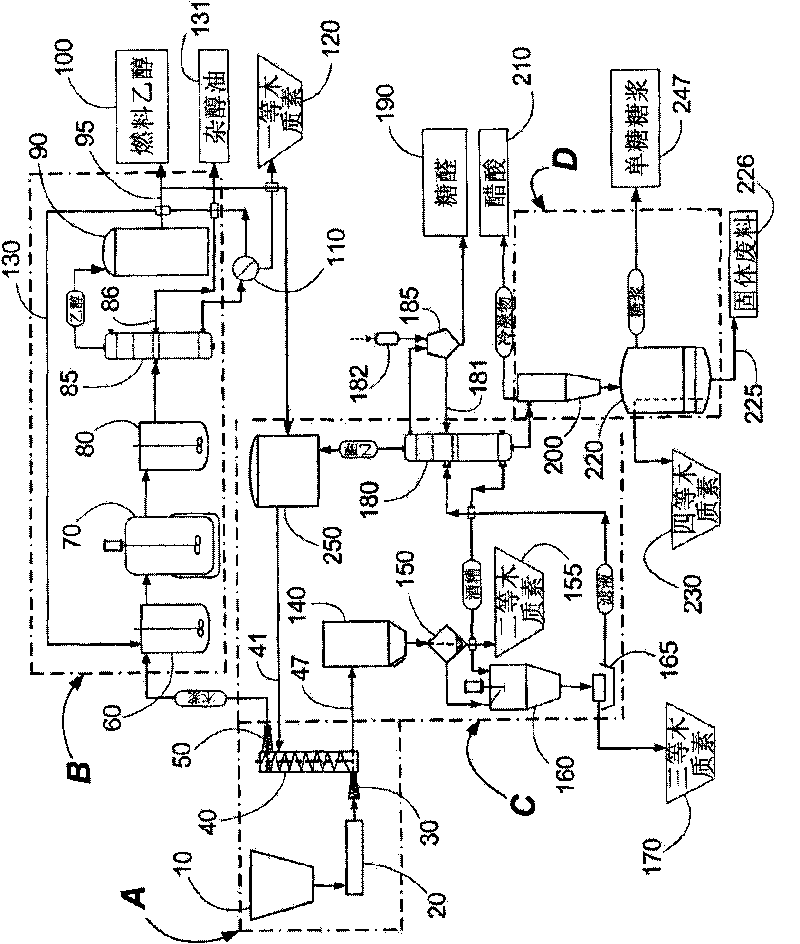

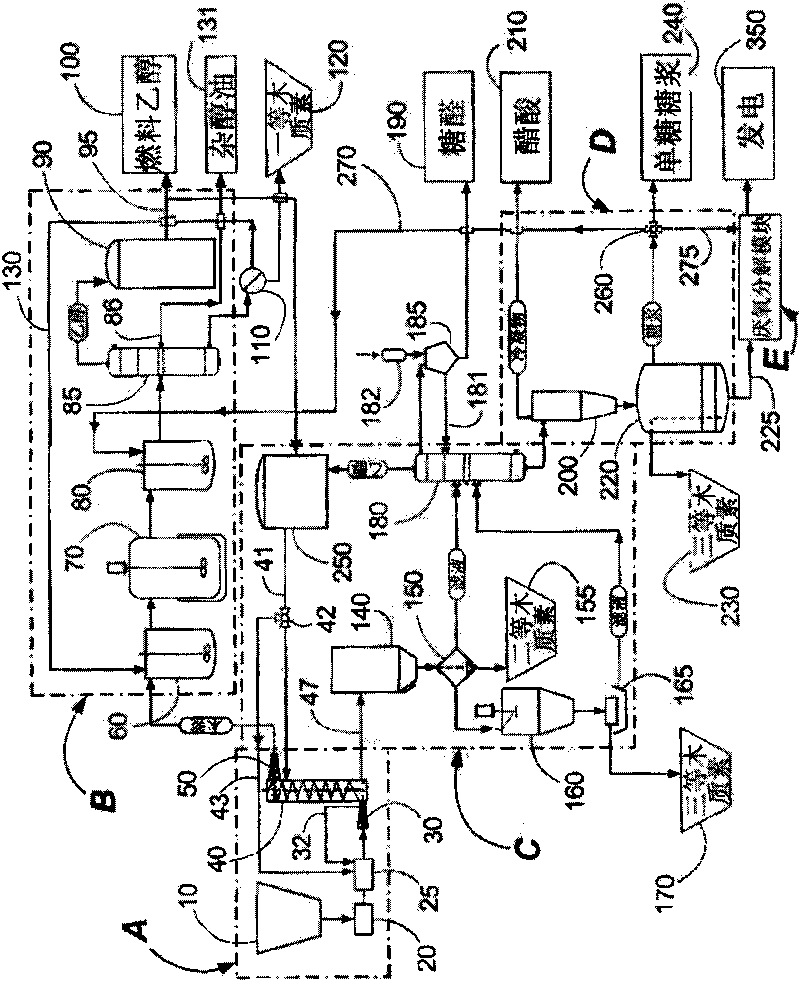

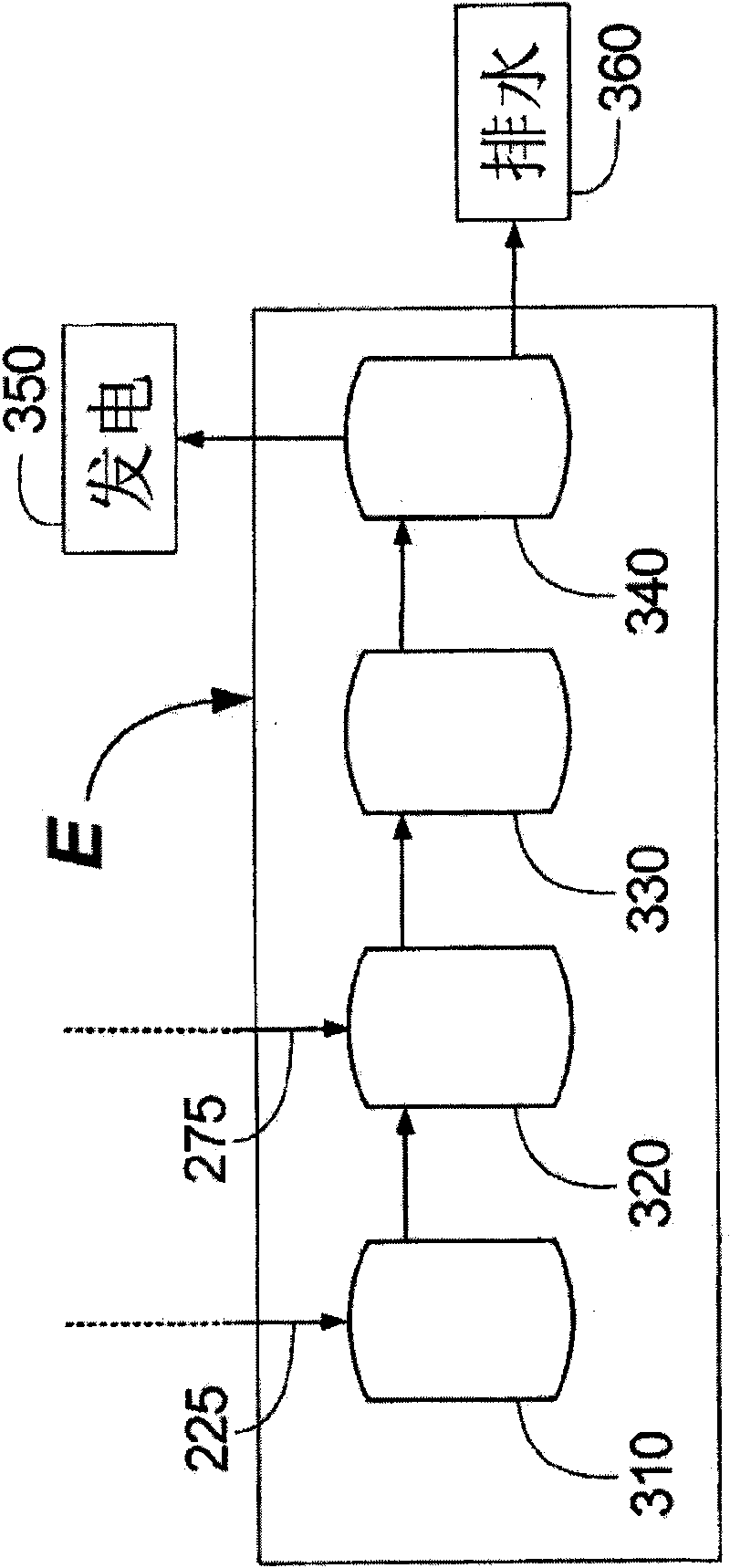

Method used

Image

Examples

example 1

[0059] A representative sample of British Columbia aspen (Pulus aspen) (~125 years old) whole logs was collected. After felling, the logs were unloaded, split, chipped and ground to a chip size of approximately (Parr is a registered trademark of Parr Instruments Inc., Moline, IL, USA) Poplar chips were pretreated in a reactor with organic solvents in hydroalcoholic (50% w / w ethanol) without the addition of external acids or bases. A replica 200 g (ODW) sample of poplar wood chips designated ASP1 was cooked at 195°C for 60 minutes. The black liquor:wood ratio was 5:1 by weight. After cooking, the reactor was cooled to room temperature. The solids and spent liquid are then isolated by distillation. The solid was washed vigorously with hot ethanol solution (70° C.), followed by a tap water wash step. The moisture content of the cleaned pulp is reduced to about 40% by means of a hydraulic press (optionally a screw press). Homogenize the washed wood pulp and store it in a refr...

example 2

[0068] A replica 200-g sample prepared in Example 1, designated as ASP2 sawdust, was used in this study. in 2-L The aspen sawdust was pretreated in the reactor with an organic solvent in hydroalcoholic (50% w / w ethanol) without adding an external acid or alkali. A replica 200 g (ODW) sample of poplar wood chips was boiled at 195°C for 90 minutes. The black liquor:wood ratio was 5:1 by weight. After cooking, the reactor was cooled to room temperature. The solids and liquids are then isolated by distillation. The solid was washed vigorously with hot ethanol solution (70° C.), followed by a tap water wash step. The moisture content of the cleaned pulp is reduced to about 40% by means of a hydraulic press (optionally a screw press). Homogenize the washed wood pulp and store it in a refrigerator at 4 °C. Virgin wood chips, washed and unwashed wood pulp were determined according to the modified Klason lignin method obtained from the Technical Association of the Wood Pulp and ...

example 3

[0076] A replica 200-g sample prepared in Example 1, designated as ASP3 sawdust, was used in this study. in 2-L The aspen sawdust was pretreated in the reactor with an organic solvent in hydroalcoholic (50% w / w ethanol) without adding an external acid or alkali. Replica samples of poplar wood chips were boiled at 195°C for 120 minutes. The black liquor:wood ratio was 5:1 by weight. After cooking, the reactor was cooled to room temperature. The solids and liquids are then isolated by distillation. The solid was washed vigorously with hot ethanol solution (70° C.), followed by a tap water wash step. The moisture content of the cleaned pulp is reduced to about 40% by means of a hydraulic press (optionally a screw press). Homogenize the washed wood pulp and store it in a refrigerator at 4 °C. The chemical composition (hexose, pentose, lignin content) of virgin wood chips, washed and unwashed wood pulp was determined according to the modified Klason lignin method obtained fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com