Ternary CoFeCr hydrotalcite nanorod and preparation method and application thereof

A nanorod and hydrotalcite technology, applied in nanotechnology, chemical instruments and methods, electrodes, etc., can solve the problems of poor oxygen evolution performance of electrolytic water, complicated preparation process, and low production efficiency, and achieve good oxygen evolution performance of electrolytic water , simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

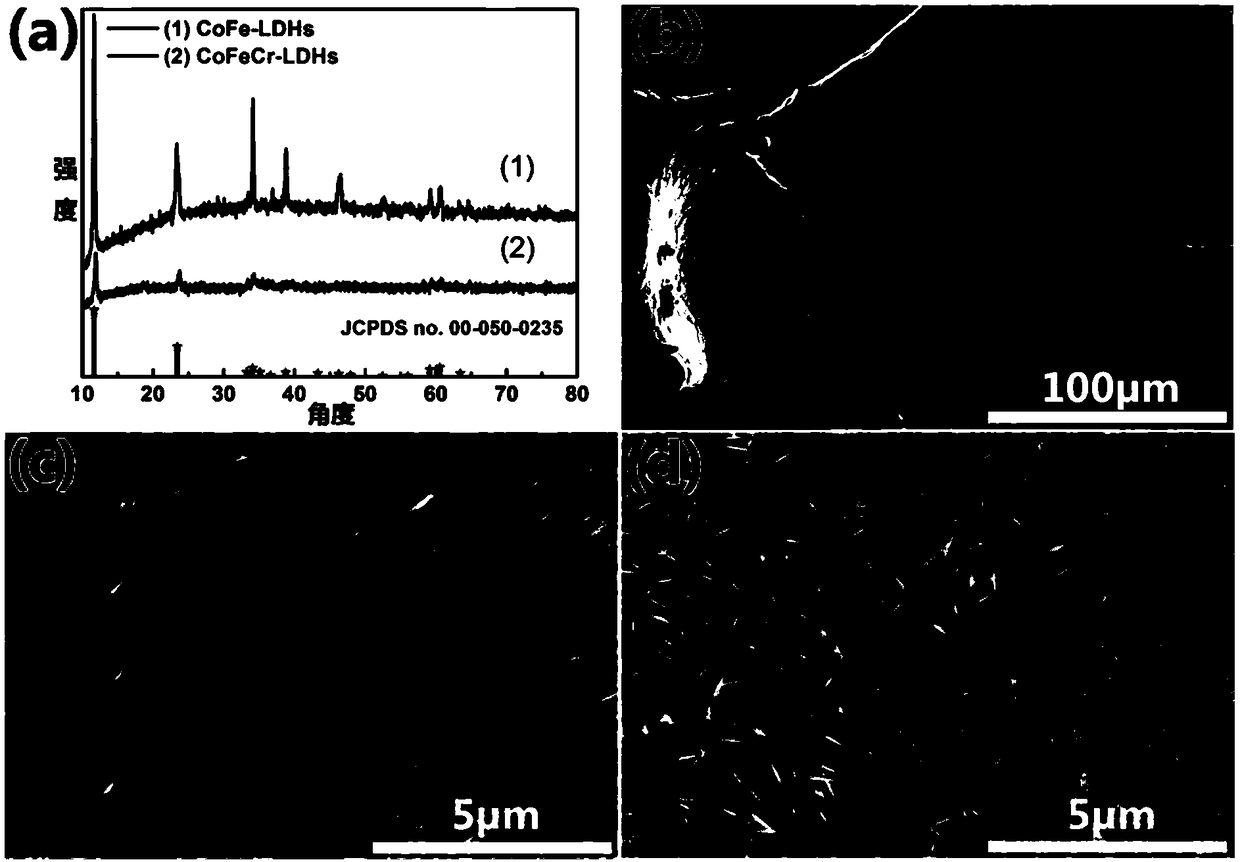

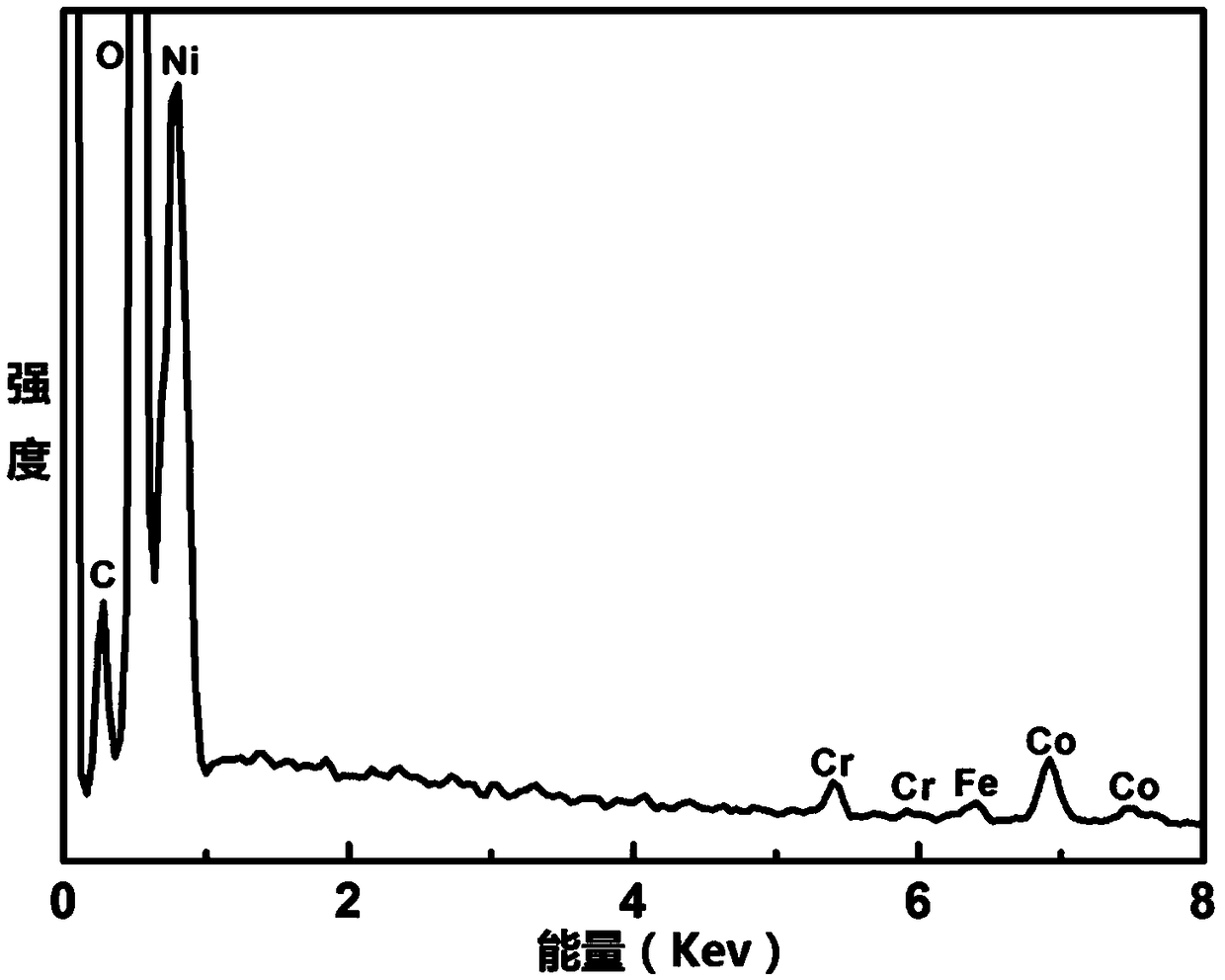

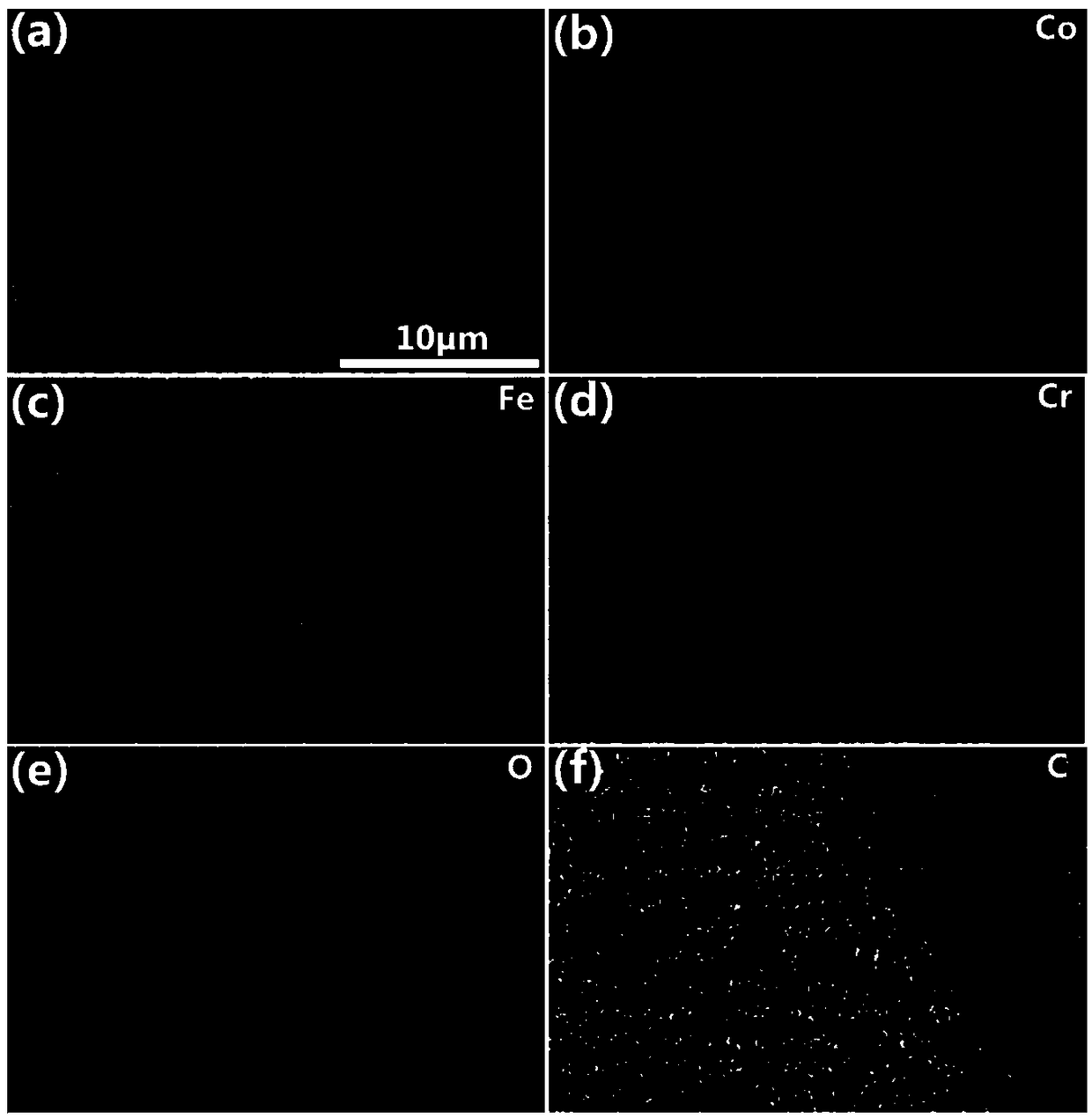

[0023] A kind of ternary CoFeCr hydrotalcite nanorod, its preparation method comprises the following steps:

[0024] Step A, mix cobalt nitrate, ferric nitrate, chromium nitrate, urea, ammonium fluoride together in water, make the concentration of cobalt nitrate in the solution after mixing be 40~80 mmol / liter, the concentration of ferric nitrate be 8~20 The concentration of chromium nitrate is 8-20 mmol / liter, the concentration of urea is 0.5-0.8 mole / liter, and the concentration of ammonium fluoride is 0.2-0.3 mole / liter, so as to prepare the precursor mixed solution.

[0025] Step B, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution into an autoclave, and then reacting at 110-130° C. for 360-600 minutes, so that the substrate Ternary CoFeCr hydrotalcite nanorods (that is, CoFeCr-LDHs nanorods) were prepared.

[0026] Wherein, the substrate can be nickel foam (Nickel Foam, NF), copper foam, carbon cloth or...

Embodiment 1

[0035] A kind of ternary CoFeCr hydrotalcite nanorod, its preparation method comprises the steps:

[0036] Step a, mix cobalt nitrate, ferric nitrate, chromium nitrate, urea, ammonium fluoride together in water, make the concentration of cobalt nitrate in the solution after mixing be 60 mmol / liter, ferric nitrate concentration be 10 mmol / liter, nitric acid The concentration of chromium is 10 mmol / L, the concentration of urea is 0.6 mol / L, and the concentration of ammonium fluoride is 0.25 mol / L, so as to prepare the precursor mixed solution.

[0037] Step b, using nickel foam with a size of 1×4cm as the substrate, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution to a 25mL autoclave, and then The reaction was carried out at 120°C for 480 minutes to prepare ternary CoFeCr hydrotalcite nanorods on the nickel foam substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com