Phosphorus-containing compound, and preparation method and application thereof

A composite and composite electrode technology, which is applied in the fields of material science and chemistry, and can solve the problems of corrosiveness and high flammability of trioctylphosphine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

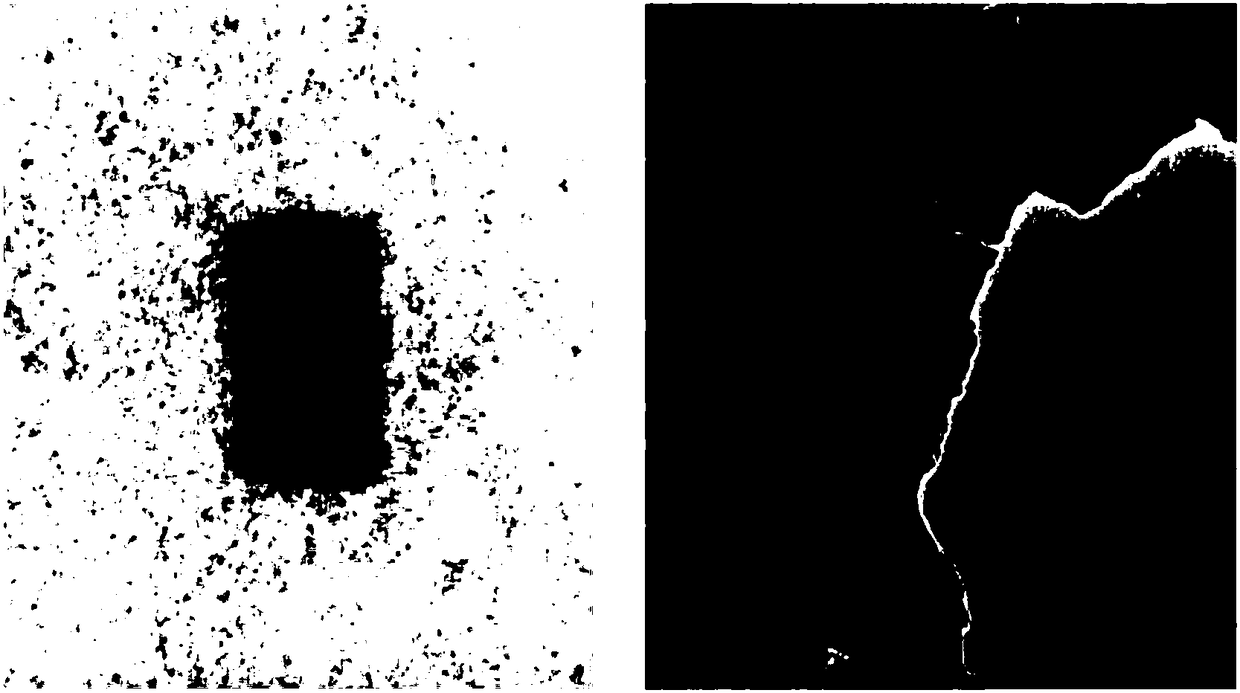

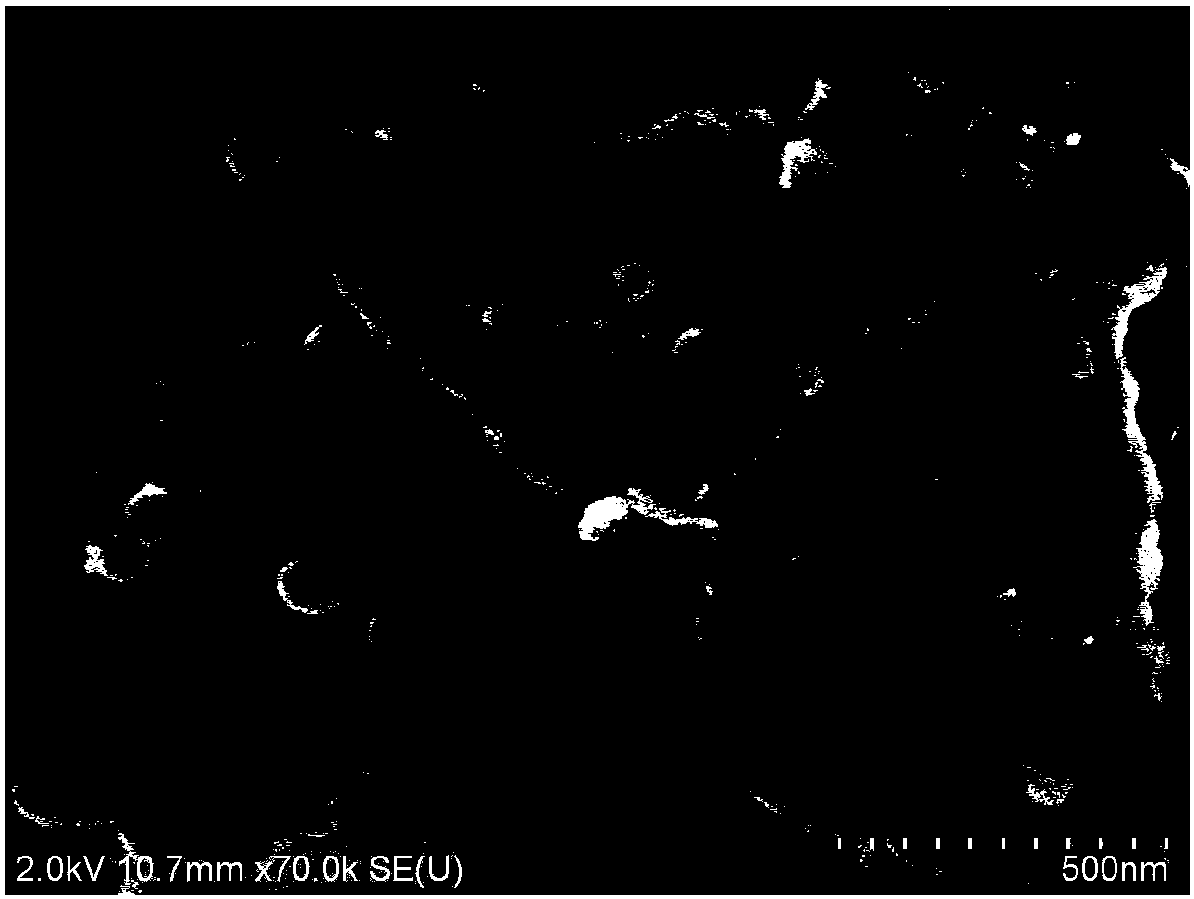

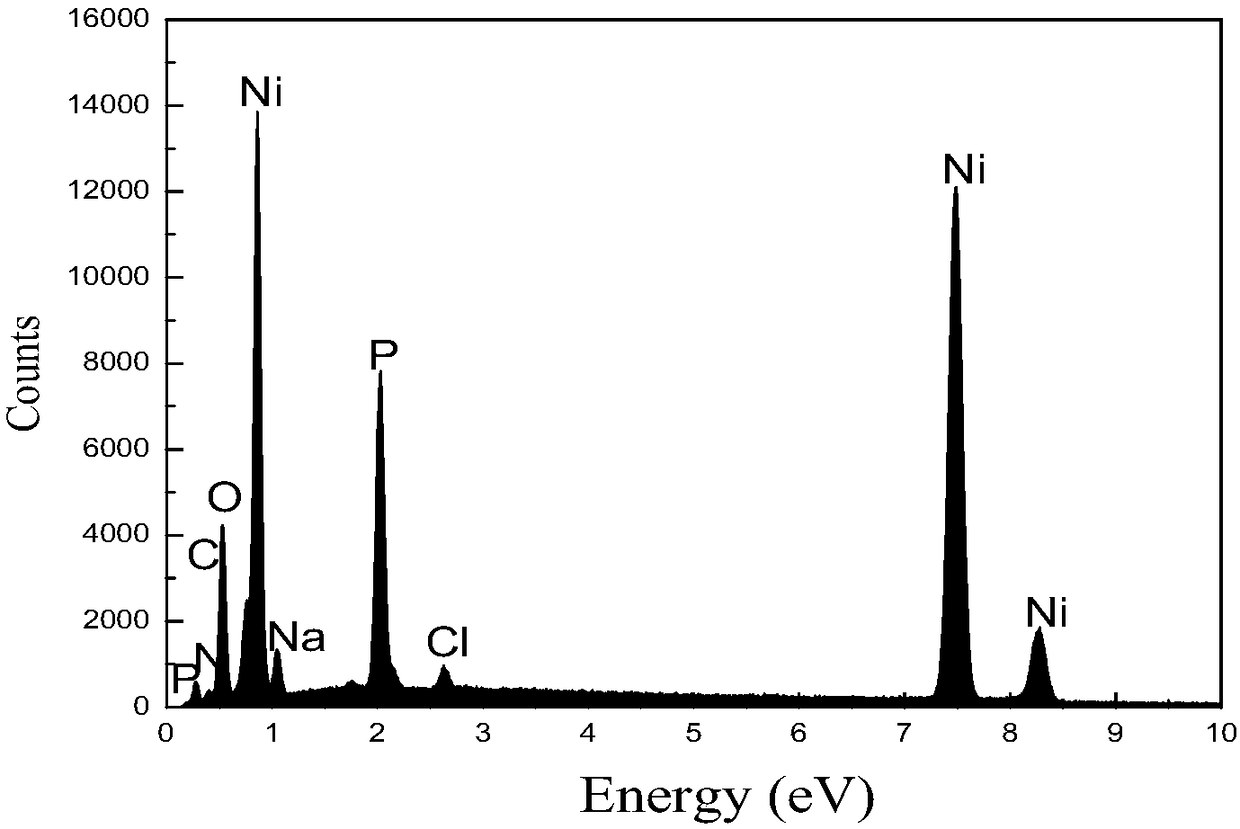

[0115] Example 1: NixP@g-C 3 N 4 Catalyst and NixP@g-C 3 N 4 / NF electrode preparation and characterization

[0116] New NixP@g-C 3 N 4 The preparation steps of / NF electrode are as follows:

[0117] (1) Firing g-C 3 N 4

[0118] First, weigh a certain amount of thiourea and place it in a crucible, then place the crucible in a muffle furnace and heat it up to 550°C (heating rate 2°C / min) and keep it for 2h. Grind the yellow solid in a porcelain mortar for a certain period of time, then pour it back into a crucible, place it in a muffle furnace and heat it up to 500°C (heating rate 2°C / min) and keep it there for 2 hours, then take out the crucible after cooling down to room temperature, and grind the yellow-white powder A certain time, this is g-C 3 N 4 .

[0119] (2) Pretreatment of nickel foam

[0120] 1×2cm nickel foam was ultrasonically pretreated in 3mol / L hydrochloric acid solution, acetone, deionized water and ethanol solution for 15 minutes, washed three ti...

Embodiment 2

[0129] Example 2: NixP@g-C 3 N 4 Electrochemical performance test comparison between / NF electrode and other electrodes

[0130] (1) Preparation of other electrodes:

[0131] Get g-C among the embodiment 1 3 N 4 Put 10mg into a 250mL beaker, add 10mg magnesium nitrate hexahydrate and 100mL isopropanol solution, and sonicate for 3h. The above solution is used as the electrophoresis liquid, nickel foam is used as the cathode, and the platinum electrode is used as the anode in the electrophoresis instrument for 10 minutes, and the prepared electrode is taken out and rinsed with deionized water, and dried, that is, g-C 3 N 4 / NF electrode.

[0132] In order to further compare catalyst performance, 20wt% commercial Pt / C catalyst is dispersed in the solution of ethanol and water, the volume ratio is 4:1, then add 40 microliters of Nafion solution, supergene 20min, then the above-mentioned mixed homogeneous The phase catalyst was loaded on the nickel foam, and finally, the sam...

Embodiment 3

[0137] Embodiment 3: Based on Ni X P@g-C 3 N 4 Electrodes of different substrates

[0138] (1) get g-C in embodiment 1 3 N 4 Put 10mg into a 250mL beaker, add 10mg magnesium nitrate hexahydrate and 100mL isopropanol solution, and sonicate for 3h. Use the treated FTO and copper sheet as the cathode, and the platinum electrode as the anode in the electrophoresis apparatus for 10 minutes, take out the prepared electrode, rinse it with deionized water, and dry it. Add 14mL of sodium hypophosphite solution (0.2mol / L) and 4mL of nickel chloride (0.1mol / L) into a 25mL round bottom flask, then add 2mL of deionized water, shake well, put the prepared electrode into the flask Then, nitrogen gas was passed into the sealed flask for 40 minutes to remove impurities such as oxygen. Then put the flask under a 300W xenon lamp for light, and stir evenly during the light. After the reaction, rinse with deionized water and dry. Namely get NixP@g-C respectively 3 N 4 / FTO and NixP@g-C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com